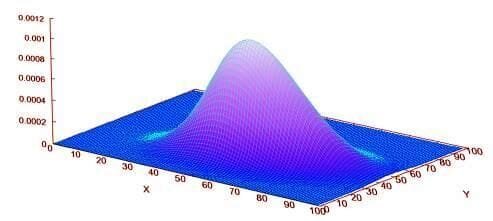

![Bivariate normal distribution [Source: ENGINEERING.com]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08e0e47803.jpg) Bivariate normal distribution [Source: ENGINEERING.com]

Bivariate normal distribution [Source: ENGINEERING.com]

Measurement is often seen as non-value-added work. However, if we properly account for the expected costs involved in passing defects on to customers, then the increased value of the product can be clearly shown.

This approach makes it possible to make rational data-based decisions about when to reduce inspection frequency and how much time and money to spend on metrology. To put it another way, imagine if we didn’t inspect the product and simply sold it without telling anyone that it hadn’t been inspected.

By doing this, we’ve saved the cost of inspection and also reduced the cost of scrap since we won’t reject any of the product if we never inspected it. When we initially stop inspecting, the product would still sell for the same price and so it might seem that inspection doesn’t add any value. However, the uninspected product has a higher probability of failing in service than an inspected product.

A failure is likely to cost the manufacturer money, perhaps due to paying a refund or a concession charge to a major customer. If the failure has major safety or operational importance, then there may be a legal settlement. The failure may also harm the company’s reputation and cause a decline in future sales. I’ve looked at some of these issues before when I discussed how we can go beyond six-sigma in our thinking on quality.

Expected Costs

A key concept to understand when considering the value added by inspection is that of expected costs. An expected cost is a way of accounting for an event that might happen. It is calculated by multiplying the probability of the event occurring, by the cost of the event.

For example, if a defective product is returned for a refund it will cost the manufacturer $10. The probability of the product failing due to a defect is estimated to be 0.2 percent but it has been found that only half of these failures are returned. The probability of a product return resulting in a refund is, therefore, 0.1 percent. Multiplying the cost by the probability gives the expected cost, in this case the expected cost is $0.01.

Combining Defects with Inspection – Conditional Probabilities

The first challenge in quantifying the value added by an inspection process is that it depends on the production process. If the production process is very highly controlled, then very few defective parts will be produced. This means that even if we don’t inspect the final product, there will still be a very low probability of the customer experiencing a product failure.

Actually, the probability of a defect reaching the customer depends on three things: variation in the production process; uncertainty in the measurement process; and how close the acceptance limits are set to the specified limits for the product. If the acceptance limits, or conformance limits, are much tighter than the specification limits, this allows for uncertainty in the measurement and makes it very unlikely that defective products will get past inspection.

However, it also means that more parts will be rejected, many of which actually did conform to the specification. Any change we make to the process will increase cost somewhere:

-

Reducing process variation is likely to require more expensive production machinery or process controls.

-

Reducing measurement uncertainty is likely to require more expensive measurement instrumentation or process controls.

-

Tightening conformance limits will increase the scrap rate.

-

Relaxing any of the above three parameters will increase the probability of defects reaching the customer, increasing the associated expected cost.

These relationships can be most easily understood by considering a simple Monte Carlo simulation. This is a way of simulating random events using random number generators. An event is simulated many times to understand the probability of different outcomes. A simple example would be rolling dice many times and counting how many times different scores are rolled. We will consider the simulation of production and inspection for a part.

Read more at ENGINEERING.com