A comprehensive survey performed by industry analysts Gartner have identified the key barrier to investment in 3D printing technology by companies: Cost.

The survey found most respondents (approximately 60 percent) indicated they delayed their purchase of 3D printing equipment due to the high costs of setting up operations.

We’re not surprised, as the costs of industrial 3D printing gear can be spectacularly high. But that’s not the only cost involved, as you need more than just equipment to truly do 3D printing. Here are some of the other major cost components:

- Materials. Industrial 3D printers often require very specific, proprietary and expensive materials, be they plastic, resin or metal.

- Software. 3D design software for industry can also be expensive, with some toolsets exceeding USD$10,000 per seat.

- Training. If your company does not currently have capable 3D modelers, there’s a lengthy process to get designers up to speed on the software. Either that or you’re undergoing a hiring process that can be equally expensive and time consuming.

- Workflow. The presence of 3DP equipment implies changes to industrial workflows, which can be expensive to deploy.

- Environment. Industrial 3D printers sometimes require peculiar environmental conditions, sometimes necessitating construction, electrical, HVAC and other expenses – and corresponding delays.

And even if you do all that, you still won’t see the true benefits of 3D printing unless your designers are sufficiently creative to produce designs that actually leverage the capabilities of 3D printing technology. You shouldn’t simply 3D print the same parts you’ve always made; 3D printing enables radically new designs that can simplify workflows, assemblies, weight and often costs.

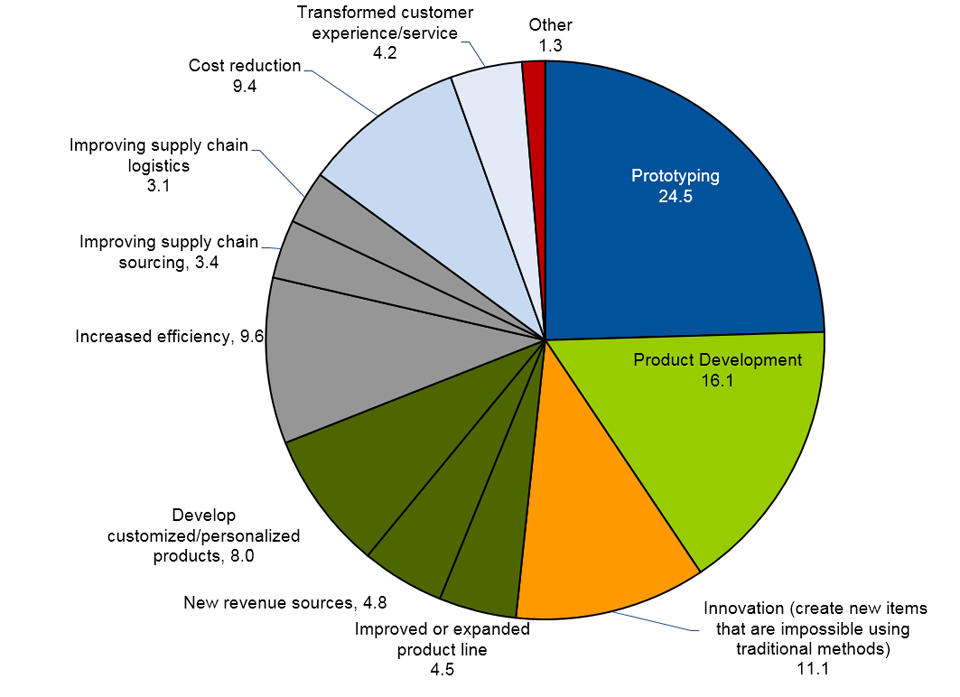

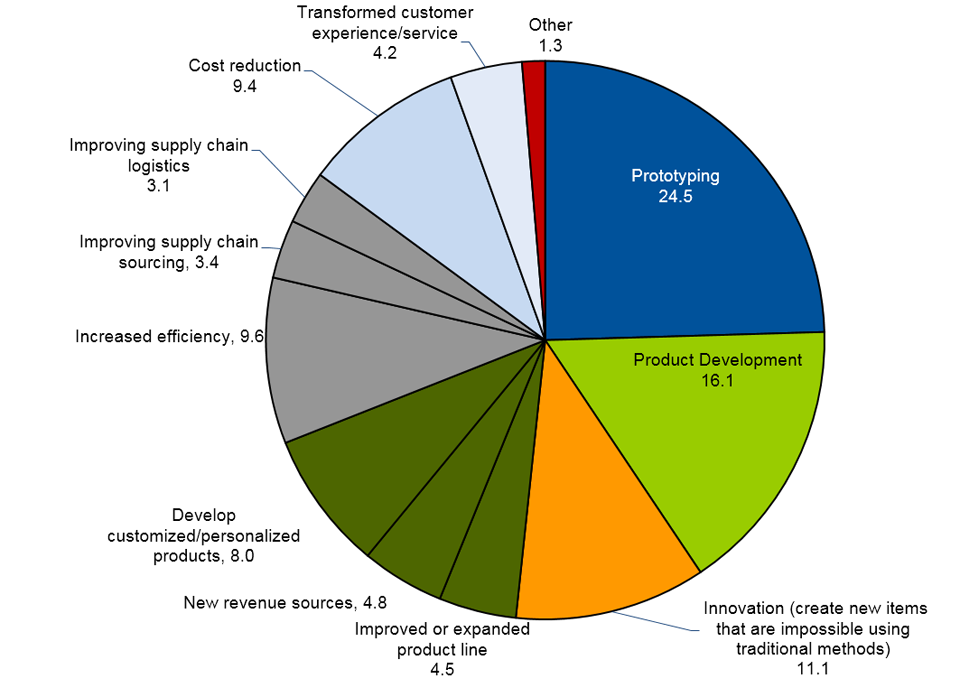

In fact, the Gartner survey revealed that only 11.1% of respondents use 3D printing for “lnnovation (create new items that are impossible using traditional methods)”. There’s plenty of room for improvement.

Via Gartner