In a very surprising announcement, Mosaic Manufacturing announced a series of revolutionary products that will utterly transform the company and its clients.

The Toronto-based company is well-known for their useful line of Palette devices. The Palette concept is ingenious: it interprets incoming GCODE for a 3D printer and literally splices together up to four different filaments to create a “custom filament” for the current print job. This allows almost any FFF single-material 3D printer to immediately become a multi-material device. Typically clients use the Palette for multi-color jobs, although it is also possible to use different material types.

Up to now the company has been building on this concept by announcing incrementally improved versions of the Palette. That’s what you’d expect from a company that’s invested in developing important accessories for 3D printers.

Today they’ve announced some new stuff. They announced:

- The Palette 3

- The Palette 3 Pro

- The Element 3D large-volume 3D printer

- The Element HT high-temperature 3D printer

- The “Array” Robotic multi-printer factory system

- The “Array Production”, a large-scale production 3D printing system

- New Software

- New Materials

What?

I repeat, WHAT?

This relatively small Canadian company, which previously had produced only 3D printer accessories and a line of material,s has suddenly announced large-scale manufacturing equipment. Among the slew of announcements is the Array, which I suspect could be the only high-temperature automated array 3D printing solution on the market.

When I said “transform” above, I was deadly serious.

Mosaic Manufacturing is no longer an accessory maker. They are now on par with other manufacturers of professional and even industrial 3D printing gear.

Let’s take a breath and look briefly at each of the pieces of this stunning announcement.

Palette 3

The Palette 3 is an improved version of their previous devices, as you might expect. The big difference is that they’ve integrated a new “Canvas Hub” into the Palettes and it permits wireless access to the 3D printer, much like a set-top box would enable. That’s very convenient: multi-material AND remote access in one purchase.

Palette 3 Pro

The Palette 3 Pro is similar to the Palette 3, except that it allows for EIGHT filaments instead of “only” four in the base unit. This capability is among the broadest I’ve seen, as most other filament changer systems have 4-6 filaments as their maximum capacity. The Palette 3 devices can be pre-ordered now at a discount price of US$499 & US$699, but will eventually rise to the retail price of US$599 & US$799.

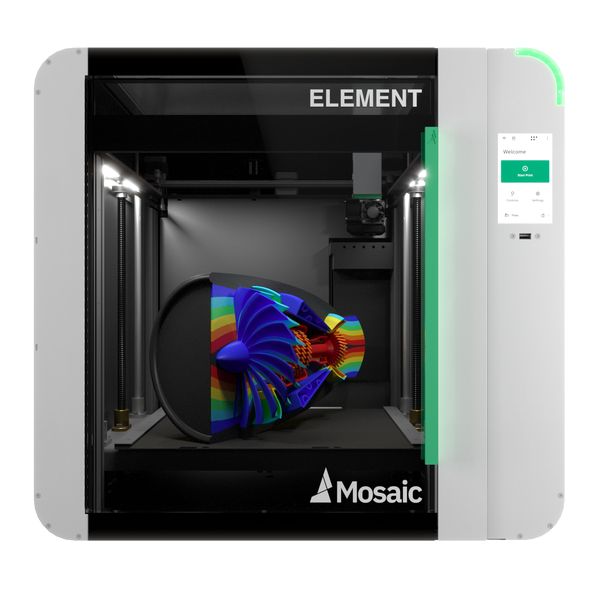

Element 3D Printer

The Element is Mosaic Manufacturing’s first 3D printer, and that alone is quite a surprise. However, the Element has some interesting capabilities. First, its build volume is enormous at 355 x 355 x 355 mm, much larger than most desktop 3D printers. Secondly, the Element has a built-in Palette “X” unit, which is essentially the same as the Palette 3 Pro. In other words, the Element is a multi-material (eight) 3D printer, without the need for an accessory.

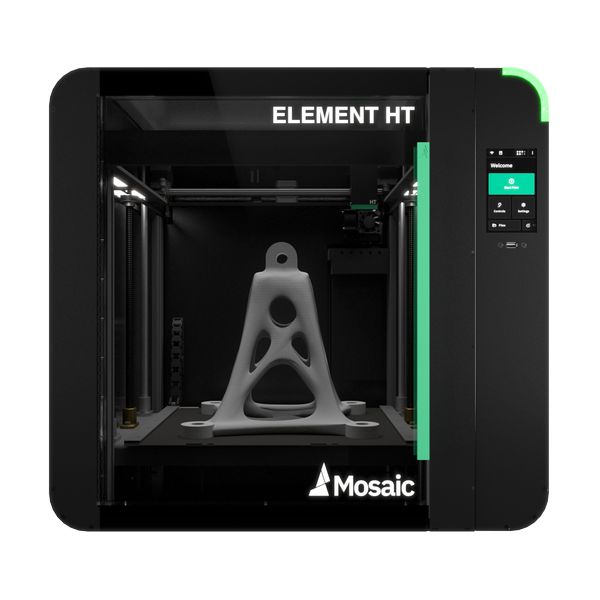

Element HT 3D Printer

The Element HT is similar to the base Element unit, but is a high-temperature device! Element HT includes a heated platform up to 120C, an actively heated build chamber to 80C, and a hot end that can reach 500C. This means the Element HT is fully capable of 3D printing exotic engineering materials such as PEEK or ULTEM. The Element 3D printers will ship in late 2021 at a cost of US$5,999 and US$9,999.

Mosaic Array

The “Array” is Mosaic Manufacturing’s method of parallel 3D printing with an array of Element 3D printers. It contains four Element HT 3D printers, and is fully automated.

The automation is a robotic system that will remove completed print plates from the Elements and place them in a moveable cart much like a cafeteria tray. It then sets up fresh plates for new print jobs. When you combine the embedded Palette X, this means there is the possibility of running jobs nearly continuously for very long periods: there is little need for operators to swap print plates or load new spools of filament. Remember, the Palette X can access EIGHT spools.

The Array system includes not only an easy-to-use touchscreen, but you can also operate the device remotely using an app.

The Array will sell for US$59,999 and is expected to ship before the end of 2021.

Mosaic Array Production

The Array Production seems to be similar to the Array, except for one thing: it includes TWENTY-FOUR 3D printers instead of four, and six carts for completed print jobs. It’s targeted for mid-volume production. Mosaic Manufacturing expects to release this machine very late in 2022.

Filament is stored inside the array at the rear in cartridges, where spools remain within a controlled atmosphere. This will increase print quality and reliability, as well as enable pre-heating of spools.

Mosaic Manufacturing says the Array can operate unattended for at least 72 hours, and perhaps ays longer depending on the nature of the specific jobs involved.

I’ve learned a lot more about the intriguing Array system, but that will be told in another post.