![Struggling through a tricky 3D printer build [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c276984b.jpg)

After building several 3D printer kits over the years, there seems to be a change in design from manufacturers.

While desktop 3D printer products are now labeled as “Assembled” or “Kits”, there really are two kinds of kits.

Detailed 3D Printer Kits

The first kind of “kit” is what you might expect to see when that word is used: a pile of small components requiring considerable assembly effort.

![Some of the many parts required to build an early desktop 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c27b946a.jpg)

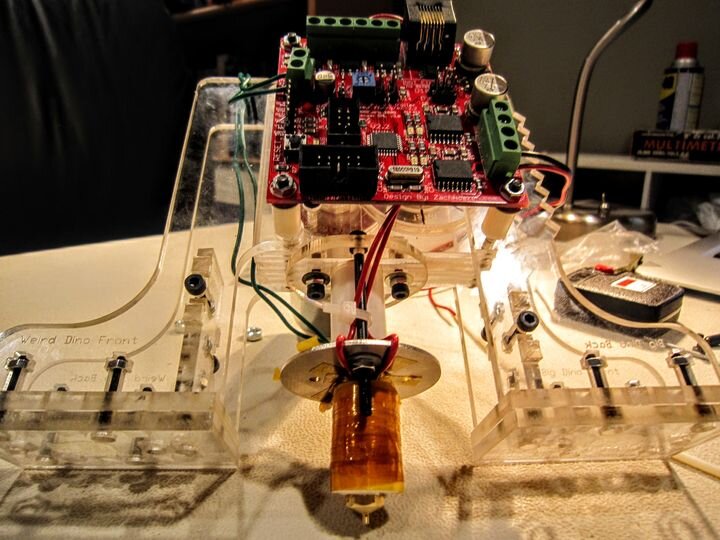

My first experience with this type of kit was with the venerable MakerBot CupCake, which I obtained in 2010. It was literally that, a pile of small parts, including bolts, wires, laser-cut wood & acrylic, PCBs, and other bits and pieces, as you can see here. As this was the first 3D printer I’d assembled, it took quite a while. Twenty hours, if I recall.

It was quite a project, and I learned a lot. However, it was way too much for anyone but those totally committed to finishing the job.

![Extrusion mechanism on the original MakerBot CupCake desktop 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c280ac4c.jpg)

The results were actually not good. Here we see the extruder mechanism on the CupCake. At the bottom you can see the nozzle, and the heating apparatus above it. Heating was achieved by running current through a nichrome wire, which was HAND WOUND around the hot end.

3D Printer Assembly Problems

This demonstrates the problem with this type of assembly: I might have wound the wire 27 times, but someone else doing the same assembly might have done 29 rounds. As a result, the two machines would have different thermal characteristics.

This made it incredibly difficult to properly tune the machine, since print parameters found on a forum might not work in your machine. That’s because all the machines were ever-so-slightly different from each other.

The good news is that modern 3D printer kits of this type don’t exhibit that problem; they are designed to end up almost identical once assembled properly.

Simplified 3D Printer Assembly

But there is a second type of assembly kit I’ve been seeing lately, and although it would legally be classified as “assembly”, the work is quite a bit different from the CupCake-style assembly experience.

In this second category the machine is basically already fully assembled, but it is segmented into two or three large pieces for shipment. The pieces can be organized to allow for much smaller package dimensions.

To “assemble” such kits one simply bolts the few pieces together and plugs in a few wires. That is so utterly different from the other type of kit it’s hardly fair to even call it a “kit”. Almost anyone can succeed building one of these.

There’s another benefit here: the manufacturers are pretty much assured that all the machines will be functionally identical, as opposed to kits requiring significant amount of low-level construction steps.

In some cases the amount of time required to “assemble” one of these “kits” and get the machine up and running is about the duration as setting up a fully assembled machine. That’s because even in the so-called “assembled” machines you still have to remove stablizing foam chunks, immobilizing tie-wraps and sometimes plug in a few things.

If that’s the case, is there any real difference between these “kits” and “assembled” 3D printers in terms of setup?

I think we need a new set of terms to clarify this three-way scenario: “Fully assembled”, “Kit” and … what? Do you have a suggestion?