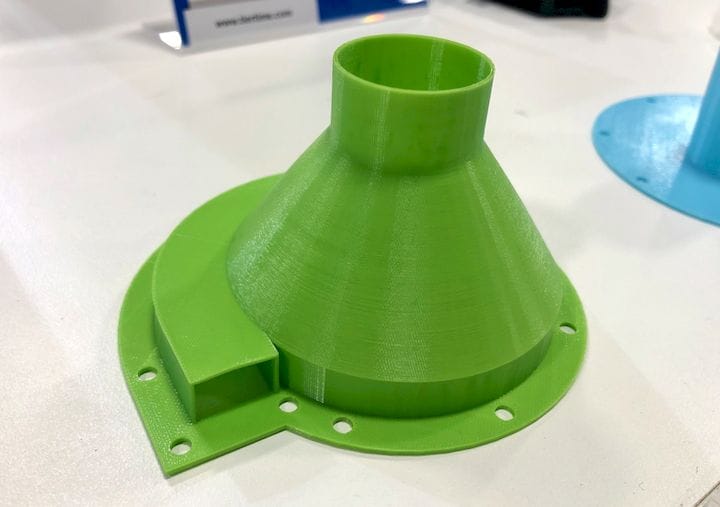

![Could perfect 3D prints be possible with the introduction of new standards? [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/perfect-3d-print-1_img_5eb095219f6ec.jpg)

A reader poses an interesting question about 3D printing standards.

Our recent piece regarding the potential pitfalls of print profile libraries generated some chatter. The article discussed how companies are now building vast libraries of print profiles to ensure their equipment works properly with larger numbers of material options.

The problem with this approach is that it is quite intensive to properly prepare these profiles accurately, and if some companies resort to having user-submitted profiles to their library to save costs, then the quality of the profiles could be compromised.

While these profile libraries are a step forward, perhaps there are bigger and better steps that could be taken. Reader Mike says:

“This is the same problem that faced printer and scanner manufacturers back in the 80’s when the personal computer arrived. Everyone selling printers and scanners had to build drivers for each style of printer and scanner. Then some of us started demanding we develop standard electronic and operating system interfaces. And standard file formats.

That has to happen in the 3D printer industry to make it genuinely universal and not require techno users. Otherwise, the industry will top out too early and most of the suppliers will go out of business.”

I think Mike is on to something very important here. When you take a step back and look at the print profile situation, there is an enormous amount of effort required to build and maintain them, and it will just get exponentially worse as time passes: more and more materials will be introduced by an increasing number of vendors.

What’s missing is standards. But where?

Mike alludes to the creation of standards as they were done for 2D paper printing. The invention of PostScript file format in 1982 created a standard to which all the printers of the day could aspire. Once adopted, it became a given that you could more-or-less readily reproduce a document on theoretically any printer.

That move dramatically opened up the market for 2D printers, and in large part contributed to the massive market for such devices today.

The Postscript of 3D Printing?

Is there a similar step in 3D printing to come?

There may be, although it would be quite different from the PostScript solution, as the 3D printing environment is a lot more physical than paper printing.

In the case of PostScript, we were looking for a way that the input material — a description of a page image — could be described in a generic fashion that could be interpreted by a printer, which would take appropriate actions to produce the image.

For 3D printing the analogous scenario is that the input material — a spool of filament or tub of resin — would have to come with a description of its engineering characteristics so that the 3D printer would be able to adjust its speeds and feeds accordingly.

The print profile library is in a way like that, except it’s hardcoded. Inflexible. Non-automatable. Labor intensive. Subject to error.

And with no future?

Future 3D Printing Standards

![Concept for a future automated profile regime [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09521eb3a0.jpg)

Imagine if materials came with a detailed descriptor of their printing characteristics based on a defined “language” that allowed extensibility, able to accommodate conceivable future materials that don’t even exist yet. This information would be absorbed by slicing software, or even the printers themselves.

In such a world material vendors would be required to post the fundamental descriptor for each of their material types, ready for any printer to use. Then, 3D printers could include an interpreter that could help get the most out of each print job by doing its best to transform the new knowledge of the input material to adjustments in print operations. Vendors could do battle by developing “the best” material interpreter possible.

And users would be free to use, theoretically, any material with a reasonable chance of print success.

Or perhaps I’m just crazy to hope for such a thing.

No one seems to offer collaborative 3D printing modes on dual extrusion devices. We explain why this is the case.