There is now another form of manufacturing becoming available: mass customization. But will it become ubiquitous?

For millennia manufacturing was done by hand. Every item was literally hand made. But in the Industrial Revolution things began to change. Increasingly complex machines were applied to the task of making things, eventually culminating in the mass manufacturing infrastructure over the past century.

Mass manufacturing revolutionized the world. Not only was it possible to create many more products efficiently at faster rates and with less cost, but the products became standardized. Bolts and nuts were interchangeable. Machines and products had identical performance and the public gained an expectation of same.

This scenario has persisted for decades, but with the increasing access to 3D printing, things might change.

3D printing offers the possibility of a different kind of manufacturing: mass customization.

Traditional mass manufacturing involves two stages. First, before actual production occurs, “tooling” must be set up. This is the creation of molds, jigs, fixtures and other custom machinery that actually makes the products. Once set up, that machinery is put in motion to manufacture items at high speed and low cost.

The first stage often acts as a barrier, financially, to production.

This is because the cost of setup must be spread across all the manufactured items. Thus, it’s more economical to produce a lot of items than fewer, as the unit cost of fewer items would be higher than otherwise.

This effectively sets a hurdle – the number of items – that a product must meet before being able to manufacture them, as the unit cost must be affordable to buyers. Low volume manufacturing has been problematic because of this.

However, 3D printing offers an alternative, because the technology is able to produce a component WITHOUT the first stage entirely! There is no expensive “tooling” stage, as you simply 3D print the object, so long as you have the appropriate 3D model.

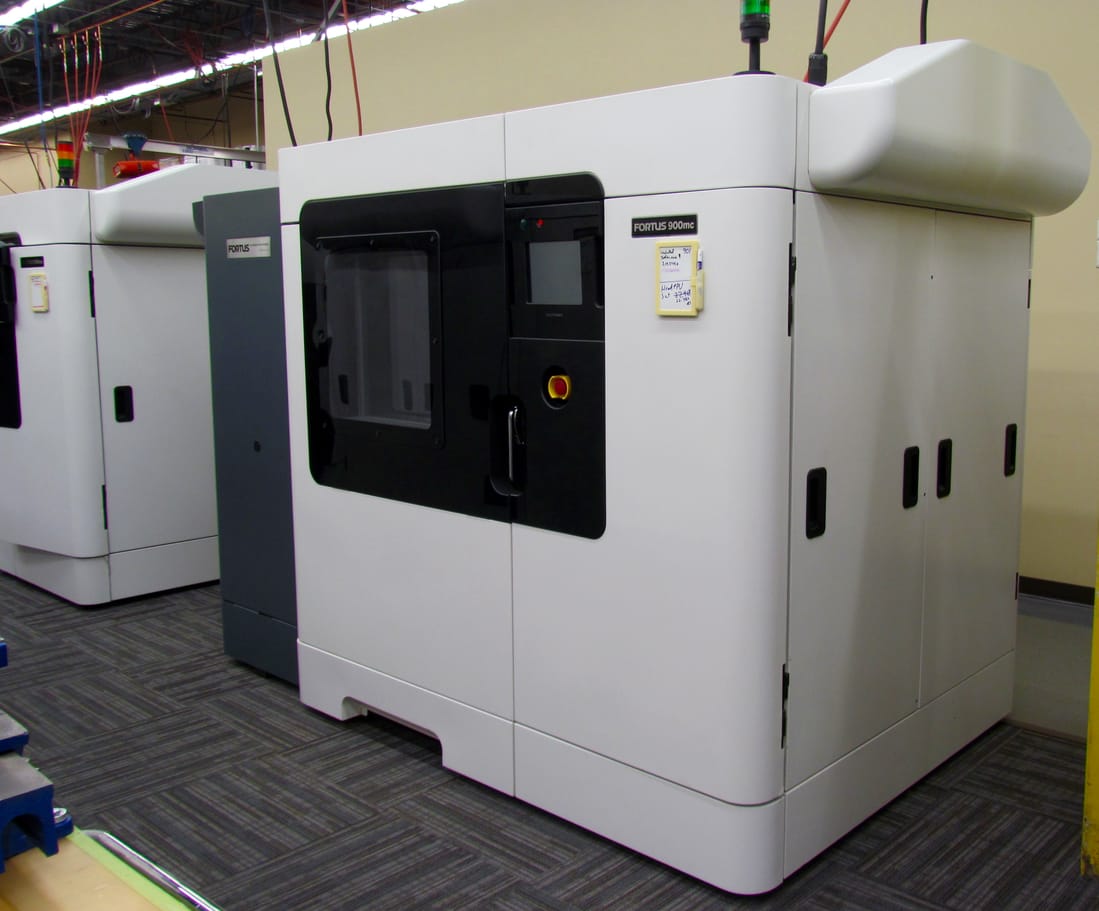

Some have realized this and set up lines of 3D printers for low volume manufacturing services. An array of 3D printers can produce smaller quantities of items without the startup cost, but at a somewhat higher unit cost than mass manufacturing techniques could manage at scale.

Soon this approach will become more common, and it could be that low volumes of products are routinely manufactured in this way.

There’s a twist, though. If the 3D models sent to the array of 3D printers were different or even unique, then different objects could be manufactured at the same unit costs. In theory one could manufacture a customized object for each request with no difference in cost.

This “mass customization” approach is quite intriguing, and some are attempting to determine how it could be leveraged into larger business operations. Applications such as personalized eyeglass frames, shoes or other fashions are potential targets.

But could this flexible mass customization technique become widespread? Could it overtake mass manufacturing in the distant future? Would we see today’s factories transform into mass customization operations?

I don’t think this will happen.

There’s a simple reason for it: some items are meant to be identical, with no reason for customization.

We’ve come to accept, as a society, that many products have an expectation of performance and quality that does not vary from instance to instance. When you buy a Big Mac in a distant location, you expect it to be the same. When you buy a Toyota, you expect it to look the same as the intended design. You expect parts to fit together. You expect

Sure, there are some who might wish occasional minor variances for uniqueness, but by and large there is a tremendous need for standardized products and components.

And what is the best, most efficient way to make lots of identical products? Traditional mass manufacturing, of course.

Thus I cannot see 3D printing displacing mass manufacturing anytime soon. The only possibility that may change that hypothesis is if a sudden discovery changes the financial equation. If 3D printing were to become a lot less expensive per unit, then perhaps more would consider shifting capabilities. But that’s unlikely to occur.

The future looks to include two styles of manufacturing: mass and custom.

Get used to it.