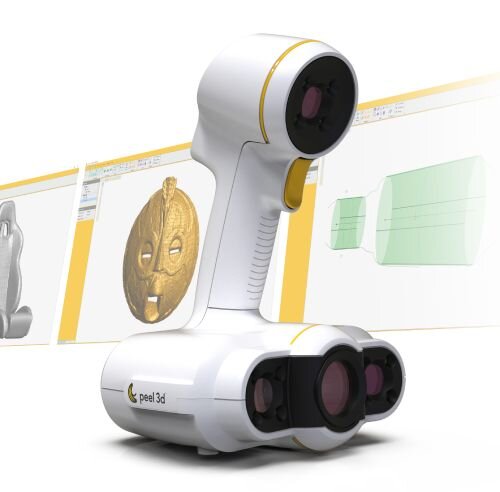

![The peel 2 CAD 3D Scanner [Source: peel 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/peel-2-CAD-scanner_600x600_img_5eb08c0809e9a.jpg)

Quebec-based peel 3D has been producing a series of relatively inexpensive industrial handheld 3D scanners for a couple of years now.

Their latest product, the peel 2 CAD, is an improvement on their prior models, the peel 1 and peel 2. The new model includes some specification improvements, but the key feature is a built-in ability to perform reverse engineering.

Reverse Engineering with 3D Scanner

Reverse engineering is one of the key use cases for handheld 3D scanners of this caliber. The usual scenario is a part for which there is no 3D model, yet physical copies must be made. Reverse engineering is a process to create that missing 3D model, which can then be modified or manufacturing in some way, including through 3D printing.

For those unfamiliar with the details of reverse engineering in this way, it usually starts by capturing a somewhat detailed 3D scan of the part. Then this raw 3D scan is imported into a CAD tool. CAD functions are then used to essentially “trace” on top of the 3D scan, gradually re-building the missing 3D model while adhering to the intended shape.

Then, the 3D scan is tossed out, as it is no longer required: the 3D model has been reconstructed.

This is the traditional workflow for reverse engineering, and it is somewhat tedious, as the designer must identify shapes within the 3D scan and then assign the appropriate 3D geometry to it.

peel 2 CAD Reverse Engineering

The peel 2 CAD intends on simplifying this workflow, possibly quite significantly. They explain:

“peel 2 CAD is an easy-to-use and fully integrated solution that enables you to extract all the information you need from your 3D scans and send them right to your preferred CAD software. You can directly scan objects of many sizes and surfaces—without any prep work—as the scanner recognizes shapes automatically. peel 2 CAD also comes with a calibration certificate so that you gain peace of mind knowing you are not sacrificing on performance.”

This sounds like peel 3D might chop out an entire — and tedious — step in reverse engineering by having the 3D scanner & its software itself perform the necessary work. If this truly works, it is a very good thing. On the other hand, it may be that the CAD recognition process is a step-by-step aid, rather than an entirely automatic process.

I say “if it works”, as I am curious as to how this is actually done. I am wondering if there are limits to the peel 2 CAD’s ability to recognize shapes: could there be a geometry that it cannot properly reconstruct? Would the operator have to resort to manually defining CAD geometry in some cases? I don’t know and won’t until we see some examples from peel 3D.

The peel 2 CAD can then produce CAD-style file format output, including .IGES, .STEP and .DXF formats. They also say the output is compatible with “SOLIDWORKS, Inventor, PTC and more”.

How does this work? It seems that the “smarts” are in a special software module that accompanies the usual peel 3D software, which runs on an adjacent PC during 3D scanning operations. This software contains tools to not only run the 3D scanner itself, but also to analyze and refine the captured 3D model before transferring it onward for further processing.

Those readers frequently performing reverse engineering should be interested in the peel 2 CAD. It’s also possible the device could be of interest to those who infrequently perform reverse engineering and are less efficient at the manual CAD build process: the peel 2 CAD might be able to do the job faster.

peel 2 CAD Specifications

Aside from the powerful CAD features, the peel 2 CAD has two other technical improvements:

-

The accuracy has been improved from 0.25mm to 0.10mm

-

The volumetric accuracy has improved from 0.5mm/m to 0.3mm/m

Perhaps the most interesting feature of the peel 2 CAD device is its price: US$9,690. That’s a far cry from other 3D scanners I’ve encountered in the past priced at 5X or even 10X this price.

The price performance ratio for 3D scanning just improved.

Via peel 3D