![Large format printer spare parts printed on demand reducing excess inventory and transport emissions. [Image: HP Inc.]](https://fabbaloo.com/wp-content/uploads/2020/05/Largeformatprintersparepartsprintedondemandreducingexcessinventoryandtransportemissions1_img_5eb098ce13a07.jpg)

Earth Day presents a moment in time for reflection, to take a deeper look at how we are treating the planet and what sort of changes we want to make to better preserve our resources for future generations.

There are many challenges facing our world, from the rise of climate change to the surge in our global population. According to the United Nations, we’re well on the way to a population of almost 9 billion people by 2030, including a growing middle class consumer base. Yet the amount of resources we have at our disposal are fixed, and if we continue on this trajectory we’ll need 2.3 Earths by 2050.

While our world continues to evolve at a seemingly unstoppable rate, what gives me peace of mind is the promise of technology to play a stronger role in the fight for sustainability. One of the most meaningful ways that I see to make a positive impact on the planet is to harness the transformative nature of Industry 4.0. This digital revolution of our global society and economy means that disruptive technologies like Artificial Intelligence, the Internet of Things, and 3D printing can be unleashed to bring about some of the most significant contributions of our lifetime.

Traditional manufacturing processes were designed with little thought to the environment. As industrial 3D production intersects with manufacturing for example, the impact on the planet could be immense as nearly one-third of carbon emissions are related to the production and distribution of goods. The potential benefits are vast, and include reducing the amount of materials used, shortening and simplifying traditional supply chains, better matching of supply and demand, as well as improving service options that can prolong the life of products. With an additional potential to reduce the weight of vehicles and aircraft to improve fuel efficiency, 3D printing possesses tremendous potential to reduce greenhouse gas emissions and resource consumption.

The use of plastics has recently received a lot of attention. But often times, the best way to address plastics pollution is to not create it at all in the first place. Today, innovations such as HP Multi Jet Fusion 3D printing technology can reduce the amount of materials needed. As the weight is reduced, new breakthrough designs are enabled where the unique structure can add new performance properties that cannot be produced with any other manufacturing technologies. The result is reduced costs per part, decreased energy and resource consumption, and lower greenhouse gas emissions.

![HP Jet Fusion 500/300 Series 3D Printers 140+ Multi Jet Fusion-Printed Parts [Image: HP Inc.]](https://fabbaloo.com/wp-content/uploads/2020/05/8_21_innovation_3d_application_printerparts_inline1_img_5eb098ce60569.jpg)

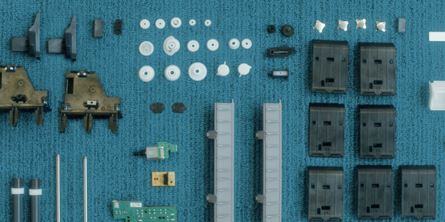

A big piece of this is the circular economy, which is all about keeping materials in use at the highest state of value for the longest possible time. Digital manufacturing and 3D printing play a key role in extending the product lifecycle, disrupting the way products are serviced and recycled for greater long-term viability. We know that extending the life of something like a vehicle has a massive positive carbon footprint impact. Maintaining a digital inventory of 3D printed spare parts has the potential to keep cars on the road longer, or household appliances in use for a greater period of time by keeping supply available after any final buy has been used, or the means of production have been lost.

This same mindset of repair and reuse extends to virtually any industry. For example, some of the biggest brands in furniture and electronics, including HP, have worked together to discover how 3D printing can disrupt the way they make and use spare parts. By integrating repairability, upgradability, reuse and recycling with 3D printing, we can minimize waste streams and start to shift the way people create and consume goods.

3D printing will help companies become more sustainable by enabling them to localize and simplify their supply chains. Since companies can transmit digital files for production locally rather than shipping physical parts and products, 3D printing can lower the emissions related to distribution and warehousing.

What’s more, the value of digital manufacturing gets even more compelling if companies conduct their operations on a cleaner grid, or use electricity from renewable sources, leading to the proliferation of more green and sustainable production practices.

The potential impact of 3D printing to reduce our environmental impact on the Earth is just beginning. We have an incredible opportunity to reinvent how entire industries design, make, and distribute products in a more efficient, economical, and environmentally conscious way. On Earth Day, and every day, we can bring sustainable production to the masses and come together to conserve our resources for the next generation.