Stacker announced the F1, a desktop 3D printer that is quite a bit smaller than their previous models.

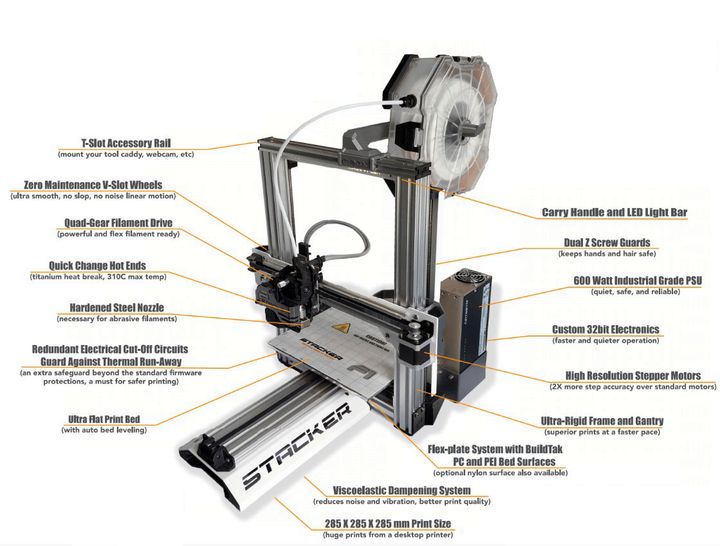

The company intends on launching the device via Kickstarter in July, but has posted a teaser image on their website that shows many of the F1’s key features.

Stacker’s previous machines have several common properties, including large build volumes, multiple extruders and robustly built for industrial use. The F1 seems to inherit some of those characteristics, but it’s really quite a different machine from previous S2, S4 and S4-XL devices.

Stacker F1 Specifications

The F1 is a filament-based 3D printer that has a single extruder, unlike its siblings. However, the titanium heat break should allow extrusion temperatures of up to 310C, far higher than most desktop units. The extrusion system also sports a hardened steel nozzle, which should allow for abrasive materials like metal or glass-infused filament. However, it may still eventually wear out when exposed to carbon fiber-infused materials.

The S2 and S4 Stacker machines are multimaterial, as they include, respectively, two and four independent extruders that can operate together on a multimaterial print or print two (or four) objects simultaneously. There no need to change extruders for different materials because you have them at the ready with the two (or four) extruders on these machines.

This is not the case on the F1, which has only a single extruder. However, Stacker says this system includes “quick change hot ends”. This suggests one could swap nozzles to, for example, go to a larger or smaller extrusion diameter for higher-speed or finer-detailed prints, respectively.

The F1’s motion system appears as robust as its larger siblings, having features such as:

- No-noise linear motion v-slot wheels

- “Quad-gear” filament system for both rigid and flex materials

- “High resolution stepper motors”, with “2X” accuracy

- “Ultra rigid frame”

- “Viscoelastic dampening system” to decrease vibration and noise

The print volume is 285 x 285 x 285 mm, sufficient to 3D print most objects. The print surface itself is a removable spring steel plate with adhesive coating (BuildTak), as is increasingly seen on many 3D printers. Stacker says they have plates with PEI, PC and Nylon available.

If you’re wondering how quickly this print surface would heat up when starting a print, there should be few concerns as the F1 includes a massive 600W “industrial grade” power supply. They don’t state heat times for the F1, but I suspect they are pretty quick.

Note in the image at top the filament is stored in an optional dry box, which Stacker calls the “F-Box”; it’s sold separately from the F1, and can handle spools up to 1kg weight.

Stacker F1 Availability

The F1 isn’t available now, but Stacker says it will launch in July on Kickstarter.

They say the MSRP is US$2,995, but it’s possible they may have a discount for early bird Kickstarter backers as most launches have in the past. We’ll find out when the campaign appears.

Stacker F1 Strategy

While the F1 seems to be a very robust desktop machine capable of 3D printing many different materials, its inclusion in Stackers lineup seems a bit odd. The company had been strongly pursuing the industrial market, hence their robust, multi-part capable previous machines. The F1 seems to diverge from that path somewhat. This is likely why they named it the “F-Series” instead of it being part of their earlier “S-Series”.

Is Stacker changing their strategy? I think they are not, and here’s my theory: their existing clients may have been asking for a smaller machine on which to develop prototypes that would later be produced in quantity on the larger Stacker devices. These lower-priced units could be placed directly beside designers for more rapid turnaround of design iterations.

In any case, the F1 looks like a very robust machine that any professional 3D printer operator could use.

Via Stacker