Researchers have developed a way to fabricate microscopic endoscopes using 3D printing technology.

Endoscopes are those devices placed on the end of a catheter and inserted into a patient. They are typically used to image the internals of a body, as that can reveal information not available unless surgery is performed. In other words, endoscopy is a fantastically faster, cheaper and safer way to get inside the body.

Endoscope Diameters

However, there’s been a problem: the size of the endoscope limits the possible areas of exploration. If the diameter of the endoscope is larger than the area to be explored, it won’t work. This gets even more complex when, for example, the endoscope is in a critical position like an active blood vessel. An endoscope of sufficient diameter could literally cut off the blood flow in a kind of artificial heart attack.

There’s also the possibility of larger probes causing damage by simply bumping and squeezing their way through delicate tissue.

Thus there’s been a quest to produce ever-smaller endoscopes. But the limits of traditional fabrication have dictated the end of the line.

At least until now.

3D Printed Micro-Endoscope

The team of researchers from Australia and Germany were able to 3D print an extremely tiny endoscope assembly using a “novel ultrathin probe fabrication technique that utilizes 3D microprinting”.

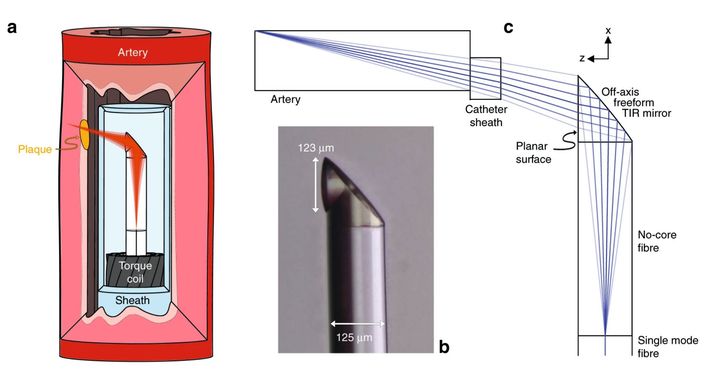

The issue here is actually one of optics: the business part of the endoscope is a light collection device, and thus must be of sufficient optical quality to allow for images to be captured. The researchers were able to produce a side-facing micro-optical system with less than 0.130mm diameter.

The resulting freeform 3D imaging probe had a diameter of only 0.457mm, and that includes the sheath used with the attached catheter. While there apparently have been endoscopes with diameters close to this, their optical elements were unable to produce useful images. This was caused by limits to the fabrication of small lensing systems. The researchers explain the issue:

“Current probe fabrication techniques are limited when used for highly miniaturized probes, resulting in spherical aberration, low resolution, or a shallow depth of focus. In optical design, there is a traditional trade-off of high resolution (large numerical aperture, NA), resulting in a rapidly diverging light beam with a small depth of focus and poor resolution (small NA) used to achieve a large depth of focus. Good designs have been attempted to find the optimal compromise between sufficient resolution and depth of focus. Unfortunately, with miniaturized probes, the physical aperture of the probe is very small, and no appropriate compromise may exist. The small scale of the optics also makes it very challenging to correct for spherical aberration, which can further degrade the resolution and depth of focus10. Usually, the correction of the spherical aberration of a single lens is only possible by using an aspherical lens profile (described by a polynomial instead of a circle equation). This shape, however, is difficult to realize on a fiber tip where lenses are often made using a melting process (e.g., creating a spherical ball lens with a profile described by a circle equation).”

But those seem to have been overcome with this new development.

Unbelievably, they were able to use this slender micro-endoscope to probe mouse arteries, which are certainly of very small size. They explain their achievement:

“The utility of the ultrathin endoscope is demonstrated on both in situ preclinical (mouse) and ex vivo clinical (human) models of cardiovascular disease. We are now able to reveal details of the tissue microarchitecture at depths not previously achieved with such small imaging probes. To the best of our knowledge, this is the smallest aberration-corrected intravascular probe to have been developed.”

Nanoscribe Micro-3D Printing

The micro-endoscope was developed using several different technologies, including microscopes, splicers, glass processors and Nanoscribe’s two-photon 3D printing system, which is certainly capable of producing lenses of this size.

What’s really interesting about this experimental probe is that it is 3D capable: the imaging sensor can apparently be rotated during operation, which allows for a full capture of information.

“This 3D printing technology for aberration-corrected imaging endoscopes may make it possible to realize multiphoton imaging inside small luminal organs, allowing for subcellular resolution and molecular specificity deep inside the body,” the researchers report.

This is an incredible development that once again shows how 3D printing technology can be leveraged to open up entirely new areas of application.

Via Nature Light Science & Applications (Hat tip to Benjamin)