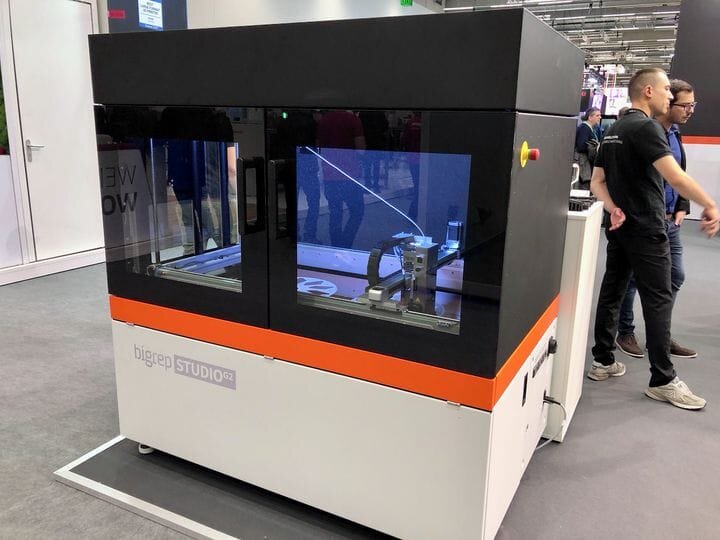

![BigRep’s incredible new MXT 3D print extruder [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a1d9571d2.jpg)

Last week BigRep announced a series of new machines, but what caught my interest most was their MXT extruder.

Let me say this right off the top: this is the single most important advance in 3D printer extrusion technology I’ve yet seen.

After some tantalizing hints earlier this year, the company finally announced two large industrial 3D printers – both of which use the new MXT extrusion technology.

Up to now essentially all 3D printer extruders employed a very simple push and pressure approach: either a gear/wheel mechanism pushed a polymer filament into a hot nozzle, or a screw mechanism pushed polymer pellets into a hot nozzle. These two approaches (but mostly the former) have been the mainstay of 3D printing from desktop to industrial uses.

But there are significant disadvantages to this approach. Because of the distance between the source of the force and the actual nozzle tip, it is actually quite difficult to control the extrusion. For example, if the force is stopped, it takes a slight moment for the material to stop extruding way down at the nozzle. The elasticity of the material introduces inaccuracy.

Another epidemic problem is oozing, where a supposedly stopped extrusion actually drips because there is nothing stopping material from continuing to drip out of the hot nozzle, even if the extrusion force above ceased. This phenomenon has required the introduction of “retraction”, in which the extruder is actually run in reverse briefly to slurp up material away from the nozzle tip in a sometimes successful attempt to prevent drips. However, upon restart the extruder must take into account that it’s backed up the material somewhat.

All of these issues simply go away with the new MXT (Metering Extruder Technology) concept. If you haven’t heard how it works, let me explain.

The material used by the MXT is held in a hot reservoir above the nozzle. Either filament or pellets can be pushed into the reservoir, which quickly softens a relatively large volume of material to just the right viscosity.

At the bottom of the reservoir is a special geared wheel. As the gear rotates, the teeth in the gears pick up a specified amount of softened material from the reservoir.

These polymer “quantums” are passed by the geared wheel down and deposited on the build plate.

What makes the system powerful is the motor driving the geared wheel. BigRep has used a stepper motor. This is a type of motor that is engaged in discrete rotational steps. For example, the controller could tell the motor to run exactly 47 steps, and it would. Or just one. Or 1,019. Or do one step every 16 microseconds. This motor provides complete and utter control over the amount of material being deposited.

If a continuous line of extrusion is required at a particular moment, then the MXT stepper would run continuously. The deposited quantums would obviously bind together as if they were continuously extruded, so there is little difference in the resulting extrusion.

But the increased control allows some very interesting things to happen. One is speed.

The MXT-equipped machines will be able to extrude as fast as the stepper motor can run, and then stop instantly – without any risk of drips.

In a conventional extruder if you try to run the flow very fast, you must overcome the momentum of the flow to stop it, and you can’t. Thus there are limitations to the speed achievable by conventional approaches. That’s now not an issue with the MXT extruder.

An MXT-equipped machine’s toolhead should be able to move around very rapidly, as there are no momentum issues. Turning corners, rapid start/stop and more complex movements will be a breeze.

These capabilities mean the new BigRep equipment should be able to 3D print at vastly higher speeds than conventional 3D printers, which is quite important for BigRep’s traditionally enormous build volumes. I recall their initial machines would run for literally days or even weeks to complete a large print. Now they should be able to punch out prints maybe 20X faster.

And remember, this is their first iteration of the MXT concept. In future years we may see improved versions that can extrude even more rapidly.

Well done, BigRep!

Via BigRep

1 comment

Comments are closed.