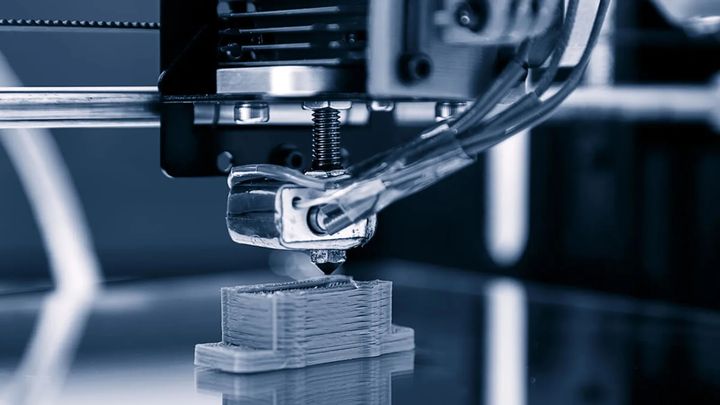

In a world of digitally driven production, additive manufacturing (AM) has steadily solidified its place as a vital component to enhance nearly every aspect of the manufacturing process, albeit if the right technology and budget are available.

As new technologies push AM further into mainstream use, the implications of its use could be far-reaching.

In a recent in-depth research brief from MIT, a team delved into what those implications might be. From a changing workforce—which has seen a rising skills gap that shows no signs of slowing down—to the ability to adopt AM and boost a company’s competitiveness, the technology has the potential to streamline operational advances across the manufacturing sector.

Consumer-Driven Design and Performance

AM has long been a go-to technology as a faster, more cost-effective solution for prototypes. Whether for a small, intricate part or a large-scale metal component that would require weeks to create, AM has proven to be a beneficial tool in advancing research and development to the next level. Along with the benefits of rapid prototyping, new innovations are making serial and customized production possible.

For industries such as health care and retail, a manufacturer’s ability to produce customized 3D-printed products has the potential for a manufacturing revolution that consumers could greatly benefit from. AM allows for the creation of durable, quality products and a geometric freedom that is much more possible than ever before. From mass-producing custom hearing aids with the electrics included to using lightweight materials to tailor shoes to an individual’s unique feet, precedents are being set that are turning how things are made on its end.

Customizable 3D-printed products are also coming in the form of bicycles, jewelry, furniture, eyeglasses, and much more. Even if the technology isn’t used for the products themselves, AM is a growing trend in packaging. When a brand wants to stand out without having to somehow meet at an outrageous budget, technology provides for a unique design that allows for adding built-in tracking and other logistical components to make the sales and shipping processes easier.

Increased Operational Efficiencies

In many industries, dealing with big, heavy parts and materials is cumbersome and comes at a higher price. What if a company could reduce product development and production time while reducing the cost and weight? Luckily, many can now do that. AM not only provides designers and engineers with an easier way to test new materials and designs and to get a hands-on feel for the design, it also makes it much easier to incorporate changes.

The added flexibility and reduction in lead time that AM provides especially garnered it praise throughout the pandemic. From makeshift face masks to the creation of essential parts for needed medical equipment, going from design to a working product happened quickly and efficiently. It also eliminated worry about stalls in the supply chain for needed materials.

Read more at ENGINEERING.com