Charles R. Goulding and Arianna Coger examine R&D at CollPlant as bioprinting interest picks up.

CollPlant Biotechnologies’ recent partnership with 3D Systems has sparked a great amount of interest in their potential to produce unique and innovative medical products. The two companies recently announced their agreement to work on the development of bioprinted solutions for improved breast reconstruction procedures.

The CEO of CollPlant, Yehiel Tal, stated, “We’ve joined forces with 3D Systems to offer a regenerative soft tissue matrix that may significantly increase the addressable market for soft tissue reinforcement in breast implant procedures. A regenerative solution can increase safety, eliminate product variability, and enhance results by promoting new tissue growth.”

According to the CDC, breast cancer is the second most common form of cancer in women, with millions diagnosed with it annually. Depending on severity, a mastectomy may be needed to remove the tumor. Many patients consider breast reconstruction after treatment. CollPlant and 3D Systems aim to expand the number of reconstruction options available after a mastectomy.

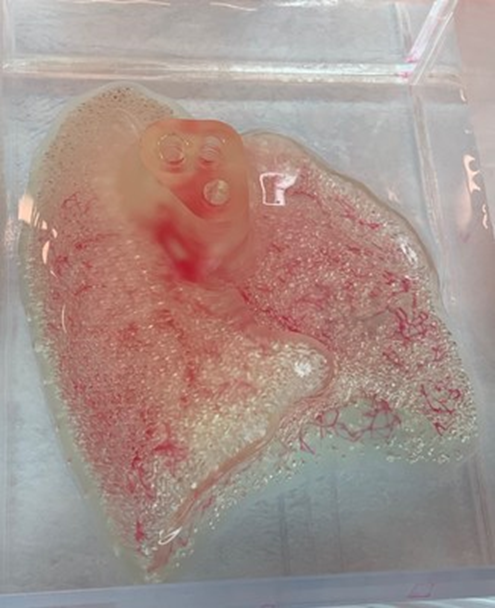

This collaboration is not CollPlant’s first project with 3D printing. The team previously had a partnership with United Therapeutics, a biotech company, to develop formulations for bioprinting scaffolds for lung and kidney transplants. The company has recently appointed Hugh Evans, an additive manufacturing executive, to its Board of Directors.

CollPlant’s chair, Dr. Rojer J. Pomerantz, commented, “Hugh has a deep understanding and appreciation of CollPlant’s technology and how it can be transformative in advancing the 3D bioprinting field. We are very pleased to welcome him to the board and look forward to his guidance and support.”

The company continues to look towards expanding their usage of 3D printing for biomedical applications.

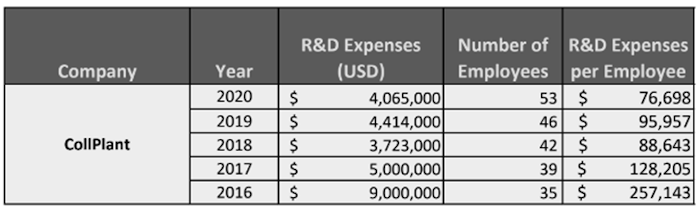

CollPlant Biotechnologies has filed eleven patent families and published twelve peer-reviewed studies since its inception. A large percentage of their funds go towards new research and development.

Many of their patents are related to their recombinant human Type I collagen (rhCollagen) produced through genetically engineered tobacco plants. Unlike other forms of collagen, rhCollagen can be extracted from plants rather than humans or animals. Its plant-based nature allows its conditions to be precisely controlled for homogeneity, improved biofunctionality, and reduced risk of immune response. The table below demonstrates CollPlant’s R&D investments:

The company currently plans to use rhCollagen in all their ventures, including their research on new breast reconstruction techniques. The collaborators aim to develop 3D bioprinted implants using a combination of rhCollagen, autologous fat cells, and extracellular matrix components with hopes that their product will promote tissue regeneration and degrade as the breast tissue naturally develops. Other implants, such as those made of silicone, can have risks associated with them, such as ruptures. The risk of rupture would be eliminated using this technology due to its degradation.

CollPlant and 3D Systems’ stock values surged after their announcement to pursue 3D printed breast tissue solutions. However, it should be noted that CollPlant has yet to perform comprehensive clinical trials with their rhCollagen technology and obtain regulatory approval. Additionally, their ability to manufacture products outside of Israel may be hampered due to restrictions from the Israel Innovation Authority (IIA). It is possible that CollPlant may need approval from the IIA’s committee to expand their production internationally. As a result, it may be more difficult than expected to commercialize their products.

Despite these factors, many investors and collaborating companies still see great potential for advancements in CollPlant’s bioprinting activities.

Federal tax incentives, such as the Research and Development Tax Credit, are available for companies that engage in 3D printing activities.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

Companies continue to steer towards advancing biotechnology with 3D printing. If CollPlant succeeds in their research and the commercialization of their product, they may find new doors opening to collaborate with more companies and expand the usage of rhCollagen for new medical and aesthetic purposes.