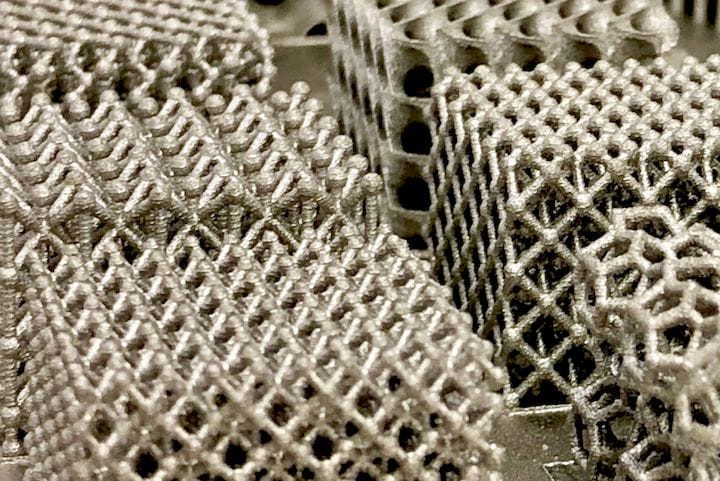

![Some complex metal 3D prints [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09496ba246.jpg)

We’ve learned of a potential issue that some metal 3D printing operations may have.

Many metal 3D printers make use of fine metal powder that is heated to sintering or melt temperatures to create objects. Usually the metal powder is very fine to achieve good print resolution. However, this fine powder tends to get airborne, where it can cause issues.

Airborne metal particles are not only toxic if breathed in, but they can also be quite explosive. Remember, the Space Shuttle used powdered aluminum as its rocket fuel, the same material that is often used in metal 3D printing.

In order to mitigate issues with powder, virtually all competent metal 3D printers are designed with significant safety systems that isolate the powder and even perform heating operations in a non-oxygen atmosphere to prevent any possibility of explosion.

It seems that issues with powder have been accounted for in metal 3D printing operations. But are there other risks? We’ve been informed about another one that might be taking place in some workshops.

In order to establish the non-oxygen atmosphere, gas is usually substituted for ambient air. Typically this is either nitrogen or argon. Of course, these are pricey materials and most systems are set up to re-capture the gas after printing for reuse.

However, the gas must be filtered to allow for a perfect environment on subsequent print jobs. This is done with a recirculating gas filter, which apparently produces a condensate as it operates.

3D Printing Fire Hazard

We’re told that some metal 3D printing operations simply “dump the condensate into a bucket” and store it, because it can be quite expensive to dispose of properly. However, the condensate can be flammable, creating a fire hazard.

It’s therefore possible that some metal 3D print operations, perhaps unbeknownst to their management, may have a storage room full of flammable material.

I’m certainly keen on reducing costs, but one cannot do that by compromising safety, which should always be the number one concern. However, it’s possible some operations are financially stressed due to increasing competition in the metal 3D printing service market and may be unable to properly get the job done.

Short cuts are not always the best idea, especially if they are not safe.

We were able to view video footage of the 3D printing hair-caught incident from last week and have determined exactly how it occurred, and how to prevent it from happening again.