Charles R. Goulding and Preeti Sulibhavi look at an example of how 3D printing technology changed telemedicine during the pandemic.

The pandemic drove tremendous demand for telemedicine services. Technology has enabled patients and medical service providers to become more comfortable with telemedicine. The all-important medic reimbursement codes were revised to include telemedicine services. The telemedicine participation rate for a broad spectrum of medical services increased, including most medical specialties plus mental and dental medical services.

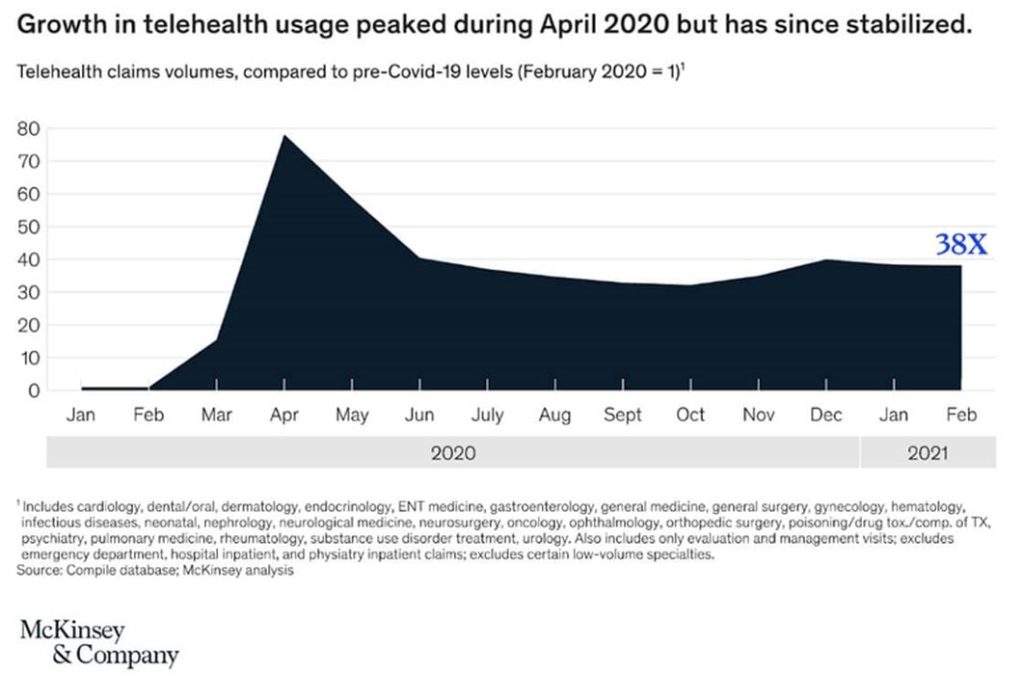

Overall, the telemedicine category increased an astonishing 38X from pre-pandemic levels. McKinsey, the leading consulting firm, presented the growth increase in the following graph. The size of this new service category supports new medical products.

One new product recently announced by Nexa3D, French med-tech startup, WeMed, and Henkel, is a 3D printed stethoscope.

French startup WeMed was founded during the early days of the Covid-19 epidemic precisely to respond to accelerating demand for new diagnostic medical devices that support teleconsulting and remote monitoring. Nexa3D and Henkel came together with French contract manufacturer Third to help WeMed develop, manufacture, and launch its new product.

Produced on the NXE 400 ultrafast 3D printer using performance-matched Henkel materials, the WeMed Skop is the world’s first connected stethoscope to be additively manufactured in its entirety at scale. Annual production volumes will exceed 100,000 units, according to Nexa3D, which showcased Skop at RAPID + TCT 2021 at McCormick Place, Chicago, from Sept. 13 to 15.

This 3D printed medical device has great impact on health outcomes and the future of medicine itself. As the industry grows and evolves, 3D printing will find its way more and more in medical device development.

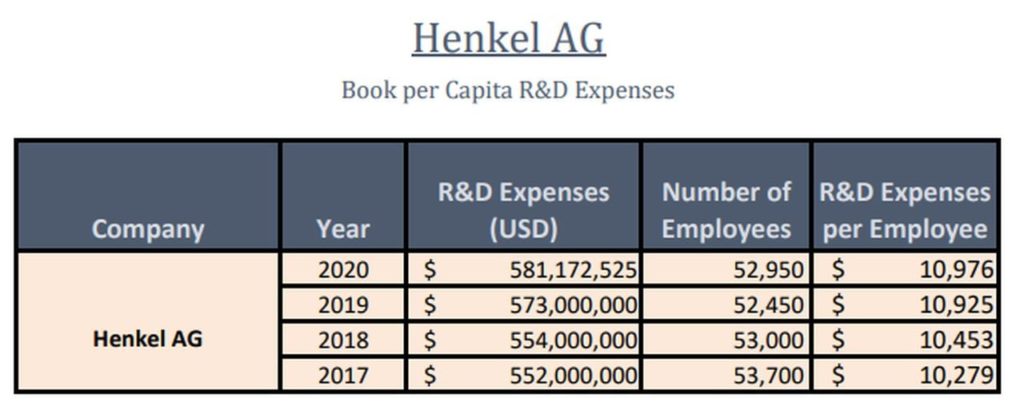

Henkel is a large German headquarter adhesives company known for a major commitment to R&D and to 3D printing.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Telemedicine became a great resource during the Covid-19 pandemic. It looks as though it is here to stay and be a great resource for many going forward. Telemedicine is also driving innovation in medical device design and development to allow for remote diagnosis and patient monitoring. 3D printing can be a part of this new aspect of medical care by fueling innovation in medical device development.