![The Lynxter S600D 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c8c324fa.jpg)

I had a chat with the friendly folks at Lynxter, the French startup producing unusual 3D printers.

Last year our first encounter with them revealed an incredibly sophisticated 3D printer capable of industrial use. Their S600D was a rare combination of features:

-

Large delta-style machine

-

Fully enclosed and actively heated build chamber

-

Swappable toolhead

-

Water-cooled hot ends

-

Capable of 3D printing in high temperature materials

-

Full air filtration system

-

Swappable build plates to match the material being 3D printed

What is new at Lynxter?

It seems that the company has expanded tremendously, likely due to the very attractive combination of advanced features on the S600D. I was told they are now 13 people, whereas a year previously there were only three!

They’ve also raised €1.5M (US$1.7M) in investment to power their expansion plans. They have been selling product in their home country of France, but now are piloting sales elsewhere. In fact, they say they are seeking resellers and distributors. If you’re one of those, you might want to give Lynxter a shout.

Technically, Lynxter still offers the S600D 3D printer as their platform, but they’ve done some enhancements.

Lynxter Liquid Extruder

![Lynxter S500D 3D printer liquid extruder [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c8c8a4a5.jpg)

The most important advancement is the addition of a “liquid” toolhead. This takes advantage of the S600D’s modular architecture that allows quick swapping of toolheads and print plates for different materials.

The liquid toolhead is a syringe-like device that allows 3D printing of a very unusual set of materials, including:

-

Acetoxy silicone

-

Alcoxy silicone

-

LRS silicone

-

Resins

-

Polyurethane

-

Wax

I’m not sure there is another device that can 3D print in such an unusual set of materials.

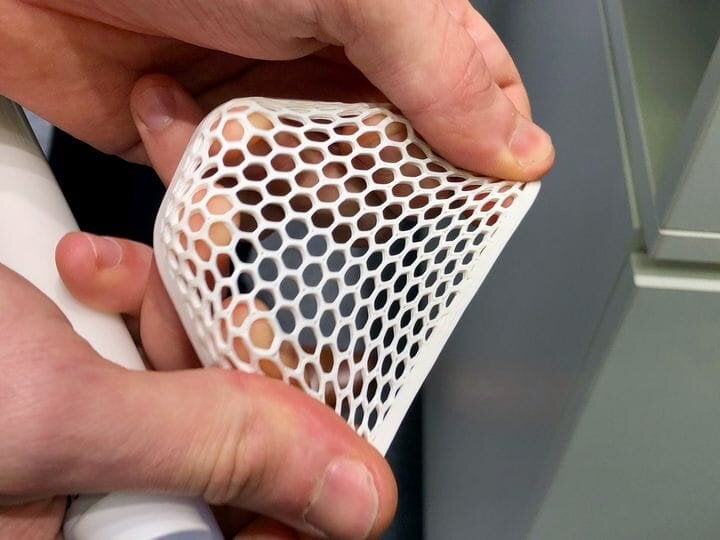

![Lynxter flexible 3D print [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c8cc96e9.jpg)

They are also now able to 3D print ceramics using the green / debinding / sintering approach. They can 3D print objects in alumina or even cordierite.

I’m quite impressed with the Lynxter S600D and its ever-expanding feature set. Now I’m wondering what else they could add to the device.

Via Lynxter