Since the beginning of this year, the COVID-19 outbreak has demonstrated the fragility of global supply chains that provide life-saving equipment including ventilators, masks and other personal protective equipment (PPE) to medical facilities around the world.

3D Printing and The Supply Chain

3D printing has long emphasized its power to decentralize global manufacturing by manufacturing locally, but the material with which it operates is still beholden to the global supply chain.

The pro-decentralization argument in favor of additive manufacturing systems generally goes something like this: global supply chains require huge amounts of transportation. Since additive manufacturing systems 3D print products on site without expensive tooling from a 3D design file, the cost of shipping and production is reduced. CAD files are easy to reverse engineer and easy to redesign, greatly reducing time-to-market as well. Prior to the COVID-19 outbreak, this argument was not airtight by any means.

The cost of producing certain non-essential and essential goods (including medical supplies) was still cheaper by traditional methods like injection molding and transcontinental shipping.

However, the 3D printing community has risen to fill in the medical supply chain gaps caused by the pandemic. The global supply chain was thrown off-kilter by the sudden skyrocketing demand for essential goods, complicated by sudden trade restrictions and difficulties imposed by countries hoping to contain their local outbreaks. Producing hundreds of designs that address medical supply shortages to both the medical industry and the general population, the global 3D printing community continues to be incredibly helpful to the general population and medical communities around the globe affected by the current health crisis.

As of this week, there are approximately 5,800,000 known COVID-19 cases reported around the world. About 360,000 people have died since the virus broke out of Wuhan, China in January of 2020. France has reported approximately 186,000 cases so far with nearly 30,000 casualties and 70,000 recoveries.

Covid3D.org

One hospital in Paris began developing a plan to address the sharply increasing deficit of hospital beds, essential services and essential equipment due to the pandemic. This hospital is 3D printing medical equipment around the clock and using another 3D technology, 3D scanning to perform quality control on all the parts produced. Led by a surgeon in Paris, a new operation was launched to 3D print more medical supplies on demand using the Artec 3D Space Spider for the rigorous quality control necessary to improve.

An initiative led by Paris-based surgeon Dr. Roman Khonsari, along with the Paris hospital authority APHP (Assistance Publique – Hôpitaux de Paris) began Covid3D.org.

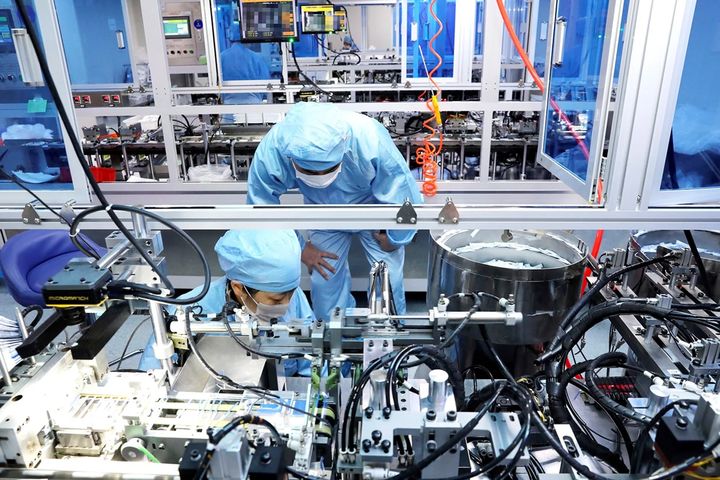

With funding from the University of Paris and luxury group Kering, the group planned to leverage 3D technology to build a large 24/7 factory in the hospital to produce essential medical equipment badly in demand due to the newly warped global supply chain of medical goods. The goods needed to be 3D printed rapidly, efficiently and cost-effectively.

Fifty engineers, developers, entrepreneurs and doctors mobilized around the initiative, and in ten days, Covid3D had officially launched.

Read more at ENGINEERING.com