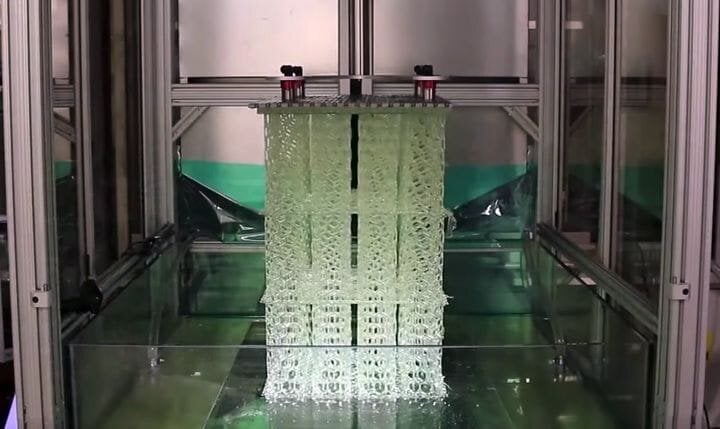

![Experimental very high speed HARP 3D printer [Source: Science]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d6a2df97.jpg) Experimental very high speed HARP 3D printer [Source: Science]

Experimental very high speed HARP 3D printer [Source: Science]

Researchers from Northwestern University have developed a new 3D printing process they call “HARP”.

This is a rather interesting development, and adds to the increasing repertoire of methods to speedily 3D print objects in photopolymer resin.

Resin 3D Printing Challenges

The problem being solved is bed adhesion. In most resin-based 3D printers, light is focused through the transparent bottom of a resin tank, where it impacts the resin and selectively solidifies a layer of the print.

Then the problem happens: the newly solidified layer is very often stuck to the transparent tank bottom and must be carefully peeled off. The peeling operation takes considerable time to perform, dramatically slowing 3D printing operations.

There are now several companies offering solutions to this issue, such as Carbon’s patented oxygen inhibitor layer, or others with slippery resin tanks. These allow printing to occur much faster as the peel delay is reduced or eliminated.

HARP 3D Printing Process

HARP, or High Area Rapid Printing, uses a recirculating oil to prevent print adhesion. The fluorinated oils used are pumped through specially designed manifolds that ensure highly consistent velocity of the fluid.

This oil, of course, stands between the solidifying resin and the tank bottom. The big challenge that the researchers overcame was in the interface between the oil and the resin.

Normally the tank bottom itself provides a perfectly flat surface on which to produce a perfectly flat new printed layer. However, that’s a bit more tricky when you have two liquids interfacing, and one of them is in motion.

The researchers call this interface the “slip boundary”, and evidently they spent considerable effort tuning the system to ensure that the slip boundary is as flat as possible.

3D Printing With HARP

Once in place, they were able to 3D print objects rapidly, as one would expect. However, in order to print faster the power output of the laser must be increased, and thus the temperatures involved were raised.

They found that at 150C the partial prints began to crack. This is a temperature rarely seen in resin 3D printing, so this is understandable: the resins are not designed for this treatment.

However, the circulating oil provided a means to overcome the heat issue. They explain:

“In the case presented here, the accumulation of heat led to surface temperatures in excess of 150°C and the part cracked during the printing process, causing a physical displacement from the stage. Alternatively, the flow of oil dissipated this heat into an oil reservoir. Over time, the temperature of the reservoir increased, reducing its effectiveness. Last, the oil was actively cooled while flowing to help stabilize the reservoir temperature, as well as the surface temperature of the emerging part, at 100° to 120°C.”

This allowed them to run the machine much faster, and this is evident in their sample print video:

HARP Print Speed

Note that this video is sped up by 100x. Still, it is quite impressive. They say they are able to 3D print objects at a rate of at least 431mm per hour. That’s almost half a meter per hour! Their volumetric capacity is a whopping 100L per hour, and they have actually demonstrating printing at this unimaginable rate.

I do have questions about this process relating to resin flow, however. In most “non stick” 3D printing processes, the speed is limited by the viscosity of the resin: as each layer completes, new resin must flow into the space vacated when the layer is raised up. Depending on the dimensions of the layer, this could take a long time or a short time. For spindly objects, it’s typically fast. But for, say, a 3D printed solid brick, it would take quite a while.

In the case of the HARP process, it may be even more challenging, as the flow must occur along the slip boundary. Imagine lifting the “brick” layer: does this cause a bit of a vacuum that distorts the slip boundary? Do they have to wait for it to settle down? It’s not clear.

HARP 3D Printing Advantages

![Sample print emerging from a HARP 3D printer [Source: Science]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d6a52a0e.jpg)

Meanwhile, the HARP process offers a couple of other interesting advantages over alternative methods.

One is that because they are not using an oxygen inhibitor as Carbon does, HARP is able to 3D print resins that react to oxygen. Such materials could not be 3D printed on a Carbon DLS system. On the other hand, how often are such materials required?

Another interesting advantage is that because the oil is continuously flowing, it is able to clean out the build chamber of stray bits of solidified polymer that could otherwise pollute the print and decrease quality.

HARP at this point is mere research, but very promising research indeed. It’s very likely this concept will translate into a commercial venture at some point, where the public might be able to procure HARP-based 3D printers.

Via Science