Charles R. Goulding and Peter Favata explore the use of 3D printing in the world of golf.

Golf was invented in 15th century Scotland, making it one of the longest-running active sports in history. Participation in golf has been on the rise as of late with a total reach of over 108 million people a year in the sport. In the times of COVID-19 people are also looking for new low-risk activities and golf has been named the second safest sport to partake in. This has led to a new wave of golfers who are just starting to pick up the sport. Some pick it up because they enjoy the beautiful scenery while hiking through green tree-covered landscapes, others just want to go out with a group of friends and play competitively. Either way, there are more people playing golf now than before.

Innovation in Golf

Golf has been one sport that is always coming out with new equipment to increase the level of play from the beginner level up to the PGA and European tours.

The golf ball is a great example of this. Originally the ball was known as the “featherie” and was made with leather so it would work well if gotten wet. They would then pack the ball very tightly with wet feathers that would expand when dried, creating a very hard ball. The golf ball went through many different variations until it became the ball people know today.

3D Printing Playing a Role

Continuing on the tradition of innovation 3D printing is starting to play a role in the golf world. For some time now people have been using 3D printers to make some accessories such as divot tools and tees allowing endless customization possibilities. Newer devices such as target practice accessories have also emerged, as well as use of 3D printing to restore historical golf clubs.

In June of 2020, Cobra Golf, who sponsors pros such as Rickie Fowler and Bryson DeChambeau just to name a few, signed a deal with HP Inc. to work on 3D printing some of their new products. Cobra plans to use HP’s Metal Jet 3D printer to produce new clubs and accessories to bring to market while cutting costs due to supply chain interruptions. This partnership will also allow more freedom and faster turnover when it comes to design iterations that will provide Cobra with the data to produce the best clubs possible. Cobra has experimented with 3D printing in the past for designing prototypes of their clubs using CAD software and printing them to run processes like aerodynamic tests.

Golf Push Carts

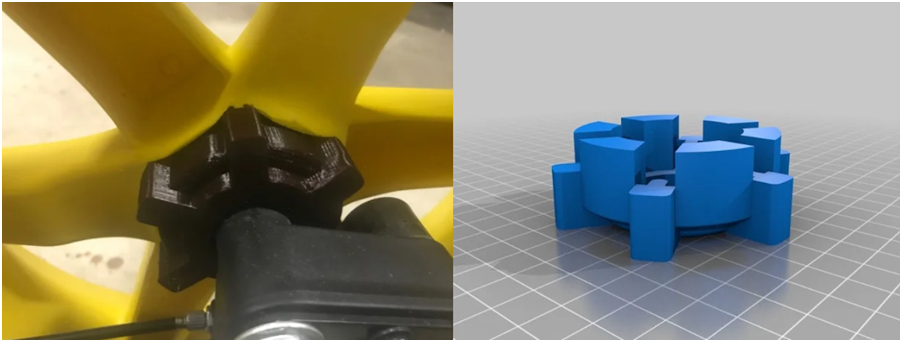

Another area where 3D printing can be utilized is with push carts. The primary design of these carts is a two- or three-wheeled unit that is most of the time collapsible and made out of plastics that can be 3D printed. If producers decided to start 3D printing push carts they could allow for more customization and lower prices for the products. People have already started using 3D printers to create replacement parts and accessories for their carts.

One Thingiverse maker has developed a replacement brake gear for a Clicgear push cart, which underwent several versions and testing until the design produced adequate strength to last at least two golf seasons. Another maker on Thingiverse has recently designed a beverage holder that can be attached to a golf push cart, allowing the user to be more easily hands free.

Manufactures and designers utilizing 3D printing in the golf industry may be eligible for R&D Tax Credits.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit can be used to offset Alternative Minimum Tax (AMT) or companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in cash rebates that can be applied directly to payroll taxes.

Conclusion

Golf producers have always been searching for ways to make new products while finding the perfect balance between performance and style. With the increase in golf’s popularity there are going to be many different types of golfers this includes a younger group. This younger crowd wants their equipment to look good as well as perform. 3D printing could also bring customization options to please everyone on the course. Either way, there is never a bad day out on the course.