A startup company has developed services to assist the transition to additive manufacturing technologies.

I spoke with Omer Blaier, the CEO of CASTOR Technologies, who have developed a sophisticated decision management software system for analyzing 3D models. Their service should be of great interest to any company considering an introduction of additive manufacturing techniques into their operations.

What Is A Decision Management System?

A decision management system is an increasingly frequently found style of application in which a highly complex situation is reduced to a simple decision. In today’s world there are oceans of data that could be used to make a decision, and often the amount of data is far larger than can be practically reviewed by a human analyst.

Decision management systems use AI and machine learning techniques to quickly sift through large amounts of data to make determinations. As the amount of data available has increased, so has the availability of AI algorithms and the processing power to execute them.

These have been combined into software known as a “decision management system”, where the data is reduced into a very simple form that a human can easily analyze and make a decision.

It’s easy to get overwhelmed, but decision management systems can reduce the available data into straightforward “A vs B” decisions that are far easier to deal with. For operations with repeated and standard decisions to make, a decision management system is an obvious advantage.

CASTOR Decision Management

CASTOR has built a decision management system for additive manufacturing, based on extensive knowledge of the technology, equipment, materials and other factors for the “leading technologies of industrial 3D printing”, including FDM, SLS, SLA, etc.

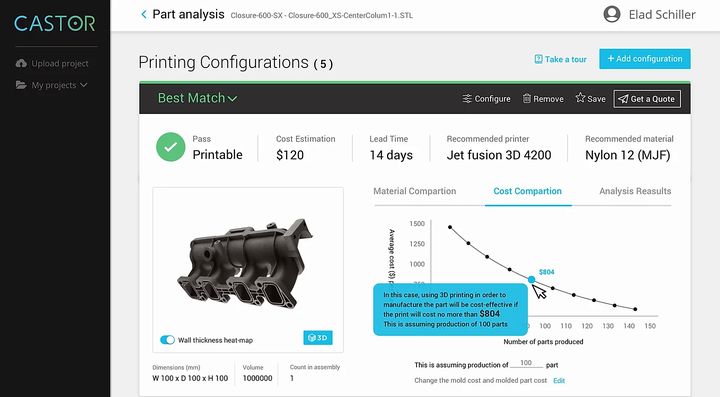

It works by having the client upload one or more 3D models and having them analyzed by CASTOR. Currently they accept STL, STP and STEP file formats. The system then performs an analysis, repairing the files if required.

Blaier explained the system attempts to help with three key aspects of a decision about an analyzed part: geometry, materials, and economics.

For geometry, CASTOR will review the 3D model to ensure it is 3D printable by examining the thickness of walls, holes, intersections, normals and whether the part should really be considered a “2D” part.

Material analysis will review the 3D model opposite CASTOR’s extensive materials database, and attempts to find the 3D printable material that best matches the specified material from the original part’s design, which is often not available for 3D printing. Instead, the best match that can be 3D printed is found by CASTOR.

Finally, the economic decision is the most interesting to me. Here CASTOR will develop an estimate for how much it might cost to produce the given part using the recommended 3D print configuration. That’s similar to a quote, but here is where it’s quite fascinating: CASTOR will also develop the estimated cost for non-3D print manufacturing, specifically injection molding.

By having both costs computed, the system can then recommend a decision on whether it is feasible to produce the part using additive manufacturing technology. In some cases it is actually not recommended to use additive technologies, as it doesn’t make economic sense. Essentially, they are determining the break-even point for traditional vs. additive manufacturing.

There’s one other tricky aspect to the economic analysis: CASTOR’s estimates are of the true cost to produce the part, which can be different from the cost charged. For workshops using internal 3D printing services, these estimated costs are likely good, but for an external service you may find the charged cost to be more than CASTOR’s estimate due to the need for variable profit margins, as well as differences in automated quoting algorithms.

Blaier says the entire process is completely automated, and could, for example, allow a company to inspect a large quantity (thousands) of part designs to determine whether savings could be made by using additive manufacturing processes.

Blaier emphasized that the service is “meant for additive manufacturing experts”, and that it can go over a full bill of materials (BOM).

There are potential top line savings, according to Blaier, who said it is possible to reduce inventory. This approach might involve identifying a part that could be 3D printed on demand, rather than being stocked in inventory.

CASTOR Corporate Progress

Blaier told me they began the company in 2017 and launched CASTOR Pro at Formnext. Currently they have twelve staff, and have over 80 clients.

They have analyzed over 30,000 parts in beta testing, and it seems the service is valued, as they have experienced 20% month-by-month growth in system use.

Blaier said the company is in a growth phase, and is in fact hiring more staff.

The company offers several different variations of their product, each of which addresses different client needs.

CASTOR Pro is their SaaS solution, where one can simply subscribe on their website and use the service online as required. CASTOR offers a variety of subscription plans to fit different needs. Blaier says the price is determined by the number of parts analyzed per year.

For companies concerned about uploading secret 3D designs to the Internet, CASTOR offers an on-premises version of the software where all data can remain internally controlled. This option could be very important for military, government, or other organizations.

Finally, CASTOR offers a white label service, in which their software can be used under license by a third party, but be branded by the third party. Thus, if you see a company offering this type of service, it just might be CASTOR under the covers.

CASTOR seems to offer an intriguing product that will be of significant interest to certain manufacturers. In these days of turmoil, CASTOR’s decision management systems could be a way to help transform a company into a more efficient additive manufacturing mode.