I learned something new about 3D metal printing that you may not have heard of.

But let’s back up a bit to ensure you understand how most 3D metal printing is done, at least for today. It involves applying high energy to a perfectly flat bed of very fine metal powder. The energy causes the creation of a small “melt pool”, which fuses the loose powder together. By moving the melt pool selectively across the powder bed, you can create layers of metal objects.

This process, as we’ve explained previously, can be spectacularly expensive, as there are a number of other steps required to successfully 3D print metal objects.

The extreme printing cost cuts down the possible buyers of parts to only those whose business can afford it, which typically are medical, aerospace and sometimes automotive industries.

But those very industries require parts that are near-perfect. Aerospace in particular falls in this category, with numerous certifications, audits and standards required to make practical use of the parts.

This all means that metal parts produced with this type of equipment must be as perfectly formed as possible, and this is not only with their shape, but also the internal structures and microscopic metal crystallization from which the part derives its strength and engineering properties.

Thus there are huge efforts undertaken by 3D metal printing operators to achieve the highest quality possible. This is done by endless tuning of parameters, part orientation strategies, support structure thermal optimizations, post processing treatments and much more.

Into the midst of all this, we find the 3D metal printer companies competing against each other. But this is challenging, because, and let’s face it, there aren’t that many ways to blast a laser at a bed of powder.

So what are some companies doing? One approach to getting a leg up on the competition is to speed up prints by using multiple lasers. This enables the printing to take place faster as you have more than one melt pool running around the powder bed solidifying powder.

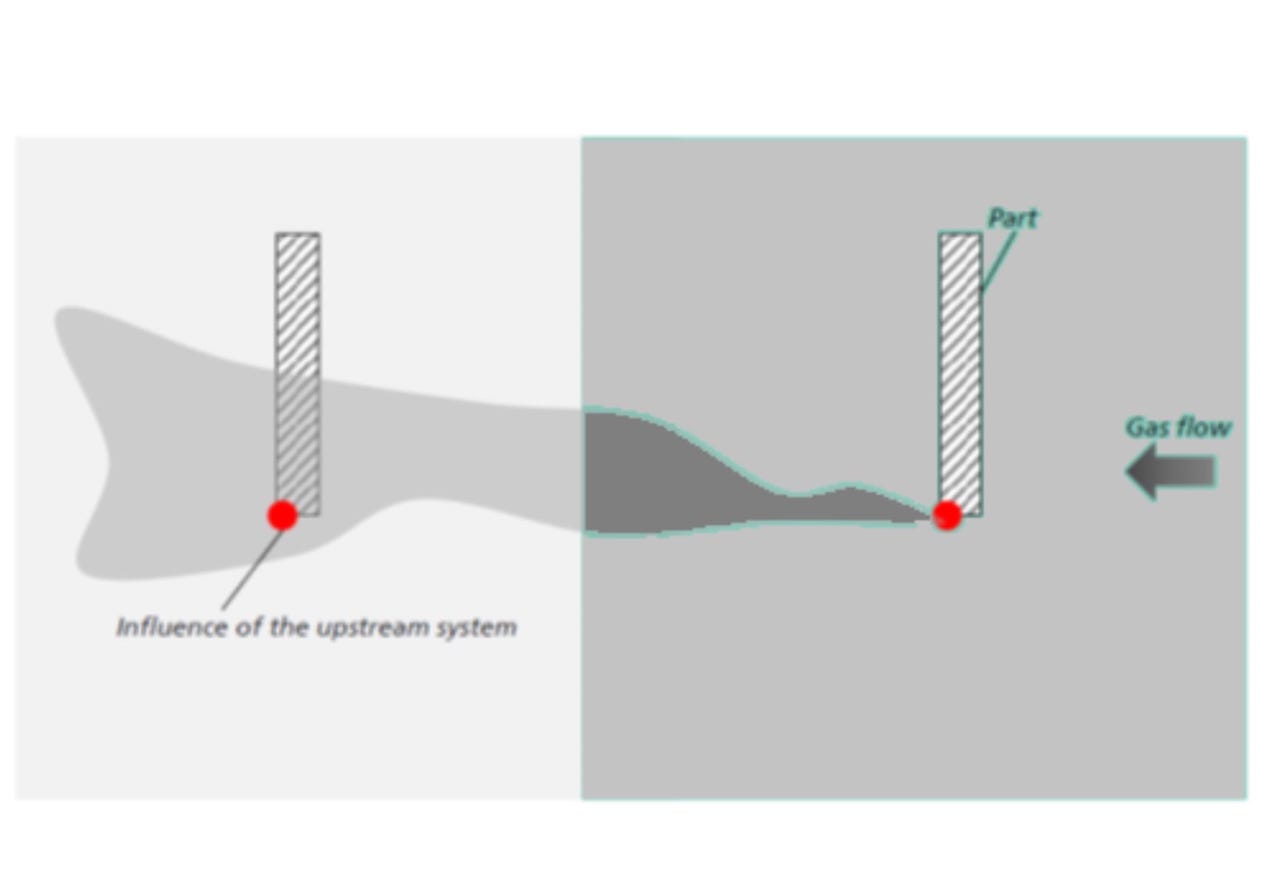

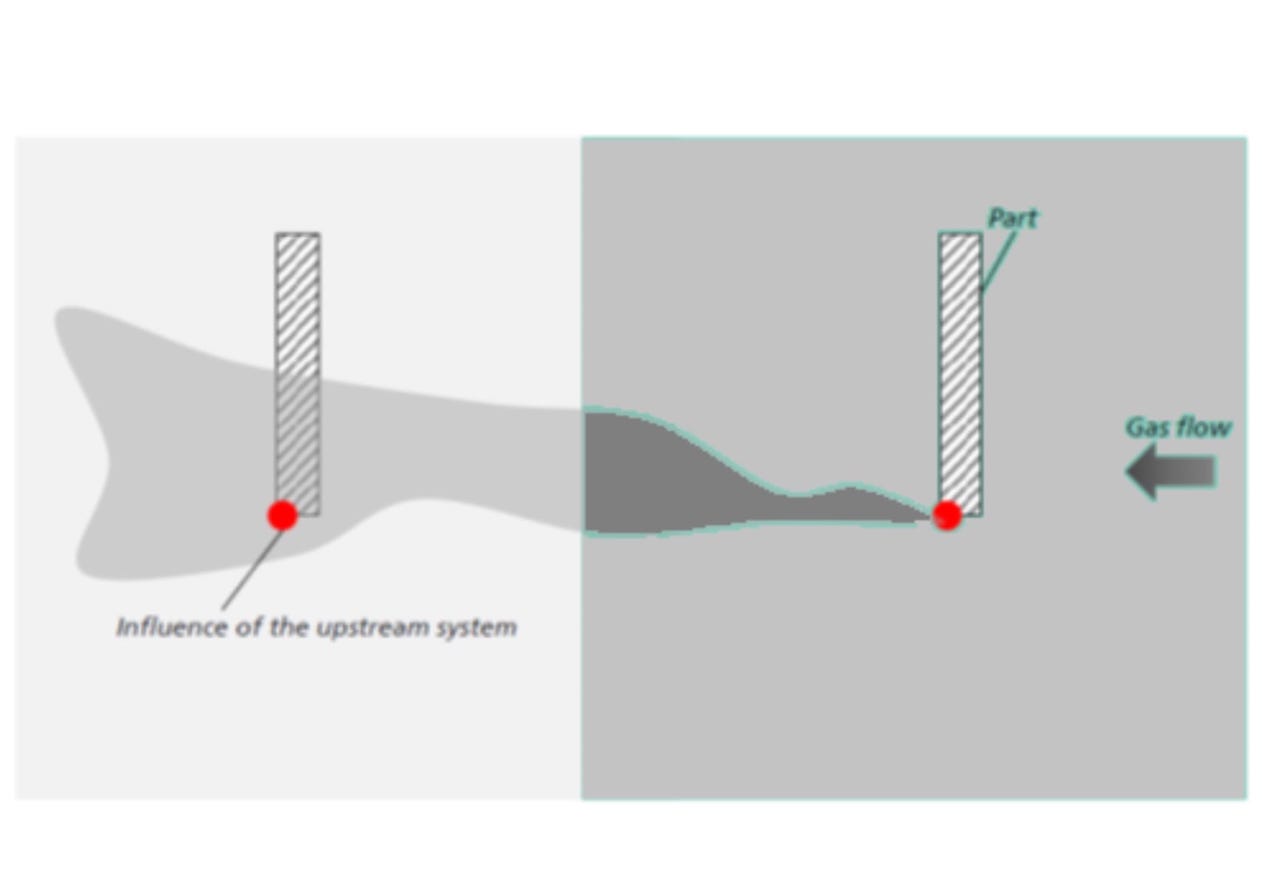

But this approach, to my surprise, introduces yet another problem in 3D metal printing: the smoke and spatter from melt pool “A” can interfere with the laser’s trajectory on melt pool “B”, and so on. If more than two lasers are used, then it gets even more complicated.

The smoke can very slightly alter the laser quality when it impacts the powder, thus changing the quality equation. Sure, it might seem minor, but remember we are looking for perfect parts here.

One company that’s doing something about this is Netherlands-based Additive Industries, who have been developing a simulation system for their equipment. In this way they can observe and work around the smoke flows to ensure the maximum laser quality is deployed throughout a print.

Their new system, which apparently has not yet been released, solves a 3D metal printing issue I didn’t even realize existed.

I checked with a few other vendors and the conversations went something like this:

Fabbaloo: What is your strategy for handling smoke and spatter from multiple lasers interfering with each other?

Multi-laser 3D metal printer vendor: [awkward pause]

Fabbaloo: ?

Vendor: Maybe ask me next year.

I think that appears to be the state of technology with many multi-laser 3D printer vendors. Let’s see if it changes by next year.