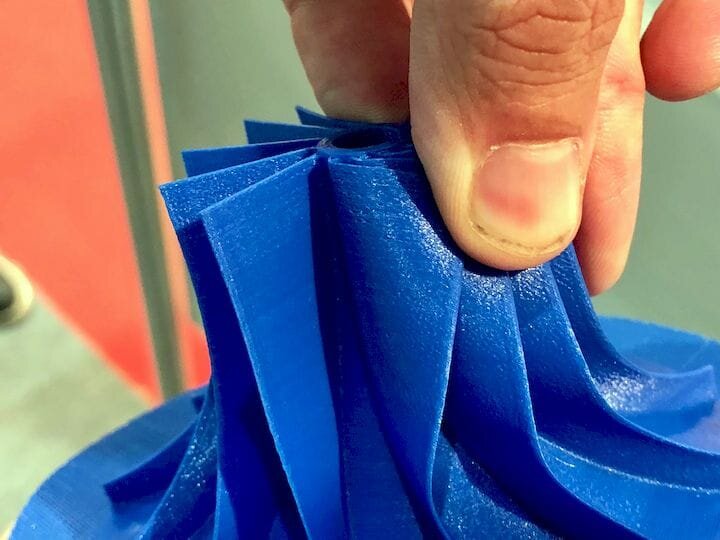

![A flexible TPU 3D print [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08dd525f1c.jpg)

TPU is a great material for a variety of applications.

Thermoplastic Polyurethane is a unique material that can be used in places where the more commonly used 3D printed plastics, such as PLA, are not a good fit. While rubbery, TPU is not rubber, but a thermoplastic. It can be melted down and reused, making it much more eco-friendly than non-recyclable rubber.

TPU is very flexible and highly resistant to abrasion. If you need a product that is flexible, it works very well. Sports equipment, medical devices, and footwear are all excellent products to make with TPU. If you are developing a 3D printing project for students, TPU is a good choice for tires and other flexible parts. There is a significant amount of research going into helmet designs and other high impact protection devices.

TPU Properties

TPU is highly useful for industry where materials are required that resist oil, grease, and solvents.

TPU can be a tough material and should withstand much use before it begins to wear down or lose flexion. TPU sees use for automotive wire jacketing, tires, hoses, gaskets, belts, tubing, and any part that needs flexibility while retaining its shape and strength in the presence of various chemical conditions.

One of TPU’s other notable properties is that it can hold up and function very well in low temperatures. It will maintain its flexibility to a large degree even in cold environments, a strong factor when using TPU for automotive parts.

There are a variety of different versions of TPU. Some versions are highly flexible, able to stretch many times their original length without deformation, making them great for elements that will experience the stress of repeated stretching and compression.

TPU also can be dyed in a wide variety of colors, leading to increased use in sneaker soles. Adidas has begun using TPU to get tough, flexible sneakers that are both more comfortable and provide better performance.

With so many factors to recommend it, you’d think TPU would see widespread use in places where rubber is currently used. Unfortunately, TPU is not very easy to work with as most TPU parts are currently made via injection molding. Sometimes TPU is machined, but this is not ideal and there are risks of shrinking and warping using these methods.

3D Printing TPU

3D printing is a great answer to these issues.

With 3D printing, it is possible to achieve more precision and less warping. It opens up new possibilities, particularly in fields like medical devices where precise customization is vital.

However, TPU tends to blob during the 3D printing process as it tends to have issues bridging. Getting the print speed and the right printer is absolutely necessary to getting good results when printing with TPU.

Many manufacturers print TPU using FFF printers, where TPU material in filament form is fed through an extruder for deposition.

A look at the strengths and weaknesses of FFF and SLS 3D printing with TPU:

FFF’s TPU Strengths

-

Simple post-processing

-

Affordable pricing and cost-effective

-

Quick iteration

-

Wide range of materials available

FFF’s TPU Weaknesses

-

Low dimensional accuracy

-

Low resolution

-

Part strength and real world usability is low

SLS’s TPU Strengths

-

Increased printing accuracy

-

High detail

-

Smooth surfaces

-

High abrasion and wear resistance

-

Affordable cost per part

-

Wide range of materials available

-

Isotropic mechanical properties

-

Un-sintered powders act as a support, reducing negative draft and interior features problems

-

Feasible for multiple pieces of small sizes with complicated geometry

SLS’s TPU Weaknesses

-

Thin walls in large models may warp after cooling down; parts with thin walls may not be printed due to the minimum 1mm limitation

-

Parts are printed white (but can be dyed different colors)

If you are looking to build a product that has the kind of flexibility that TPU offers, we recommend exploring your options.

The best methods for 3D printing TPU in the most efficient and effective way possible is probably using the SLS 3D printing process. Our source for this information was from Jawstec, you can contact them today for a free quote.

Via Jawstec