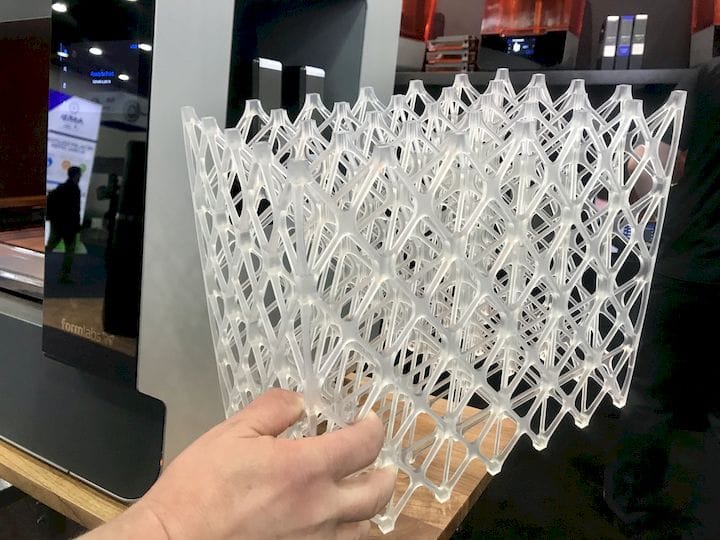

![A part that can only be made with 3D printing technology [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb092370ff5f.jpg)

In recent years we’ve been hearing about a new term called “DfAM”, but I think there’s another category we want to call “ADfAM”.

It started with the introduction of production-capable 3D printers and, in particular, metal 3D printers. Years ago when 3D printing was first introduced the set of possible materials was extremely constrained, and in truth most, if not all, of the materials used were not suitable for production purposes; they were just the few that could print in the relatively primitive technologies of the day.

That effectively relegated 3D printing to the world of prototyping, where it quickly gained popularity. Product designers could quickly gain a physical model of their product concept, far more rapidly than could be achieved with other making technologies.

Then only a few years ago a great many 3D printers gained the ability to 3D print high-performance engineering materials — high-temperature materials like PEEK and ULTEM, for example. At the same time, industry “discovered” metal 3D printing, which could also build production-ready parts.

Then the question arose, “how should parts be made with 3D printing?” Clearly, one could easily 3D print existing part designs — or could you?

3D printers are definitely not “universal making machines” that can print any arbitrary part design. Each 3D printing process has advantages and disadvantages due to the physical nature of their making steps. There are limitations to part size, feature dimensions, overhangs and other geometric aspects.

The key is to create a design that works around the constraints to achieve a fully functional part that leverages 3D printing’s unique ability to create parts that would be impossible in other making processes.

The work required to create such designs is in fact an important skill, one that was not traditionally taught to designers. We call it “DfAM”, or Design for Additive Manufacturing. The specifics would obviously vary by 3D printing process and sometimes by specific vendor equipment, but the intent is the same: make great parts without running into the constraints of the 3D printing process.

As a result of this development, many current designers are not familiar with DfAM techniques and that gap is creating a need in the industry for DfAM training courses. This is a huge development, as I feel it will dramatically drive forward the demand for 3D printing: if more people know how to leverage the technology, more technology will be needed.

DfAM parts are clearly the best way to use 3D printers, and we’re sure to see many more in the future across many industries. We may eventually see some kind of badge or certification for parts to indicate which machines, materials and processes the part was intended for.

But there’s another thing going on.

Many companies hold vast inventories of parts that were designed before the days of DfAM. Some companies wish to move to a “digital inventory” concept that removes the need for managing huge piles of spare parts waiting for customer requests that may never come. Instead they intend on producing them using 3D printing only when required. This should offer massive savings if implemented properly.

The catch is that this is only possible when the old parts just happen to be suitable for 3D printing. Thus these organizations must painstakingly search through their design inventories to identify parts that actually can be 3D printed successfully.

There are several services now available that specialize in this task. 3YOURMIND, for example, offers a service to automatically search through design inventories. They read all the digital design files and examine them for known geometries that would disqualify the part for additive manufacturing. What results is a list of parts that, although previously designed, are still suitable for 3D printing, or at least could be considered further to be 3D printed.

So it seems we have two kinds of part designs suitable for 3D printing: those newly designed parts using DfAM techniques, and those that somehow were already ready to be printed.

That latter group needs a name, and I propose “ADfAM”, for “Accidentally Designed for Additive Manufacturing”, which I think perfectly describes the status of the class of parts.

Do you have ADfAM part designs in your inventory? I bet you do.

No one seems to offer collaborative 3D printing modes on dual extrusion devices. We explain why this is the case.