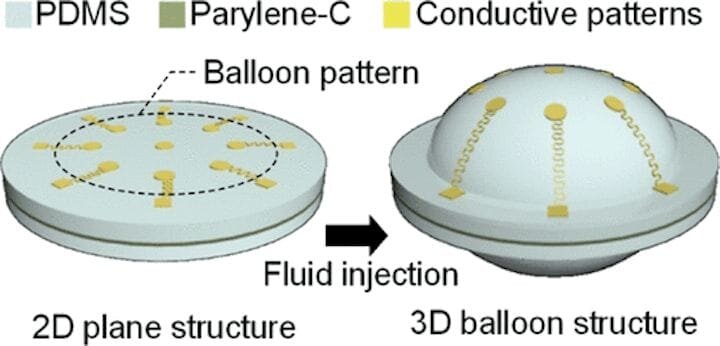

![Balloon 3D printing concept [Source: ACS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08dea3f0b3.jpg) Balloon 3D printing concept [Source: ACS]

Balloon 3D printing concept [Source: ACS]

I’m reading a research paper that uses an unusual technique to create 3D shapes — using balloons

The research, performed by scientists at the Daegu Gyeongbuk Institute of Science and Technology in South Korea, has developed a form of 3D printing I have not seen previously. Their approach is specifically designed for the production of three-dimensional small electronic devices, but I suspect it could be used for other purposes, too.

MEMS Printing

The idea here is that it is difficult to print in three dimensions, as compared to the conventional manner of 2D printing on flat surfaces. 3D is just much more complex, as readers of this publication will certainly attest.

The researchers sought a way to more easily produce small electronic devices for human implantation — devices that are not easily produced using the conventional MEMS process.

MEMS, or Micro-Electro-Mechanical Systems, is a well-known process for the production of tiny micro machines that involve both mechanical and electronically elements. It’s typically used to make sensors, and sometimes arrays of components that join together to form a larger functions.

Balloon Layer 3D Printing

The normal process for MEMS is to deposit multiple tiny layers of differing material to build up an object, just like larger-scale 3D printing works. However, the researchers say:

“Three-dimensional (3D) structures composed of flexible and soft materials have been in demand for implantable biomedical devices. However, the fabrication of 3D structures using microelectromechanical system (MEMS) techniques has limitations in terms of the materials and the scale of the structures.”

Those limitations spurred them to develop a new technique that surprisingly uses balloons as a key part of the process.

Their technique involves using laminated layers of material. However, the trick here is to not provide adhesion in all parts of the layers and instead introduce air into a portion of the space between layers. This causes the overall structure to bulge, creating the necessary 3D form.

Of course, the electronic patterns would have been previously printed in 2D upon the top layer. When “bulged”, they continue to provide the function in 3D form, yet were created using 2D methods.

Large-Scale Balloon 3D Printing?

This is a very unusual approach that I haven’t seen elsewhere. While it appears to work for tiny devices with the materials used by the experimenters, I’m wondering whether the “balloon” approach could be used in other types of 3D printing.

Imagine a 3D printer that printed an object in a new semi-solid form material, to be cured to solid form after printing. While in a semi-solid state, air could be introduced at appropriate points to very quickly create 3D structures that would otherwise take potentially hours to build.

Obviously there would be countless challenges in making such a system. What exactly would this unusual semi-solid material be? How would be be cured after printing? Would it have to be cured during 3D printing?

What about the complex software needed to analyze a 3D model and generate the necessary balloon segments required to be inserted into the print periodically?

It may be there is some additional research to be undertaken here.

Via ACS