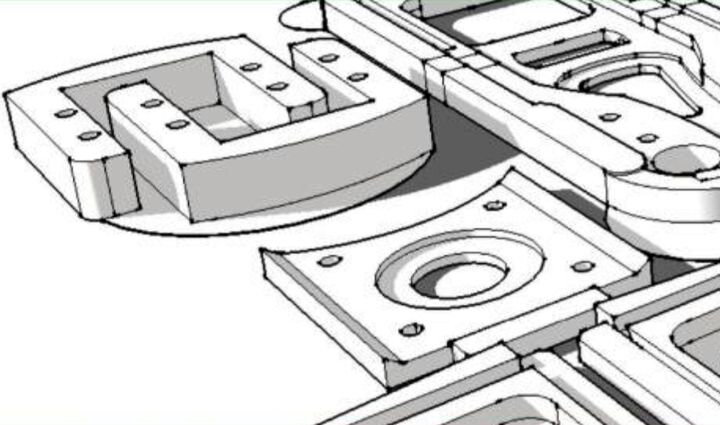

![Functional Design for 3D Printing [Source: Amazon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050accfc94.jpg)

This week’s selection is “Functional Design for 3D Printing: Designing 3d printed things for everyday use – 3rd edition” by Clifford T. Smyth.

Those new to 3D printing eventually face the question, “what do I print?” That turns out to be a rather difficult question to answer. It’s easy to find pre-made designs on public repositories, like Thingiverse or YouMagine, but eventually one tires of those options and the process of learning how to design one’s own 3D models using CAD software happens.

Beginning CAD designers may learn the software to some degree, but then there is the issue of “what is the best way to design this object?” That is not something that is typically taught in CAD tutorials.

Enter this book, which attempts to do so.

Smyth discusses a number of aspects that deal with the ultimate strength of a 3D printed part, including infill patterns, nozzle movement, the concept of anisotropy, and permeability.

He investigates the constraints of 3D printers, particularly with the use of support structures, which are usually troublesome in one way or another.

I’m impressed that six pages are dedicated to the topic of bed adhesion, which is perhaps the number one cause of 3D print failures. If it doesn’t stick to the bed, then it won’t print.

There is a discussion about part strength, including a number of definitions that can help you understand the nature of the problem more deeply. Then Smyth looks at the main points of failure for 3D printed parts, including layers. The idea is to be able to identify where the failures might occur while you are designing the part, and then rectify them before they occur.

Finally, the book proceeds to take you through a series of case studies on different parts and their designs.

This is an excellent book for the more advanced 3D printer operator who wishes to increase the reliability of printing and of the parts themselves.

Via Amazon