Most people have used a microscope at some point in their lives for either work or school.

We learn that microscopy uses specialized lenses to enhance the visibility of small particulate matter from organisms and tissue, among other things.

Spectroscopy is a bit different, in that it uses electromagnetic radiation to determine the transmittance or absorbance of a sample, lending clues to the sample’s structure, molecular composition, and other characteristics.

A standard spectroscopic microscope must be placed at a very small distance from the sample. This can lead to measurement issues at very low temperatures or in pulsed high magnetic fields.

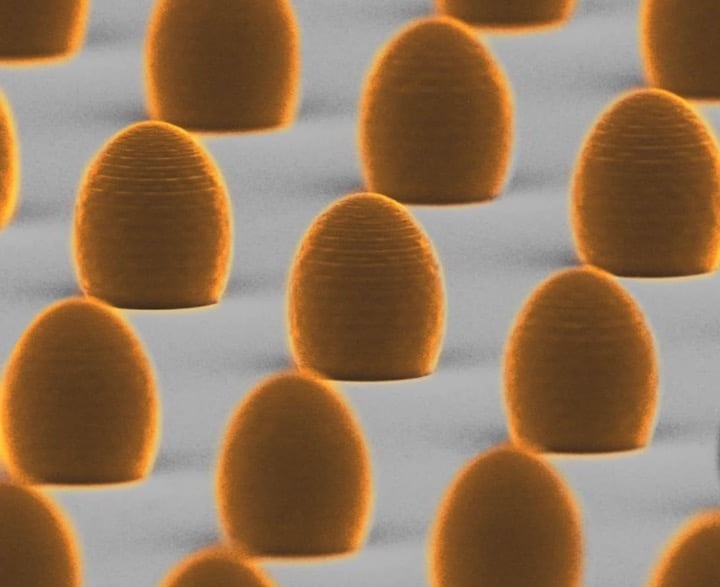

In a recent paper written by researchers at the University of Warsaw titled “Ultra-long-working-distance spectroscopy of single nanostructures with a spherical solid immersion microlenses,” a 3D printing technique known as direct laser writing (DLW) was used to manufacture microlenses aimed at enhancing long-distance spectroscopy.

The advantages of using DLW 3D printing (which leverages two-photon lithography) include its rapid printing speed. The researchers describe how they were able to 3D print hundreds of microlenses onto a sample. The microlenses were 3D printed in arrays to produce a coordinate system that the researchers used as a map to pinpoint the location of a given nano object. In turn, this capability allowed the researchers to accurately distribute the same experiments to labs all over the world, where measurements could be independently verified.

Read more at ENGINEERING.com