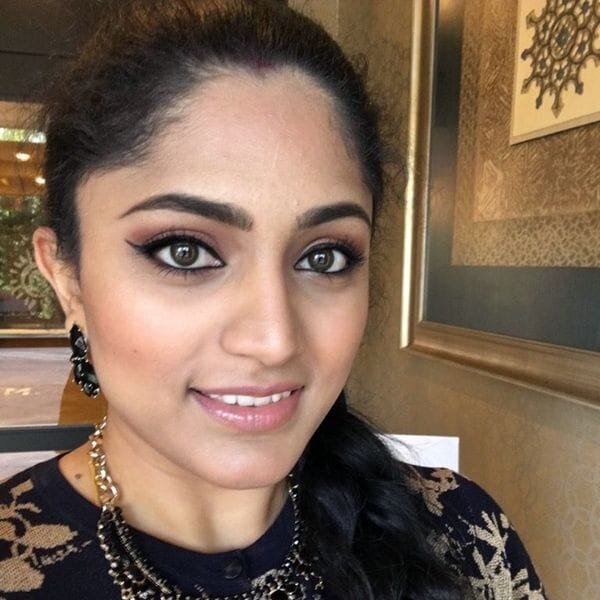

![Ranjani Ravikumar [Source: Women in 3D Printing]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d05c54e8.jpg)

Ranjani Ravikumar works as a Supplier Quality Engineer at Xometry.

She completed a Masters of Nanomaterials from NCSU in 2018 and prior to that, a Bachelor of Engineering & Management in Materials Engineering (Nanomaterials) from McMaster University in 2014. Since the beginning of her tenure at Xometry, Ranjani has come to be known as a reliable SME for 3D printing processes and ensuring on-time delivery of products while educating customers who need technical assistance with their prototyping needs.

Prior to this, she worked for Arcelor-Mittal Dofasco (the largest steel manufacturer in the world) and Mold-Masters (a hot runner injection molding company), gaining a variety of experience across multiple industries that eventually led to a career in 3D printing. Eventually, she envisions being at the forefront of providing consumers 3D printing solutions through the use of novel and innovative materials.

Nora Toure: Ranjani, could you let us know about your background and what brought you to 3D printing in the first place?

Ranjani Ravikumar: My undergrad and post-grad degrees are in Materials Engineering, specifically Nanomaterials Engineering. Previous to Xometry, I had worked for an injection molding company and a steel manufacturer in Canada.

After moving to the US, I was given the opportunity to work at Xometry where I had my first exposure to 3D printing. I already had a great interest in it from coursework I had done in my undergrad degree, so I took up the opportunity to see how laser sintering, FDM, and other processes worked hands-on.

Nora Toure: Can you describe your very first experience with 3D Printing?

Ranjani Ravikumar: My very first experience with 3D printing occurred when I started with Xometry. I had heard of 3D printing in the past, but never had any hands-on or practical experience that allowed me to see it in action.

Once I started at Xometry, I got to work with our in-house additive team and many of our partners and, from there, learned a great deal about 3D printing including DfAM (Design for AM). Of course, coming from a materials engineering background allowed me to apply certain concepts in greater detail and from there, a great interest was nurtured and developed.

Nora Toure: How does your experience working in steel manufacturing at Arcelor-Mittal help you in your current career in 3D Printing?

Ranjani Ravikumar: Working in steel manufacturing allowed me to understand the manufacturing and post-processing of 3D printed metals, specifically stainless steel. Understanding the different heat treatments and finishing possible for various grades of steel, it was easy to apply that same knowledge to 3D printed metal.

Read the rest at Women in 3D Printing