MakerGear published a video of an impressive endurance test.

The Ohio-based company is one of the older desktop 3D printer manufacturers, having been founded in 2009. They’re known best for producing highly reliable equipment, and evidently they wanted a visible demonstration of their reliability recently.

MakerGear explained:

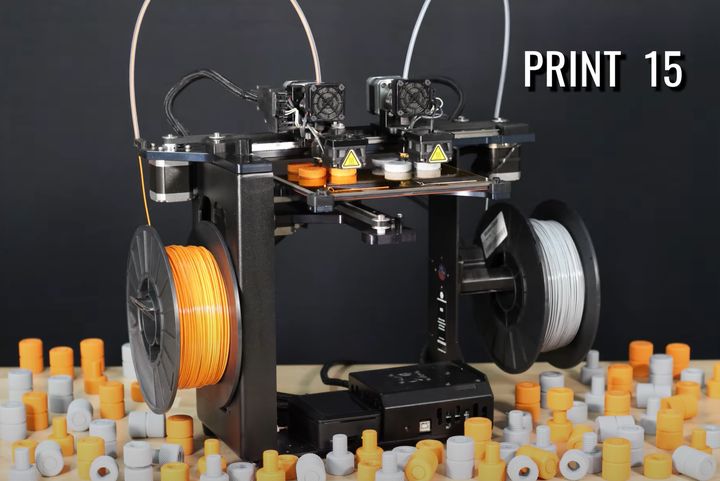

“With so many 3D printer manufacturers all claiming to build ‘the most reliable printers on the market,’ we wanted to find a way to actually prove it. So earlier this month we took a printer from our print farm that already had hundreds of hours of print time and put it to the test. Running print after print after print after print, we collected almost 5000 photos to create an awesome time-lapse for our newest video. We couldn’t have been happier with the results.”

Here’s the short video showing the demonstration:

Sure, the parts are not particularly complex, but they certainly did come out with excellent quality.

The important thing here is that this older machine was perfectly capable of running continuously for a week producing parts. MakerGear said they did not have to relevel the machine once during the week-long experiment, and no prints failed. Additionally, they said all the parts produced were entirely within tolerances.

How do they achieve this? I think there are a couple of reasons.

First, MakerGear is known for making very robust machines with higher-quality components than some competitors. That goes a long way to achieving a long and productive life for any desktop 3D printer.

Secondly, the machine was certainly tuned properly. While 3D printers are notorious for frequent failures, many of those events are directly related to poor setup. For example, if a print surface isn’t quite level, eventually a print’s geometry will fall victim to poor adhesion and the print will fail. By ensuring a machine is carefully calibrated you dramatically reduce the possibility of error.

Finally, MakerGear said this machine was older and well-used, having been in their print farm for some time. If a machine survives that long, it’s likely to be made of very reliable components; lesser machines would have burned out or failed earlier. It’s a bit like evolution: the strongest survive. And that’s what we’re seeing here: a survivor that’s proven to work. If it worked well on the print farm, there’s no reason it could not continue to do so.

While many 3D printers don’t undergo such tremendous workloads, those that require that level of use might consider machine purchases more carefully than others. Units destined for 3D print farms absolutely need to last a very long time to squeeze out as much value as possible, and that’s only achievable with very robust equipment, such as you can find with MakerGear.