BigRep announced the availability of two new materials for their large-format 3D printers, ABS and ASA.

Hold on there, you might be thinking “what’s the big deal with ABS and ASA? They are incredibly common 3D print materials!”

You’d be quite correct, but the difference here is that single word, “big”.

Large-Format ABS

While virtually all 3D printers these days are able to 3D print ABS and ASA materials, for many years that hasn’t been the case with large-format 3D printers. The reason for this absence has been, well, thermal.

ABS is well known as a troublesome 3D print material. This is due to its tendency to expand when heated and shrink when cooled. That’s something many materials do, but ABS does it more than many other 3D print materials, especially PLA. The heating of ABS when it is extruded, followed by rapid cooling, causes warps and distortions in the print, and sometimes print failure if a misbehaving 3D print peels off the print surface.

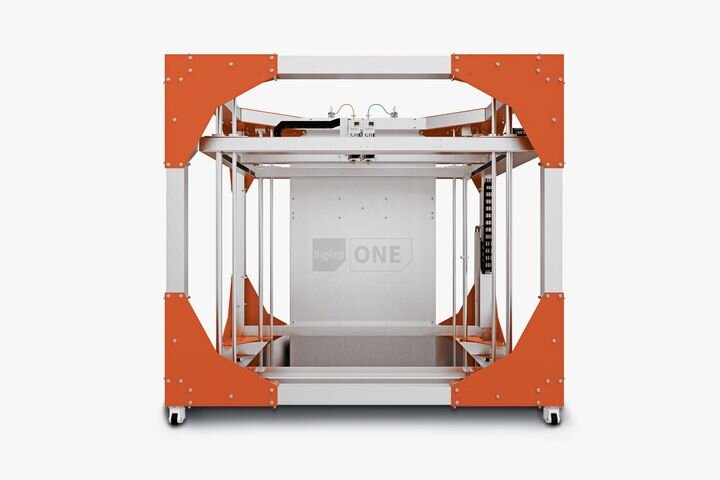

These issues have been solved by application of heated print surfaces and heated build chambers, but this was not possible on the earlier BigRep devices. Here we see the BigRep One, their initial flagship device that is still in use around the world:

As you can see, the BigRep One would have tremendous difficulty in heating the print due to its open-style design. Thus BigRep and makers of similar large-format 3D printers would specifically avoid warp-prone materials such as ABS. Typically they would 3D print with PLA or similar well-behaved materials.

At one point BigRep attempted to overcome the problem by using chemistry rather than machine design. They developed their own high-temperature PLA-style mixes that were somewhat stronger and with higher heat resistance, but did not warp like ABS.

These materials were helpful to BigRep’s clients who would often 3D print large prototypes and then coat them with paint. However, without good heat resistance these prints would soften at commonly encountered temperatures. This would limit the possible 3D print applications.

BigRep ASA and ABS

Now the company is finally 3D printing large objects with true ABS!

I suspect one of the main enablers of this change is that the company’s recent machines are all enclosed, a far cry from the open format initial devices. The enclosed nature allows them to capture heat and decrease the temperature gradient during 3D printing, thus reducing or even eliminating warping.

These new materials will certainly change the game for BigRep, as they can be considered engineering materials. Years ago I realized that many engineers would not buy a 3D printer “unless it can use material X”. And often, “X” is ABS. I’m expecting to see a burst of sales for the company.

The other material involved is ASA, which is chemically similar to ABS and has pretty much the same warp properties. But the main difference is that it, unlike ABS, is UV-resistant. This means it can be used in outdoor applications without the need for a covering.

Again, this new outdoor capability will certainly open up new clients to BigRep’s equipment, as very large objects are often found outside. Now these companies can 3D print such objects with the new ASA capability.

BigRep’s materials portfolio now includes: ABS, ASA, PET-Carbon Fiber, PLX, BVOH (water soluble support), High Temperature, PA6/66, TPU (flexible), PRO HT, PVA (soluble support), PETG and last but not least, PLA.

Very good moves by BigRep.

Via BigRep