We caught up recently with Open Additive for a look into how they plan to open up metal additive manufacturing with an affordable, open platform.

The Dayton-based company has made some solid progress since we spoke in person last spring. The mission hasn’t changed, as Open Additive looks to meet more needs in metal 3D printing with their customizable systems offering:

- Open Architecture

- Open Configuration

- Open Materials

- Open Parameters

- Open Sensing

- Open Maintenance

I spoke with Paul Hollowaty, Global Sales Manager and Dr. Olga Ivanova, Chief Scientist, AM Applications for updates into Open Additive as of spring 2020.

Open Additive

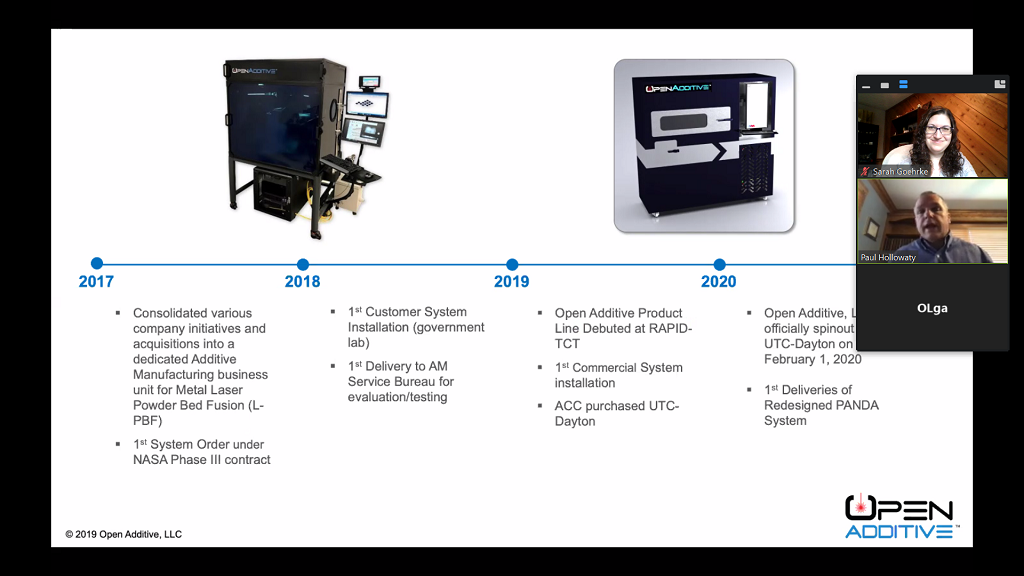

The company itself is based in Beavercreek, Ohio, just outside of Dayton. In 2017, operations began as a business unit of UTC, working with what Hollowaty describes as a “very agile, very experienced additive manufacturing team.”

“We started as a business unit of UTC, with the first project under a NASA Phase III contract designed to be a completely open architecture. We sold about four of those, to a university, a contract manufacturer, a community college, and NASA. We saw the need for a more industrialized system while maintaining the same open architecture,” he said.

In 2019, a company called ACC purchased UTC-Dayton, and a plan was set in motion for Open Additive to eventually spin out. This move became official on 1 February 2020.

Open & Affordable Metal 3D Printing Platform

Open Additive is continuing to progress on its open architecture path; they wanted to come up with an industrialized solution that could fit into a variety of environments in the right configuration for each installation.

The company discusses what they do as “a platform, as opposed to a model number, because that’s what we’re trying to do with open architecture: create a system that can be configured to your needs before the sale or after the sale,” Hollowaty noted.

That’s where those six key features of openness, bullet pointed above, come into play.

This fully open architecture approach isn’t especially common in additive manufacturing today. While that’s a nice differentiating statistic, that’s not where the company wants to focus — it’s all about what that openness can inspire and enable.

“We have openness in mind from the outside; there’s enough physical space within the process chamber to add open configurations like sensing mechanisms and electronics. What this is doing is reducing the customer’s risk of obsolescence,” Hollowaty explained. “What we’re seeing and what we have seen is that companies using open architecture systems are developing new technologies faster.”

To Hollowaty’s point about configuring before or after the sale, he noted that while the preference is for setting everything up first, and it may be more difficult after the fact, it’s very possible. This can indeed stave off obsolescence as more capabilities can be added or adjusted as future needs become clearer or new technologies (sensors, lasers, build area reduction sleeves, etc.) become available to fit the system.

Open Additive is “a machine builder first” — but not only. The team are working on more than $4M in research projects as of the time of our conversation: “A lot of those tie in to what we’re doing to bring this technology further.”

The research focus fits in with what they’ve been experiencing with existing installations and upcoming orders. Not having restrictions on materials or sources allows for “enough control for researchers to do what they need to do, and probably even more than a contract manufacturer would want.” To that end, he added, “we do have the ability to ‘dumb it down’ to simplify the process to upload material, choose material, and process your part.”

Open sensing also means that Open Additive can integrate their own sensing package, a third party package — “or you can do it yourself.” The system is designed with pre-drilled holes in the top plate so cameras can easily be mounted.

Further, the system’s open maintenance construction can reduce downtime by enabling customers to do their own minor repairs.

“A lot of systems are closed so you can’t even do simple repairs without a repair person.We have a quarterly maintenance service plan, and we really want to make users self-sufficient so if, in the second year for instance, you don’t need it you could choose not to renew the warranty,” Hollowaty said.

Open Additive PANDA System

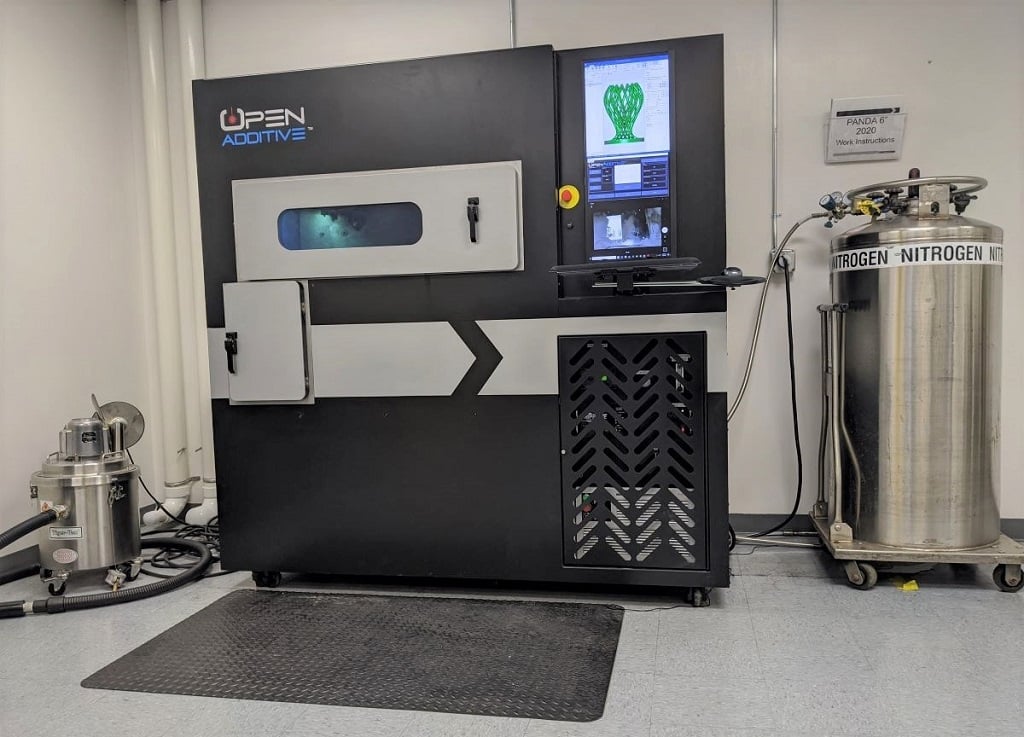

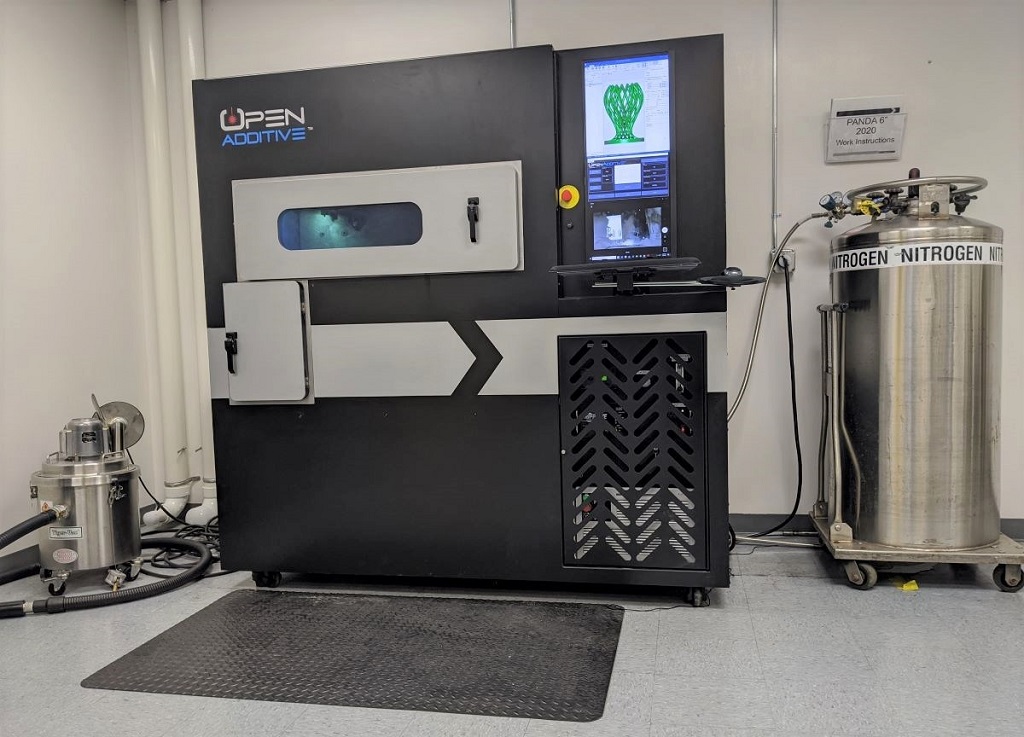

Last month, the company revealed the redesigned PANDA system, as seen at the top of this article.

It looks a bit more like a production system than at our initial introduction last year, though looks of course aren’t everything. Some key features include:

- Multiple build size options

- Configurable lasers/optics

- Powerful control software

- Advanced process monitoring

- No materials restrictions

- Safe for reactive powders

While being open, there are some standards available for standard and large build volumes. Similarly, there are standard and advanced configurations for laser and optics for the L-PBF system.

The 6” PANDA model specs include:

- Build Volume: 6.0” x 6.0” x 9.5”

- Laser/Optics: 500 W IPG Air-Cooled Yb Fiber

- Laser with High Performance Galvo

- Workstation: Windows 10 Workstation w/29” Monitor

- Materials: Reactive and Non-Reactive Powders

- External Dimensions: 76” (L) x 28.5” (D) x 78” (H)

- Weight: 1,000 lbs.

- Machine Price: $169,000

For the larger 11” PANDA, specs include:

- Build Volume: 11.0” x 11.0” x 12.5”

- Laser/Optics: 500 W IPG Air-Cooled Yb Fiber Laser with High Performance Galvo

- Workstation: Windows 10 Workstation w/29” Monitor

- Materials: Reactive and Non-Reactive Powders

- External Dimensions: 76” (L) x 28.5” (D) x 78” (H)

- Weight: 1,250 lbs.

- Machine Price: $199,000

Open Additive is opening doors for configurable, industrialized metal 3D printing.