Wematter released version 2.0 of their 3D print management software, which includes a number of user interface improvements.

You may not have heard of the Swedish startup company that manufactures industrial 3D printers using the SLS process. Their machine, the “Gravity” is termed by the company to produce the “world’s strongest SLS prints for manufacturing”.

The Gravity may indeed be able to achieve that, and it seems one of the secrets behind the part strength is their Aurora powder. Weather says their powder is of higher quality and results in better prints, as shown in this comparative test:

They demonstrate the strength of the prints made with Aurora powder in this video, where a simple 3D printed chain is used to support an entire human. That’s pretty impressive, as I’ve seen nylon SLS prints that would not survive such a test.

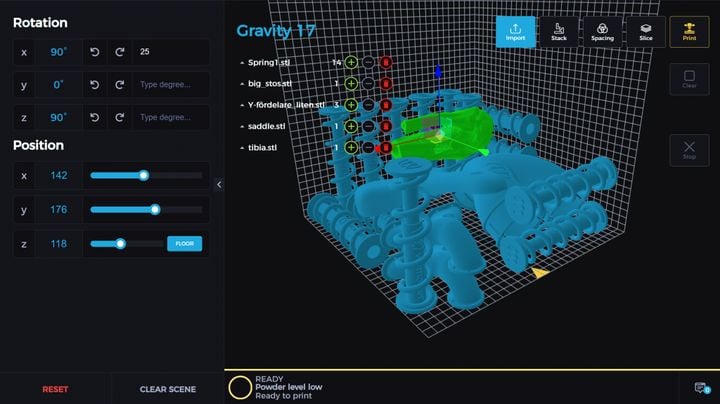

The Gravity is controlled via custom-written software, which Wematter calls “Deep Space”. This tool provides the usual features, but they’ve just updated it to version 2.0. They say:

“A whole new software for the 3D-printer Gravity that takes SLS-technology to the office environment and makes additive manufacturing more user-friendly than ever for product developers and engineers.”

And:

“The focus in the new program has been partly on user-friendliness. For instance in the form of graphical components that show ongoing status in the system. But also on technical functionality that will help engineers to manipulate CAD-models and create as optimal conditions for their 3D-printing as possible.”

What specifically has changed? There’s a number of new features, and yes, most are indeed focused on the user interface. Some that caught my eye were:

- Ability to go back or redo multiple actions if something went wrong

- Possibility to upload multiple files simultaneously while performing other actions

- Option to show or hide certain elements to get a cleaner workspace

- Improved 3D-scene graphics (walls fade in or out depending on the angle to make it easier to see all models)

- Improved menu for 3D-objects (clearer hierarchy for duplicate models)

- Built as Single Page Application. (This prevents the application from requiring new page loads as the user navigates between different sections)

- Menu that makes it easy to switch between the users different 3D-printers

As you can see, these are definitely user-friendly additions to the system.

However, many of these features are similar to those seen on some of the popular slicing systems used for filament-based 3D printing, such as Ultimaker Cura, PrusaSlicer and Simplify3D. Of course, none of those 3D print management systems can work with the Gravity, as the machine uses an entirely different 3D print paradigm. But it’s likely Wematter’s software design could have been influenced by developments in these other software systems.

This is now becoming a bit of an issue for proprietary software systems for 3D printers, as the popular systems are widely supported by many parties and are able to create new features on a regular basis. Meanwhile, 3D printer manufacturers who must produce specialized software systems for their equipment might be unfairly compared to these other systems.

In other words, there may be a bit of pressure to keep up. It’s like a hotel having to compete with the customer service of the car rental company a new guest just experienced: different industry, but similarities exist.

Nevertheless, it’s good to see Wematter improving their software, as it is the most frequently seen element of their system by their customers.

Via Wematter