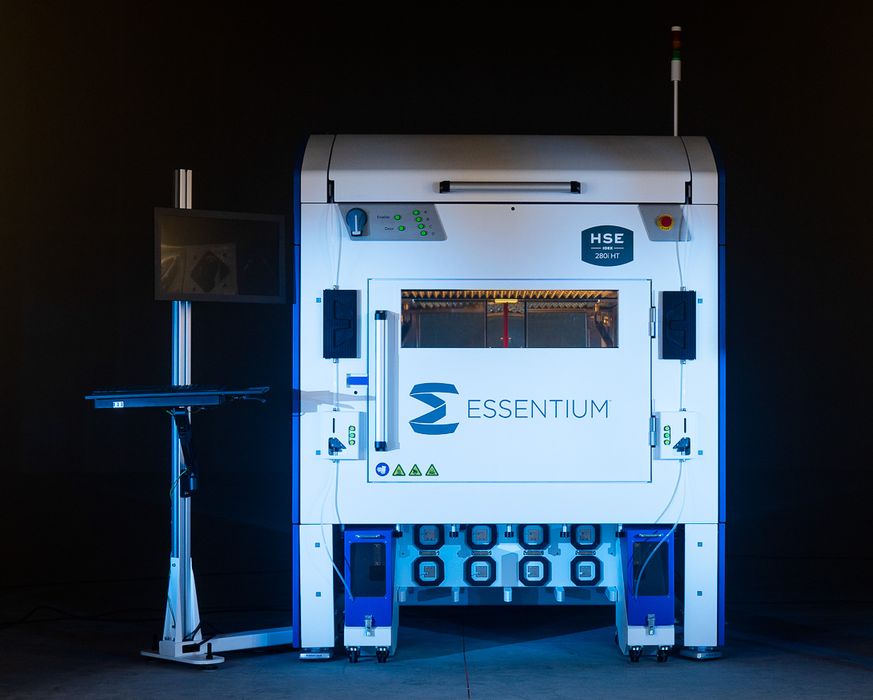

Essentium is set to reveal a milestone device at the upcoming Rapid+TCT exhibition.

The new machine is the HSE 280i HT, and while the name doesn’t differ much from their previous equipment, it includes a highly unusual feature not seen on 3D printers until now.

We’ll be getting additional information about the device in coming weeks, but for now this is what we know.

Like all Essentium systems, the HSE 280i HT is a very fast printing device. The company is well-known for its adaptation of high-speed semiconductor approaches for the 3D printing industry. These have been able to drive the speed of their motion systems quite high, and I’ve seen them myself in operation. By the way, that’s why their brand is “HSE”: High Speed Extrusion.

Essentium describes the speed of the new machine:

“The HSE 280i HT is equipped with a non-slip, high torque extrusion system and linear servo motors, delivering 5x – 15x the throughput of similar competitors.”

The HSE 280i HT is also a high temperature device. It will be able to handle many types of engineering materials with its enclosed build chamber and high temperature components.

Essentium said the device will be suitable for both prototyping and “full-scale production”.

But the key feature I’ve been hinting at is a new style of independent extrusion. This is where the 3D printer includes two extruders and toolheads, where each can move independently. Typically these are mounted on a single rail and can move laterally independent of each other.

But the new HSE 280i HT’s IDEX system is different. They explain:

“Designed to transform the factory floor, this groundbreaking industrial-level 3D printing system features independent dual extruders (IDEX). A first-of-its-kind, this true IDEX system is independent on both the Y and X axis, enabling manufacturers to 3D print multi-part builds at industrial speeds, even for parts with complex geometries.”

These extruders move independently on TWO AXES! This makes them truly independent of each other and thus there are many more possibilities for 3D printing operations.

Essentium explained the new machine has five different build modes:

- Single head mode (one toolhead prints alone, like most 3D printers)

- Support mode (one toolhead prints model material, while the other prints support material)

- Copy mode (two toolheads print copies of the same object)

- Independent mode (two toolheads do completely different sets of objects simultaneously)

- Multi-process mode (combinations of the above?)

If the “normal” high speed of the HSE equipment isn’t enough, the new IDEX concept should add to production throughput.

In a way, this is very much like having two machines in one, since a second toolhead can literally do a completely different build job than the first toolhead.

A production scenario might normally require a second job to wait for the first job to complete. However, the new IDEX concept could allow both jobs to co-exist within the build chamber and complete in parallel. This alone could be a significant speed-up for operations with varying styles of print jobs in their queue.

I have a suspicion that Essentium has made some interesting changes to their job setup software to allow for these unusual modes and job configurations.

I’m quite interested to learn more about this machine, and in particular want to see the motion system in action.

Via Essentium