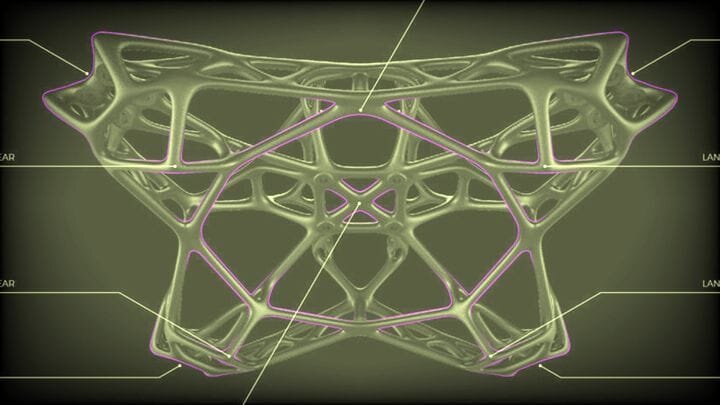

![The 3D printed Helyx drone was made using generative design [Source: SolidSmack]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08daf434bb.jpg) The 3D printed Helyx drone was made using generative design [Source: SolidSmack]

The 3D printed Helyx drone was made using generative design [Source: SolidSmack]

It wasn’t too long ago when the concept of unmanned aerial vehicles (UAVs) and the capabilities of generative design seemed like some far off sci-fi future.

Yet, both technologies are alive and kicking in 2019—and they came together recently to test the implementation of generative design and additive manufacturing capabilities in the field of UAVs.

The Helyx Drone, from Italian design and manufacturing company Sigma Ingegneria, focuses on the development of a First Person View (FPV) drone for racing and freestyle applications.

Created using Autodesk Fusion 360 (and seen here rendered in Keyshot), the design process took into account three key factors that are fundamental to the development of an FPV chassis: reduced air resistance, reduced weight, and capability of withstanding impacts.

![Main features of the 3D printed Helyx drone [Source: SoldiSmack]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08daf8d2dc.jpg)

While the primary purpose of the drone is to test the implementation of generative design and additive manufacturing in the field of UAVs, the Helyx isn’t a slouch when it comes to speed. It can go from 0-100 km/h in just 1.2 seconds and reach speeds of up to 208km/h, making it ideal as a racing and freestyle drone. These insane speeds can be achieved thanks to the drone’s unique geometry, which is meant to distribute the g-forces and weight of the drone evenly.

![Bottom view of the 3D printed Helyx drone [Source: SoldiSmack]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08dafdd419.jpg)

Much of Helyx’s uniqueness stems from its web-like cage design—which heavily utilizes the capabilities of generative design and additive manufacturing. Apart from evenly distributing 87.5 grams of weight, the cage also reduces air resistance and allows the drone to withstand strong impacts – something a drone needs when moving at such high speeds.

Read the rest at SolidSmack