Researchers have found a way to print liquid crystals with iridescence and polarization patterns.

Specifically, they have developed a “chiroptical photonic polymer” that exhibits these visual properties, according to their paper entitled, “Anisotropic Iridescence and Polarization Patterns in a Direct Ink Written Chiral Photonic Polymer”.

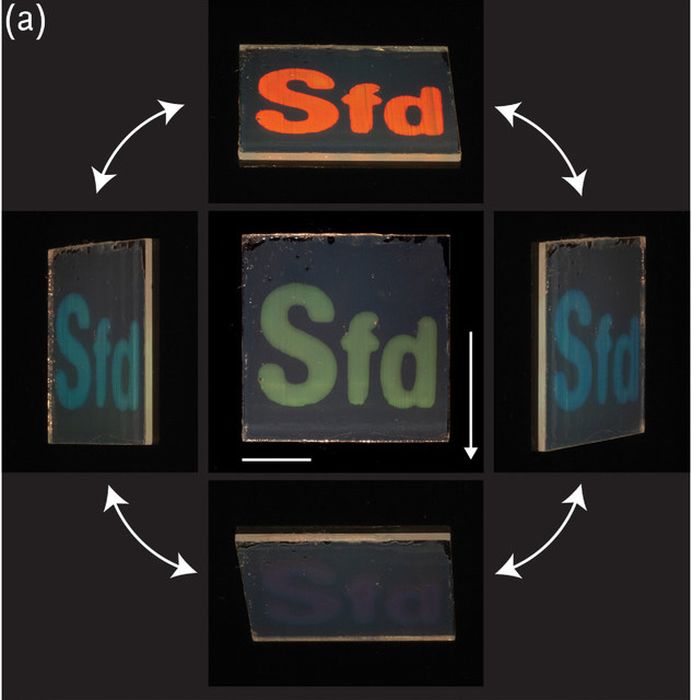

If you’re not sure what this is, it’s that peculiar iridescent lustrous colors you see in certain natural situations. For example, some insects have exoskeletons that exhibit unusual iridescence, as they are visually different depending on the angle of perspective.

In industry chiroptical (which refers to an optical process involving refraction, emission, or absorption of radiation) techniques are used in many ways. You’ll see examples of this type of material on credit cards, where they are used as a security feature. They are also used in certain types of optical sensors and other applications.

How do these materials work? It is an effect derived from the microstructure and configuration of molecules, which causes light to behave in these unusual ways.

While materials with these properties can occur naturally, there are “non trivial” industrial processes to produce thin-film versions with full control over the photonics properties.

But could such a material be 3D printed? It turns out researchers at The Eindhoven University of Technology have developed a way to do so.

The researchers worked with chiral nematic liquid crystals because they can self-assemble into proper alignments. They explain:

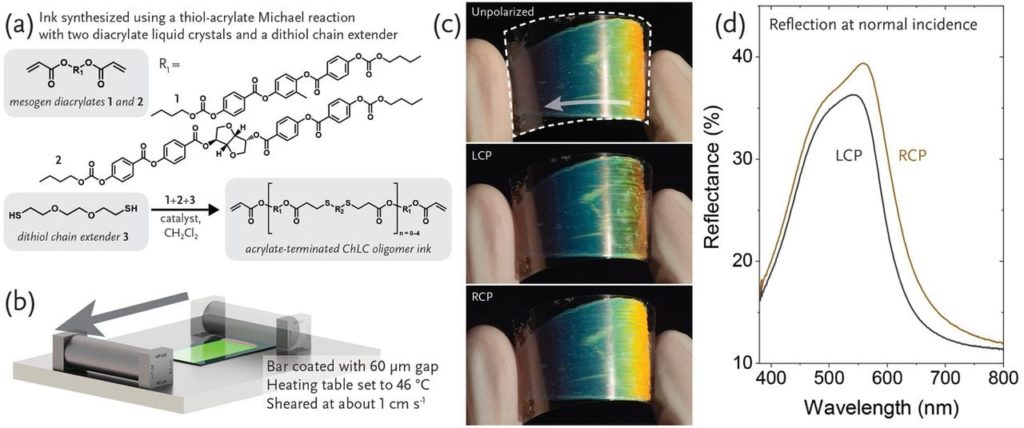

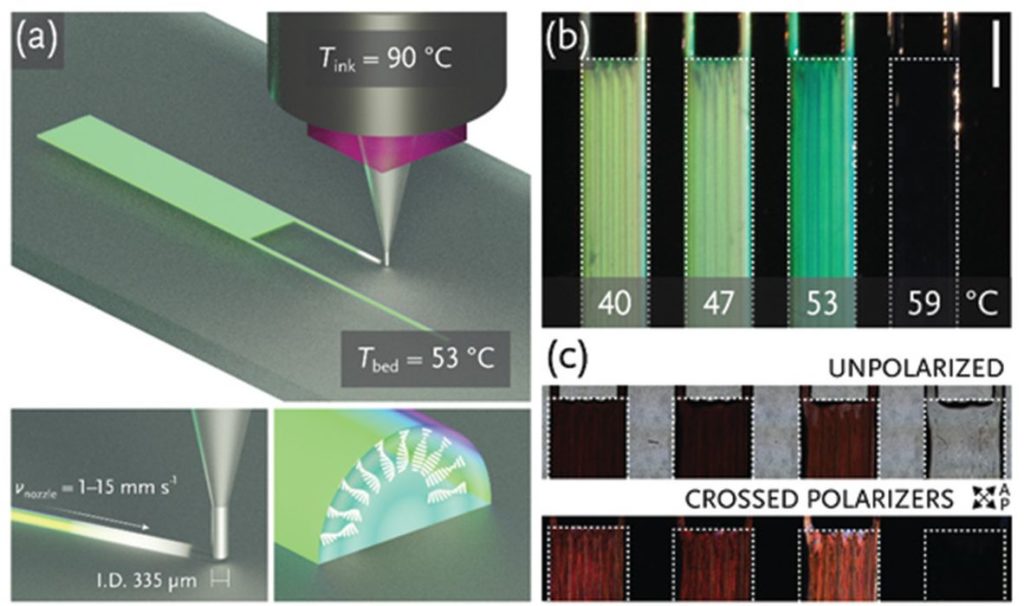

“In this work, we present a structurally colored, printable chiroptical material based on a ChLC oligomer “ink” synthesized from a reactive cholesteric LC. This ink combines straightforward processing with easy-to-exploit freedom in iridescence and circular polarization selectivity of reflected light on a voxel-by-voxel basis. After fashioning films on the order of 10 cm2 with bar coating, DIW is used for the generation of intricate, spatially defined optical patterns—DIW being a highly adaptable technique that deposits viscoelastic resins according to a computer-controlled print path. It is shown that the resulting chiroptical properties of the ink are adjustable by altering deposition rates, and so the optical properties of the final print can be varied spatially, resulting in spectacular visual effects generated from a single ink, during a single print.”

In other words, they were able to produce a iridescent printable polymer ink whose optical properties could be controlled. They could print polymers with specific polarization and iridescent properties.

If you read their paper, you’ll see that the process to control the properties is quite complex and involves interesting an two-step stereolithography procedure with specific temperatures. They found that print speed has major effects on the visual appearance of the printed material.

While the prints made using this process are quite thin, they are sufficient to be considered for industrial and design applications. For example, it may be possible in the future to include a tooling on a 3D printer equipped to print this iridescent material. Then it would be conceivable to, say, 3D print a robot actuator fitted with a specific type of optical sensor.

This area likely has many potential applications, but it is so new and in an area lacking exploration, it may be some time before we see this technique in commercial use.

Via Wiley