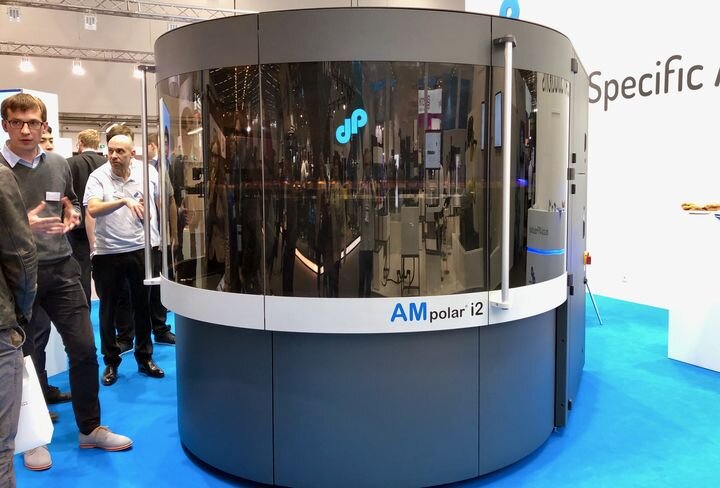

![The AMpolar i2 industrial 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c102b354.jpg)

The AMpolar i2 is about the most unusual 3D printer you might encounter.

The large, industrial-sized device, made by Germany-based dp polar, uses what they call the “High Speed Rotative (HSR) AM process.

The machine is based on the familiar liquid photopolymer resin process, where a light source selectively solidifies the resin into 3D objects. However, dp polar seems to have developed a highly unusual motion system to engage that process.

AMpolar HSR Rotative

Rather than having a traditional cartesian X-Y-Z motion system, the AMpolar i2 uses a large, rotating disc as its build platform. It’s basically a flat donut shape that spins around the build chamber.

Meanwhile, there is a large print head that can be lowered to the print surface. In this print head are a large number of high resolution inkjet nozzles that can selectively deposit photopolymer, which is then solidified with a light source.

![Rotating build platform on the AMpolar i2 industrial 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c107a803.jpg)

The print head moves on the Z-axis, while the rotating build surface moves all areas under it during a single rotation. The rotation speed is surprisingly rapid for such a large device, but it’s possible because inkjet technology is now quite mature.

Imagine the speed of large printing presses; this is similar to what happens in the AMpolar i2. Droplets are easily deposited in precisely the correct locations at a very high speed.

This means the device should have reasonably good throughput, as the size of the circular build plate is some two square meters. dp polar says:

“AMpolar® i2 delivers unparalleled output of printed parts per time unit, resulting in a significant reduction in costs per part.”

One concern I had is that the diameter of the inner portion of the build plate is less than that of the outer diameter. That’s obvious due to geometry, but it means that the outer nozzles must deposit at a somewhat greater speed than the inner nozzles in order to maintain the same resolution. Based on the sample parts, it seems that dp polar has figured that out by timing everything properly.

AMpolar Pick and Place

One very interesting feature of the AMpolar i2 is that it can apparently be matched with a pick-and-place system. This would enable a part to include an embedded component, such as electronics, sensors, etc. To accomplish this, the 3D printing would pause while the rotation allows the pick-and-place unit to drop components into half-built cells in the prints. Then 3D printing would resume and cover over the embedded component.

AMpolar i2 Materials

dp polar offers three resins for the AMpolar i2, including a “tough” basic material, as well as a flexible material. There’s also a support material, which is likely required for every 3D print as overhangs are most probably not possible with this 3D printing process.

The AMpolar i2 is said to be multimaterial. It’s not quite clear what this means, as it could indicate only the use of a pair of model and support materials.

Polar Style 3D Printers

The only other “polar” style 3D printer I’m aware of is the Polar 3D, which we saw a few years ago. This was a desktop device, far different from the clearly industrial-capable AMpolar i2.

I’m not sure how this unusual concept will be received by industry, but the idea seems quite sound as it is based on well-known principles. I expect the AMpolar i2 will attract attention from some manufacturers looking for high throughput with the materials offered by dp polar.

Via dp polar