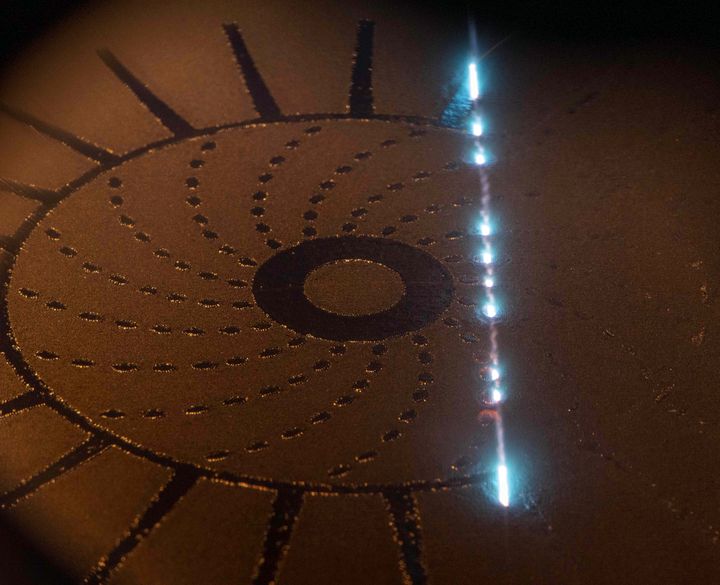

Wayland Additive has introduced a new metal 3D printing process they call “NeuBeam”.

Wayland Additive is a UK-based startup operation that seems to have been around for only a year or so. During that time they have developed a new form of metal 3D printing that is based on the familiar powder bed approach, but offers some interesting advantages.

Wayland Additive says:

“NeuBeam technology has been developed in-house from the ground up by a team of physicists that have worked for many decades with electron beam technology and industrial systems in the semi-conductor industry. The science, combined with extensive expertise and experience has allowed Wayland Additive to develop a very capable and reliable system rather than imitating existing systems or adapting off-the-shelf components and re-purposing them.”

Issues With Powder Bed 3D Printing

Before you can understand NeuBeam, you must understand the advantages and disadvantages of the two main powder bed fusion (PBF) metal 3D printing processes used today.

One PBF process uses lasers. A powerful laser sweeps across a flat bed of metal powder, selectively sintering the powder in layers. When a job is complete, an object is pulled out of the powder-filled build chamber and post-processed. This approach is used by many metal 3D printer manufacturers.

The other PBF process uses an electron beam instead of a laser. Electron beam melting (EBM) has long been used by ARCAM, now owned by GE Additive. The beam melts the fine metal powder in a similar fashion to produce objects.

Laser PBF tends to produce objects with finer details and better surface quality simply due to the pinpoint nature of the laser. However, the extreme power of the laser causes complex heat flows within the print, leading to the need for complex support structures to transfer heat, and the corresponding removal of said structures during expensive post-processing.

Electron beam PBF processes are a bit different in that they can print objects at a more rapid speed because the electron energy is more readily absorbed by the metal powder than laser light. The results are a bit more coarse, but that can be workable for larger parts.

The big issue with EBM, according to Wayland Additive, is that there are significant constraints. Wayland Additive CEO Will Richardson said:

“It is no secret that existing Laser and eBeam PBF systems come with limitations, some of them prohibitive. With Laser PBF, the internal residual stresses that the process generates requires extensive structural supports to prevent the parts distorting or cracking during the print process. Sometimes these supports require as much material to manufacture as the parts themselves. Removing them post-build typically requires the use of wire EDM and machining operations, which are expensive and time consuming. The parts typically also require stress-relieving in a furnace post-build – another operation, more cost, and another piece of equipment to maintain and run.”

Wayland Additive Business Development Director Peter Hansford added:

“The traditional eBeam PBF process faces its own challenges and constraints, most notably the instability of the process caused by charge accumulation within the build chamber. This can result in powder scattering or a so-called ‘smoke event’ that distorts the current layer of the build and therefore compromises the entire build. To avoid this, the process has to be operated in a very specific way, and has a steep learning curve. Particularly, it is critical to maintain the temperature of the powder bed between strict limits, which is required to cause the powder bed to sinter so that it isn’t disturbed by powder charging. This unreliability means that eBeam PBF has typically been considered less favourable than laser-based PBF.”

NeuBeam 3D Printer

Wayland Additive has overcome many of these constraints with their new process, “NeuBeam”.

While superficially similar to EBM, NeuBeam has a way to neutralize the electrical charge developed during normal EBM operations. Richardson explained the difference between the two:

“Unlike the traditional eBeam PBF process, the charging issues that make EBM so unstable have been fully neutralized with NeuBeam using core physics principles developed in the demanding semi-conductor industry. Moreover, NeuBeam is a hot part process rather than a hot bed process. This efficiently creates parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed, ensuring free-flowing powder post-build (no sinter cake) and stress free parts with reduced energy consumption.”

In theory then, the NeuBeam process should be able to handle more types of materials and geometries successfully than traditional PBF processes. And it can also do so with less need for support materials. Wayland Additive says there are “no residual thermal stresses” and “no gas cross-flow”, which will clearly simply job set up to a notable degree.

Currently Wayland Additive has merely announced their technology, but has yet to announce a machine using the NeuBeam process. I’m very interested to see further developments of this unique technology.

Via Wayland Additive