[Source: Alteryx]

3D printing technology is evolving so fast that university supply chain programs and manufacturing supply chain departments need to have regular 3D printing continuing education.

Prior Generation 3D Printing Supply Chain Processes

In the mid-2000s, after finishing 30 years of Fortune 500 engineering-based industrial manufacturing, I was able to observe firsthand the function of new supply chain programs. At that time, the goals outlined were cost reduction of existing components with a focus on global supply chain processes.

With the global sourcing programs back then, the activities included auction programs aimed at best price and purchasing criteria which included product cost, shipping costs and customs duties. Risks included quality, supplier working conditions and total time to deliver. At its essence, this was really a consideration of make versus purchase decision analysis. Many leading university supply chain programs were created using these concepts.

A New Generation Supply Chain with 3D Printing

In the last 20 years, 3D printing technology has greatly accelerated and must now be part of supply chain management.

Today’s university supply chain programs should become knowledgeable about their own university’s 3D printing capabilities as well as the programs at other leading universities. At manufacturing companies, supply chain managers should monitor the technology developments in the 3D printing industry.

They can do this by reading leading 3D printing blogs like Fabbaloo. They should continuously monitor developments at leading additive or 3D printing manufacturers including but limited to Stratasys, 3D Systems, HP, Carbon, Desktop Metal, Markforged, ExOne, GE and Siemens. They should also follow the 3D printing achievements at large contract manufacturers such as Jabil.

It is particularly important for supply chain manufacturers to follow developments in 3D printing or additive manufacturing topology. Complex part topologies enable the development of entirely new products that, without 3D printing technologies, could not be manufactured. Advanced topology often results in better components that can materially reduce the number of required components. Knowledge of topology developments can enable supply chain professionals to leapfrog the competition.

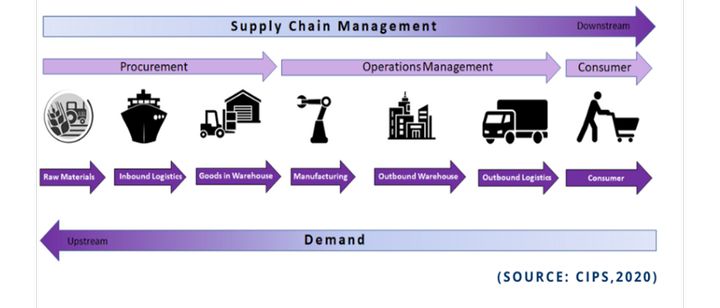

[Source: CIPS]

Conclusion

This is an exciting time for the 3D printing industry, which is undergoing unprecedented levels of innovation. University supply chains and manufacturing supply chain programs can incorporate these developments into next-generation supply chain programs.