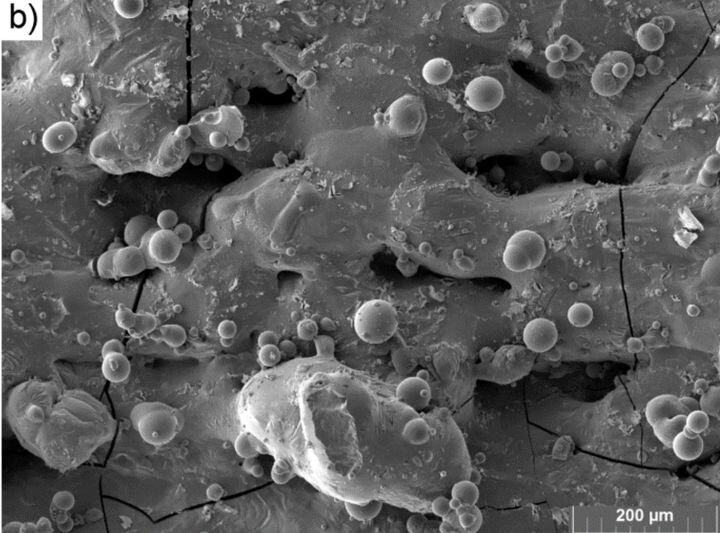

![Microscopic look at the surface of a 3D printed magnet [Source: MDPI]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08b7f0714a.jpg)

New research has discovered an approach for 3D printing magnets of strength matching conventional manufacturing techniques.

The casual citizen might not think much of magnets, but they are an increasingly important component in many of todays devices and equipment. Magnets are the key to creating electric motors, which are deployed everywhere these days. You probably have one in your pocket: the vibrator in your smartphone is an electric motor that requires a magnet.

Magnets have been produced using conventional means for decades, and these have been used effectively in many industrial and consumer applications. However, there is a desire to be able to 3D print magnets, particularly the NdFeB type, which offers the strongest magnetic field at room temperature.

The idea is that just as other materials were 3D printed in “impossible” geometries enabling new possible applications, perhaps magnets can take a similar advantage through 3D printing.

The problem is that they cannot effectively be 3D printed.

Early attempts at 3D printing magnets found the resulting magnetic strength to be significantly less than magnets of the same size made conventionally. Why so?

One reason was due to the 3D printing processes. It was found in an earlier study that the presence of binder (as a powder bed / fusion approach was used) mixed with the magnetic particles decreased the strength.

Other researchers attempted to overcome this by increasing the density of magnetic particles in different 3D printing processes. However, these attempts came up short because the particles were somehow demagnetizing themselves during 3D printing. The resulting magnets would have, for example, only 60% of the equivalent strength.

Now, Austrian researchers seem to have figured out what’s going on in their paper entitled, “Influence of Melt-Pool Stability in 3D Printing of NdFeB Magnets on Density and Magnetic Properties”. They performed numerous experiments of this type, but varied the 3D printing parameters of each attempt. They varied the layer size, laser power, laser speed and other parameters in an attempt to understand what factors played the most important role in demagnetization.

They explain their approach and findings:

“The influence of changing laser power, scanning speed, and powder layer thickness on density, porosity structure, microstructure, phase composition, and magnetic properties were investigated. The results showed that energy density coupled with powder layer thickness plays a crucial role in melt-track stability.

It was possible to manufacture magnets of both high relative density and high magnetic properties. Magnetization tests showed a significant correlation between the shape of the demagnetization curve and the layer height. While small layer heights are beneficial for sufficient magnetic properties, the remaining main parameters tend to affect the magnetic properties less.“

In other words, they figured out the best 3D printing parameters to 3D print so-called “super magnets”. With this development, it should now be possible for commercial ventures to experiment with the approach and perhaps develop new magnetic applications that could assist in the electrification of the world.

Via MDPI (Hat tip to Benjamin)