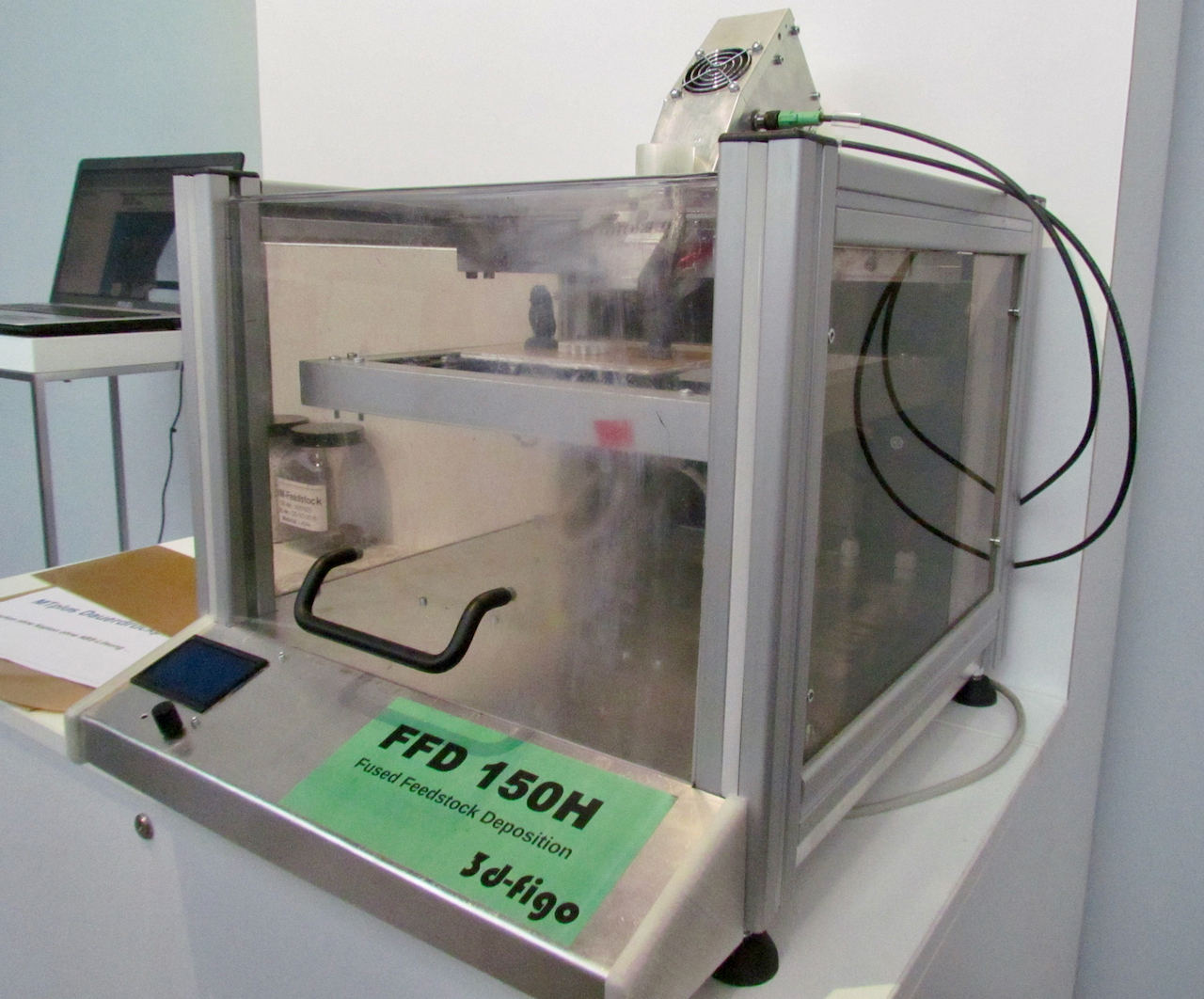

In a very tiny booth on the left side of the FormNext exhibition was a display from a one-person company that just may have figured out a monstrous breakthrough in 3D printing.

Across the show floor our team continually saw inventive 3D printer companies developing new ways to print this or that new material. Some had more success than others, some were able to print one new and unique material, while others could print a few.

But they are all trying to solve the basic problem: Engineers want to print in ANY material they would normally want to use for a given application.

In the world of injection molding, there are literally hundreds of different materials with different properties (and prices) that make up the menu from which designers select plastics. These standard materials are sold in bulk to injection molding factories.

Think about it: an engineer accustomed to using any material they can imagine is faced with using a standard desktop 3D printer that can print PLA, PETG and ABS (poorly). It’s no wonder these machines are not more popular. If only they could use the materials they normally use!

But now, they can.

A tiny German company named 3d-figo has developed a plastic extrusion desktop 3D printer with a difference: it uses pellets instead of filament.

The pellets are in fact the standard injection molding pellets.

Any of them.

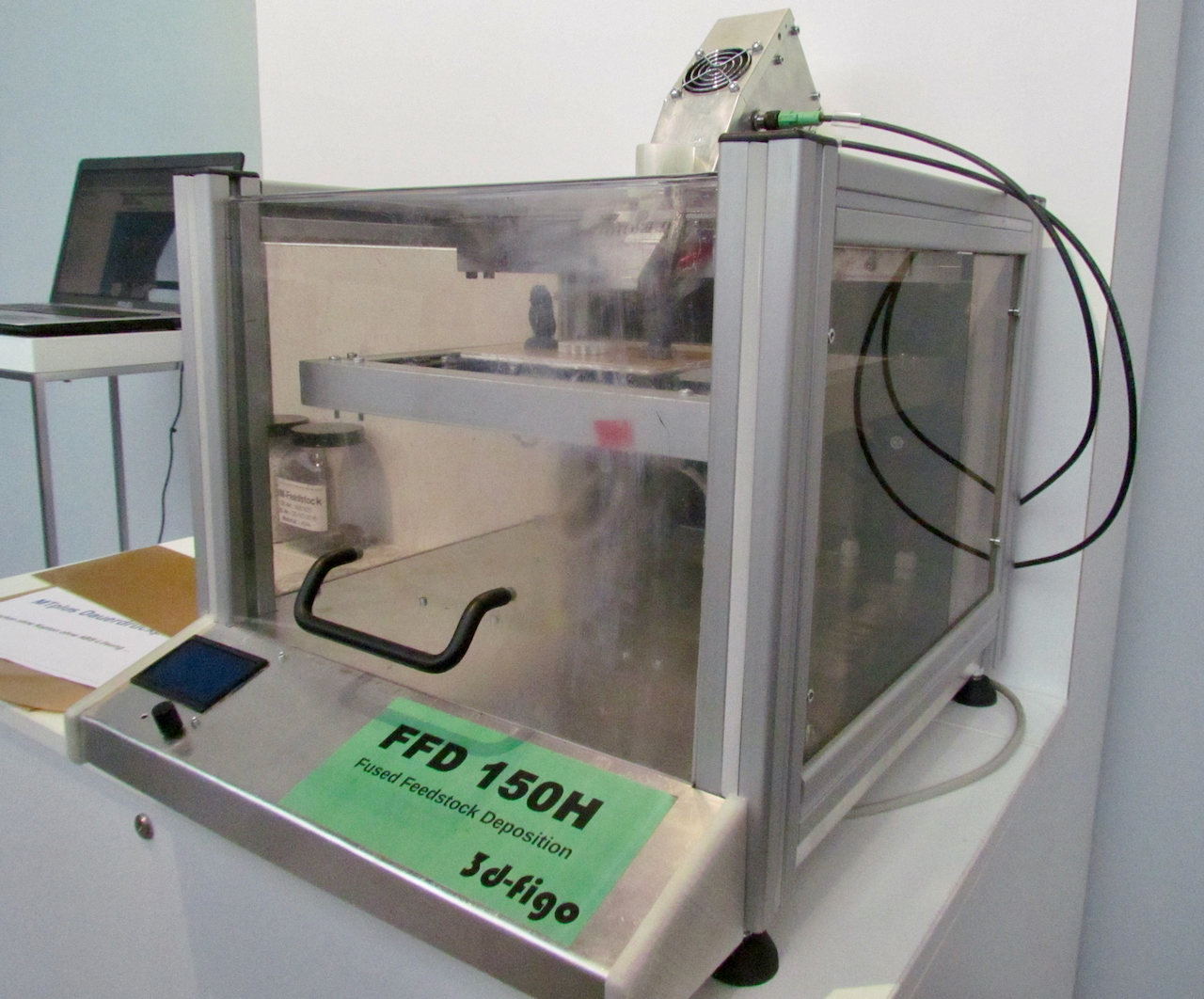

The prototype machine seen at top is a bit rough around the edges, but here you can see the screw-driven pellet extruder.

It includes a hopper where you can clearly see some pellets loaded and ready for action.

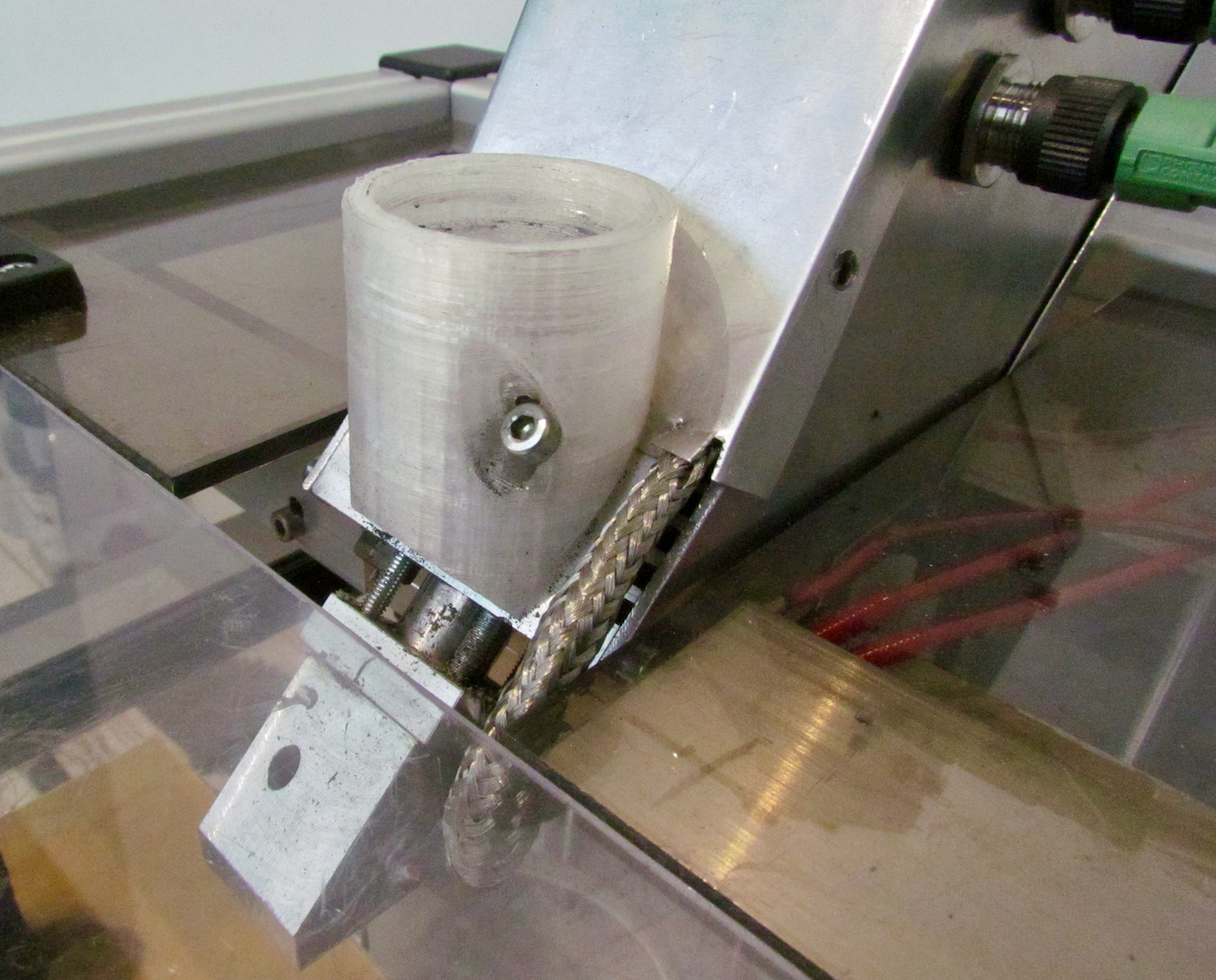

The machine is capable of handling multiple standard injection molding pellets, such as these.

Or these.

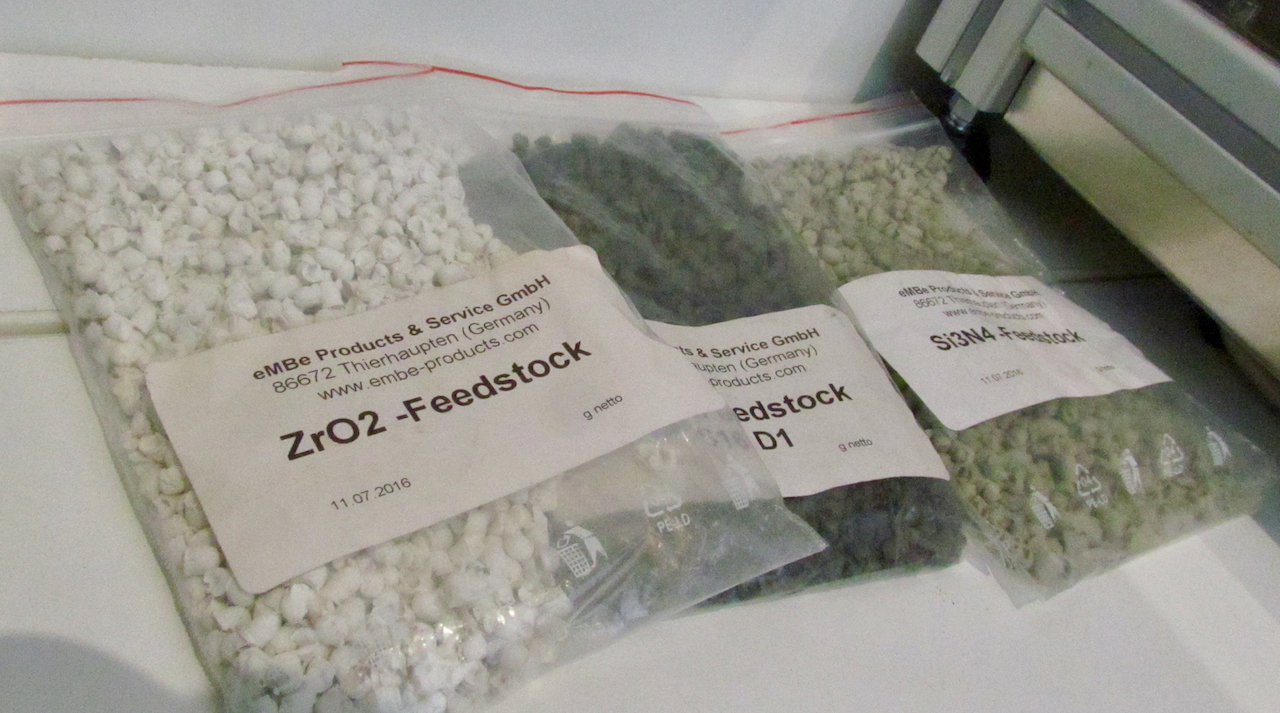

The print samples are not terrific, as you can see here, but remember this is a prototype machine. I am sure that tuning can fix these up, leading to a library of material profiles for use with each of the standard injection molding materials.

The fascinating thing about this idea is that it is so vast in concept. The injection molding industry is very mature and uses such materials commonly around the world – and the materials are not just plastic.

It is possible to injection mold metal and ceramics in this way. The resulting objects are sintered to remove binders and fuse the desired material, at 600-1200C. (Ceramics apparently require a much higher temperature of around 6000C).

For those injection molding companies using such materials, the 3d-figo FFD 150H would be an option enabling them to produce objects WITHOUT a mold! This could be a massive time and money saving concept for those industries. Molds are typically very expensive to produce and thus are usually made only for mass produced items.

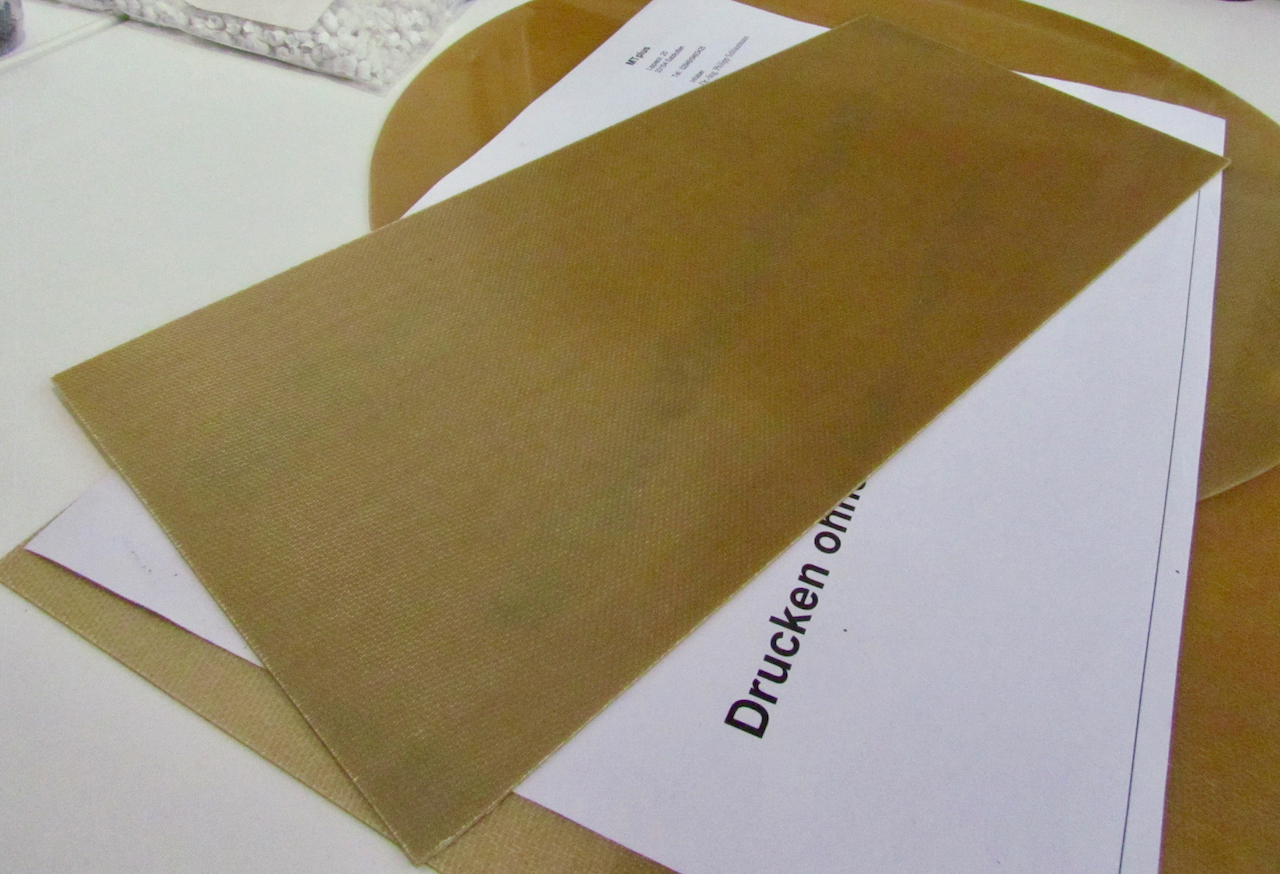

I asked about bed adhesion, as this is a very persistent issue with other machines, and was told that a special surface had been developed specifically for this project, shown here. The surface sticks to all materials except nylon, and has been so effective that it is actually the print surface used in the Made In Space orbiting 3D printer!

3d-figo is the company of Dr. Phillip Schlautmann of northern Germany, who conceived of the idea some 10 years ago, but only in the last two years received investment to proceed. According to Dr. Schlautmann the product will be launched very soon, but it is not clear exactly how this is to be done as their website is not yet active.

Via 3d-figo (Under construction as of this writing)