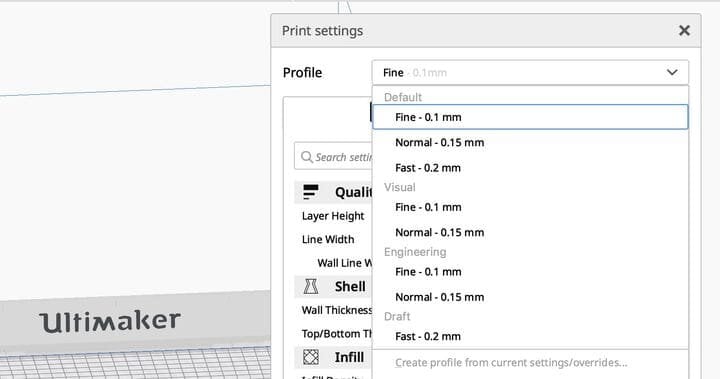

![A glimpse of the new Intent Profiles in Ultimaker Cura 4.4.0 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08cbdc4057.jpg)

Ultimaker released Ultimaker Cura 4.4.0, the latest version of their popular 3D print slicing software.

While nominally produced by Ultimaker for managing its own 3D printer products, the company has generously open sourced the code for Ultimaker Cura and thus it is used by countless other 3D printer manufacturers as a sophisticated management tool.

Periodically, Ultimaker releases updates to the software that typically add new and interesting features, as well as increase performance. These re always welcome, of course, but in the 4.4.0 update I noticed something a bit different that is quite interesting.

Print profiles are a long-accepted feature of 3D printer slicing software. These are essentially pre-made packages of parameters to save the operator the bother of typing in the specific series of numbers representing that printing configuration.

Current print profiles found in most slicing software are focused around the layer size. A profile with a very thin layer size, which would take far longer to 3D print, would be named “Detail” or “High Resolution”. A profile with a coarse layer size would be “Draft”, or “Quick”.

Intent Profiles

Now Ultimaker seems to be introducing a new concept that resonates strongly with me. They call it “Intent Profiles”.

Instead of choosing “A”, “B” or “C” layer size profiles, they instead name the profiles based on the intent of the operator; in other words, how the completed 3D print will be used. Here are their descriptions of possible Intent Profiles:

-

‘Draft’ Intended for initial prototypes and concept validation, and will print your design in the shortest time possible.

-

‘Engineering’ Intended for high-dimensional accuracy, to print functional prototypes and mechanical end-use parts.

-

‘Visual’ Intended for visual prototypes and prints that need excellent aesthetic quality.

These profiles would include not just layer size differences, but an entire inter-related suite of parameters optimized to achieve the goal of the profile. In a way, this also reflects the accumulation of increasingly powerful 3D printing parameters that have appeared in Ultimaker Cura over the years. This is a way of accessing them properly and in a very convenient manner.

At this point these built-in Intent Profiles are only available for use with Ultimaker’s S3 and S5 3D printers with specific materials. However, there is nothing stopping anyone from creating their own intent profiles.

Self-Made Intent Profiles

I can imagine this concept being implemented in various ways depending on the environment of the 3D printing operation. Imagine intent profiles such as “Production”, “Production High Quality”, “Personalized”, or “Extra Strong” and many other possibilities.

This concept could be implemented on any slicing software that offers the ability to save profiles, although I suspect the capability is not frequently used. It should be used a lot more. But it takes some effort to set them up, perhaps explaining the infrequent use.

Meanwhile, Ultimaker’s pre-cooked Intent Profiles are instantly ready-to-go and there’s little effort required to use them, so long as you have the right equipment and materials.

Ultimaker Cura New Features

The new Ultimaker Cura 4.4.0 includes a few other new features of note, including he ability to more easily tweak specific print parameters, and an interesting pause feature. The pause feature allows the display of a custom message on the machine’s front panel to provoke the operator to perform a specific task.

Ultimaker’s example scenario includes a message like ‘Place 626 bearings in slots now’. I suspect this could be performed multiple times during a single print, leading to some interesting complex 3D prints.

Ultimaker has also, as is customary, increased performance of Ultimaker Cura slightly, and added compatibility for a number of new third party 3D printers by means of user-submitted profiles.

Via Ultimaker