Modix announced a series of convenience and functional features for their line of 3D printers.

The Israeli company has been developing large format FFF 3D printers for several years, and today seems to have no less than six different models in their catalog. CEO Shachar Gafni told us:

“During mid-2020 we have tripled our product lineups from only two models to a total of six. These models were accepted very respectfully by the market. As a result, we have continued our 50% rapid annual growth deep into 2021, a third year in a row.”

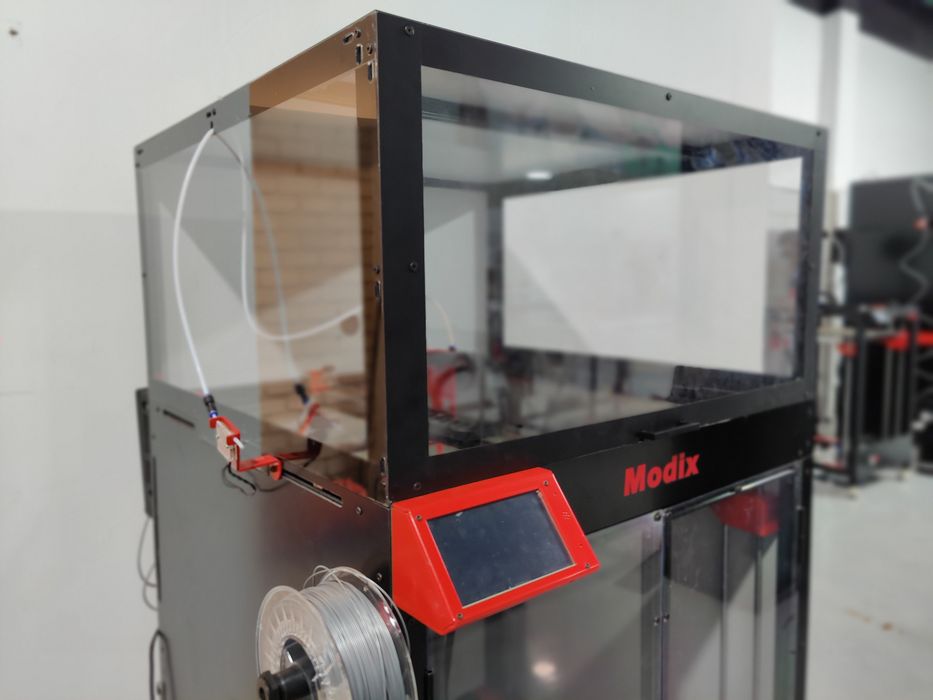

Their lineup now includes the truly massive BIG-180X, which has an incredible build volume of 1800 x 600 x 600 mm. That’s large enough to build huge industrial parts, although it might take a while to complete the print job. This image provides an idea of this capability:

The six models range from the “small” BIG-40, with it’s build volume of “only” 400 x 400 x 800 mm, all the way up to the BIG-180X (seen at top).

In addition to the new 3D printer models, the company has been busy refining several new features to be optionally installed with new orders. Gafni explained:

“Since the release we have been listening to our end-customers and reselling partners, addressed their main pain points and we have shifted our attention on bringing solutions. Six of these projects are now ready and already available through a pre-order campaign. We’re bringing fully automatic motion-system calibration with the click of a button, removable magnetic bed, clog and crash detector, wire management and a taller top lid. All of these serves our users by increasing print reliability and improving their printing experience.”

The new optional features include:

Fully Automated Calibration

This features not only mesh bed leveling, but also bed tilt calibration (something more important for larger machines) and gantry alignment. All of this is activated at the touch of a button.

Removable Magnetic Bed

This is a feature we’re seeing on an increasing number of machines. It enables operators to quickly remove a full print plate and twist to remove all the parts. It’s a huge time saver for other machines, and certainly will do the same for Modix gear.

Clog Detector

This seems to be a sensor system that monitors the flow of filament. If it is disrupted in any way — beyond the mere presence detection in other devices — warnings are triggered. For example, if there is a slight clog that slows the flow down slightly, this will be noticed. That type of problem would not be detected on most other 3D printers.

Crash Detector

Most 3D printers have a mechanism to prevent head crashes into the print bed, but Modix has added a second detection system to fully ensure this will absolutely never happen. Personally, I hate head crashes.

Showroom Top Lid

This feature is a transparent case the fits around the 3D printer, replacing the standard version. It allows the machine to safely operate without fingers getting involved in the print job, but also permits viewing and lighting of print activity from all sides. Modix said this feature would be useful for trade shows and training situations.

Power Distribution Unit

This seems to be a cable management solution that was previously included only on Modix’s larger units. Now it is available for all machines in their lineup. Apparently everyone needs a cable management solution, regardless of machine size.

Modix Activity

The company has been rapidly developing their internal systems to allow for more efficient processing. Gafni explained:

“Since our machines are quite large and heavy, the raise of logistics costs and long supply delays has made our daily logistics operation much more complicated. As a result, we had to mature very fast like the implementation of five global warehouses and a unified information system based on Oracle Netsuite, and another leading unified global logistics management platform.”

Regarding the future, Gafni sees both growth and challenges on the way:

“Due to the public exposure that 3D printing has received during the start of the Covid pandemic we see an increase of interest from new manufacturing companies looking for new way to integrate 3d printing into their production lines. However, changing your manufacturing processes and real-life integration of 3D printing will take time and will require a lot of patience and hard work.”

What’s in store for Modix’s products in the future? Gafni didn’t tell us any details, but hinted at what might be coming:

“There will be a lot of attention on becoming a technology leader in all offering aspects including speed, quality, versatility, reliability and of course service.

More than a few additional developments are now in progress and will be released in the upcoming months. For example, we are integrating fast servo motors, a high flow extruder and a heated chamber. These and other new features will extend our offering towards high-end production solutions made with engineering grade filaments.”

I’m interested to see the new improvements.

Via Modix