DNV announced new service specifications for use of additive manufacturing in the energy sector.

DNV is a global risk-management company. They provide analysis and insights to allow clients to both understand and manage their risk portfolios. DNV says they are the “world’s leading classification society” for maritime operations, and they also serve the energy sector.

Part of their work is to provide benchmarks for various aspects of industry activity, and that includes the manufacturing of parts used in operational processes. They explain the new specification:

“DNV has released a new service specification document with the aim to support stakeholders across the Additive manufacturing (AM) value chain to ensure AM products, assets, and systems are safe and efficient. The specification can support the global oil and gas and other energy industries to adopt AM technology for gaining cost and efficiency benefits while maintaining safety.”

The new specification is DNVGL-SE-0568, and it is a specification that fits on top of DNV’s earlier AM specification, DNVGL-ST-B203. “B203” covers these aspects:

- The qualification of parts made by additive manufacturing (AM) for the oil and gas and related industries

- The purchasing of AM parts

- Quality management for manufacturers of AM parts

- The manufacturing of AM parts

As you can see, this older specification covers the technical parts of the production process, focusing on the parts themselves. That’s where the new specification comes in, because it covers all the other related aspects of the production of oil and gas parts by additive processes.

DNVGL-SE-0568 covers these additional aspects:

- Endorsement of facilities and digital products/services

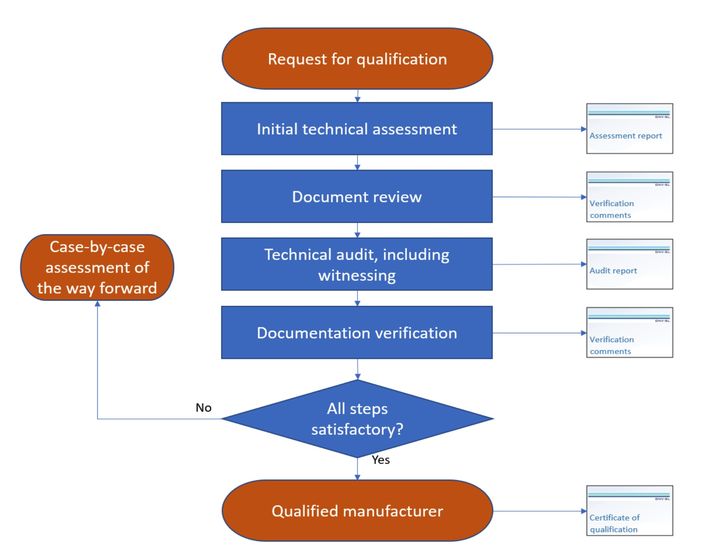

- Qualification of manufacturers

- Qualification of build processes

- Qualification of parts and part families

- Qualification of AM machine(s) and equipment

- Qualification of AM supply chain service providers

- Qualification of AM personnel

The new specification covers a far broader spectrum of related activities, even including qualification of staff. It also defines the process of the audit required to achieve certification for the standard.

For personnel qualification, the standard says:

“Material specialists and surveyors shall be competent within the topics given in DNVGL-ST-B203. In addition, they shall be qualified in accordance with DNV GL’s competence schemes. A list of qualified material specialists will be made available to the customer on request.”

If this sounds like a lot of work to become certified, you’re probably correct. However, obtaining these certifications can be quite important, particularly when you look at insurance requirements.

For an oil and gas operation, insurance is quite important because of the potential impact should something bad happen. However, bad things can happen if parts suddenly fail while in operation. That’s the goal of the DNV standards: make sure the parts used are most likely at the necessary levels of quality, thus lowering the possibility of a problem.

When dealing with insurance for such operations, it would obviously be critical to be able to present these certifications, as the insurance quotes could be quite a bit lower. Imagine buying insurance without certifications, and you can quickly understand the issue.

From a larger point of view, DNV is one of many producers of a broader set of emerging standards for additive manufacturing. These standards are all necessary if AM is to truly take a piece of of the world’s manufacturing operations.

Via DNV (Hat tip to Benjamin)