Having written a couple of stories focusing on belt 3D printers recently, I have some thoughts about their future.

Belt 3D Printing

For those unaware, belt 3D printing is the concept where the print plate is replaced with a moving conveyor belt. The 3D print takes place at a 45-degree angle, allowing for near-continuous 3D printing as the belt slowly shifts the print.

Thus with belt 3D printing you can produce very long objects, far larger than the 3D printer itself — so long as you find a way to support the 3D print as it emerges. Sometimes this property is called “infinite” 3D printing. Alternatively, you can 3D print a series of small objects repeatedly. They will automatically peel off the print belt as it turns around at the end of the printer, and the completed prints fall into a collection bucket.

Belt 3D Printing History

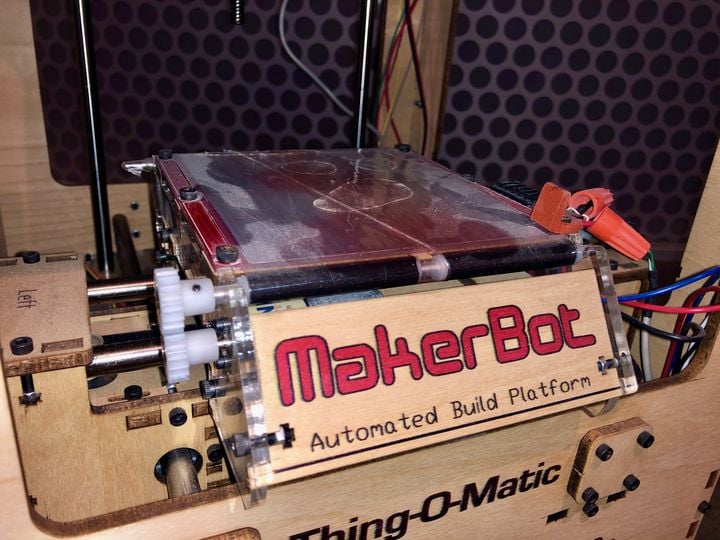

The first belt-style 3D printer was developed by NYC-based Charles Pax in the 2010 timeframe. It was a motorized belt that fit around the MakerBot CupCake heated platform. I actually have a MakerBot Automated Build Platform, and it worked quite well — until the belt warped due to repeated heat exposure. But up until then I was able to print off dozens, maybe hundreds, of small items with almost no intervention required. It transformed my otherwise modest CupCake 3D printer into a kind of “factory”, able to produce many objects on request.

While Pax initially worked on this concept independently, it seems that he completed the work while working for MakerBot “full time”. In a post dated Sept 13, 2010, he says:

“We’ve launched the MakerBot Automated Build Platform! I’m endlessly happy about this. I’ve hacked on this for the past year. I began full time work about two months ago when I started working at MakerBot Industries.”

This product was subsequently patented by MakerBot, much to the consternation of the MakerBot community, which at the time believed the company to be “true to open source principles” and felt betrayed. However, shortly thereafter MakerBot was forced to switch gears and focus on industrial markets due to investor pressure. This episode in particular generated bad press for the company in the open source community that persists to this day.

The patent in question is US8226395B2, which is assigned to MakerBot, and lists the inventors as “Charles E. Pax, Zach Smith, Adam Mayer, Nathaniel B. Pettis”. Pax appears for obvious reasons, while Mayer and Smith were among the founders of MakerBot. “Nathaniel B. Pettis” is none other than Bre Pettis, the well-known former CEO of MakerBot. US8226395B2 expires in 2030.

But here’s the thing: this patent describes a process in which only the build plate is different. The hot end system remains as it exists on virtually all FFF 3D printers to this day: vertically oriented. Thus it is only useful for unloading a print job, not for infinite 3D printing.

After the MakerBot ABP faded away, we heard little on this concept until only a couple of years ago.

Modern Belt 3D Printing

Stratasys, the owners of MakerBot, showed off a “continuous 3D printing demonstrator” a few years ago. It was perhaps the ultimate application of Pax’s original concept, as they deployed an array of basic 3D printers that printed on rolls of plastic. These would be cut off and dropped in a bin for sorting, and provided a means for continuous (but not infinite) 3D printing.

Strangely, after that public demonstration in 2017 no one has heard about this concept from Stratasys.

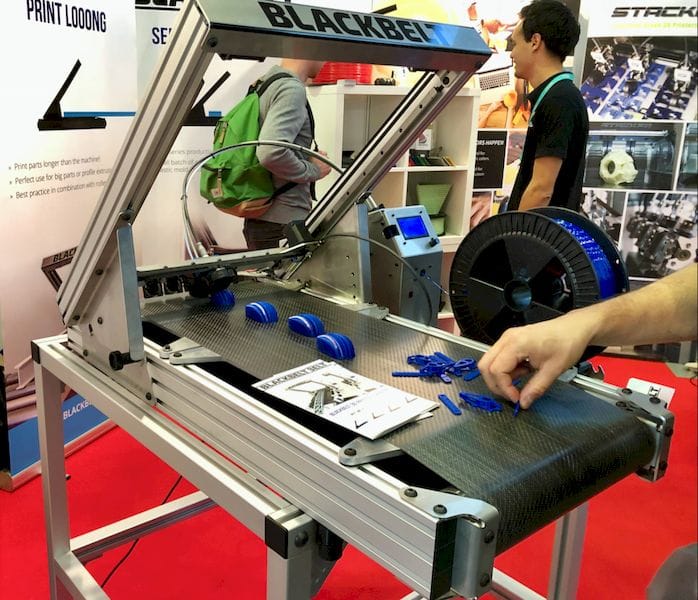

Things changed when a Netherlands startup, Blackbelt 3D, announced a revolutionary new approach. In addition to using a belt build platform, the Blackbelt approach involved 3D printing at a 45-degree angle. This allowed for the continuous 3D printing described above, and is in fact quite different from the MakerBot patent: there are different purposes for the two approaches. Pax’s is for removal of prints, while the Blackbelt approach also allows for “infinite” 3D printing.

It was a fantastic concept, but did not immediately catch on, perhaps due to the rather high price of the Blackbelt device and insufficient marketing.

A few other belt 3D printing projects emerged, such as Robotfactory’s SilverBelt, the White Knight from NAK3D, and the PowerBelt3D Zero. But none of these “took off” in the market.

Belt 3D Printing in 2020

Then in the past few months two key things happened.

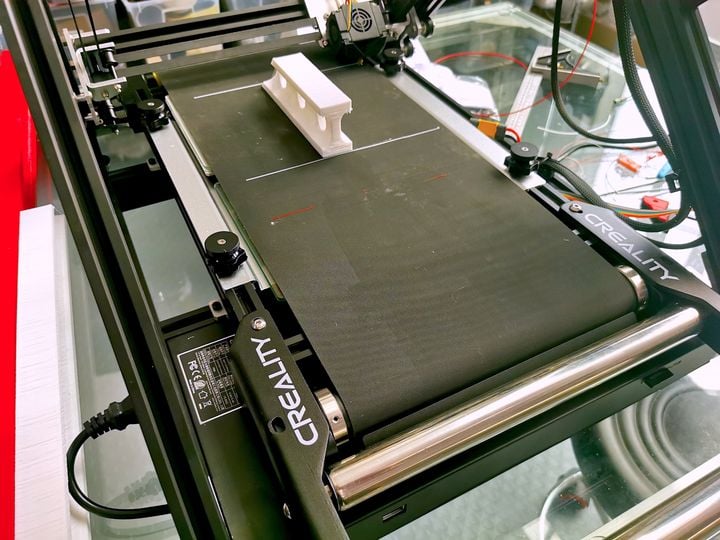

First, Creality announced they are developing a belt 3D printer that is set to be released in November [see image at top]. It seems to be a project based on the White Knight design, and coordinated by supermaker Naomi Wu, whom we interviewed about the CR-30 belt 3D printer recently.

Having seen a distinct lack of interest in the market for belt 3D printers over the years, and reading some comments on our story, it seemed clear many people continue to see no use for such a device. Some of the comments I’ve read include:

“I really don’t understand the appeal of this sort of machine.”

“If I’m printing a bunch of small objects, I’d rather fill a build tray with them, and then swap it out every 8 hours when it’s done.”

”The long objects idea neglects basic physics – unless the part hanging off the side is very light, at certain point it is going to drop down and peel the other side from the belt, ruining the print.”

”As someone who is quite deep into this as hobby I have to agree. ‘endless’ printing is a niche feature that would barely see any use.”

“It seems like an engineering mistake to have the nozzle canted in relation to the bed.”

“I’m still not getting it. What’s the harm in printing at the normal angle and moving the belt as needed?”

That last point is, I think, the issue here. People simply don’t understand what these devices could do, and indeed some of the commenters did not truly understand the current state of 3D printing, dismissing the concept as if it was being proposed ten years ago.

Meanwhile, Wu told us she’s heard nothing but excitement for the upcoming Creality CR-30 / 3DPrintMill, but that is likely because only those interested are contacting her.

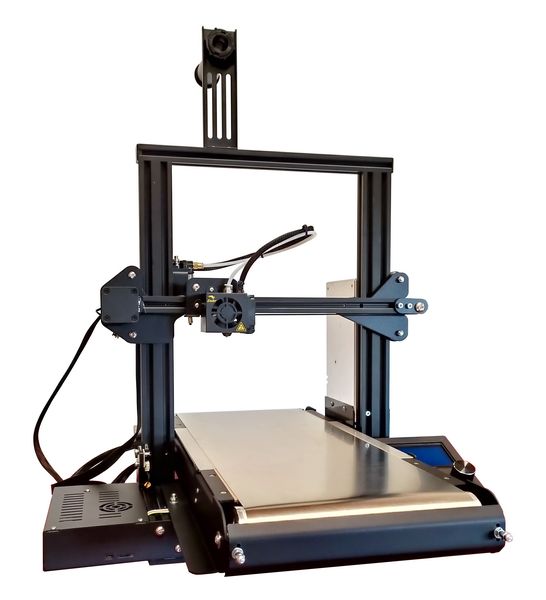

The second bit of news is that Robotfactory has suddenly announced a conversion kit that will allow almost anyone with a basic 3D printer to convert it into a belt 3D printer. This, if priced correctly, will allow thousands of individuals to directly experience belt 3D printing, in addition to those using the Creality machine.

They will all understand the power that is unleashed with a belt system.

They will tell everyone. And soon, everyone will understand.

Future of Belt 3D Printing

To me, a belt 3D printer almost represents a different class of device. Instead of an amazing machine that can produce an object out of thin air, it becomes quite literally a factory on a desktop, able to produce small volumes of objects at the touch of a button.

This is very, very different from the experience of repeatedly unloading a 3D printer and re-running a job. It’s more like magic: just pick up your bucket of parts later, and it couldn’t be easier.

When these machines become more popular we will see small-scale manufacturing take place in many places. Sure, the parts will not be as good as injection molded parts, but parts of that quality are certainly useful for all kinds of applications. That’s the same equation as happens in normal 3D printing today.

Once that “factory” business model is established, it won’t take much longer for larger-scale and even industrial versions of the belt concept to be developed. Perhaps we’ll see devices that automatically unload completed prints into post-processing equipment, fully completing the production process.

You may scoff at belt 3D printers today, but I think you may own one in the future.