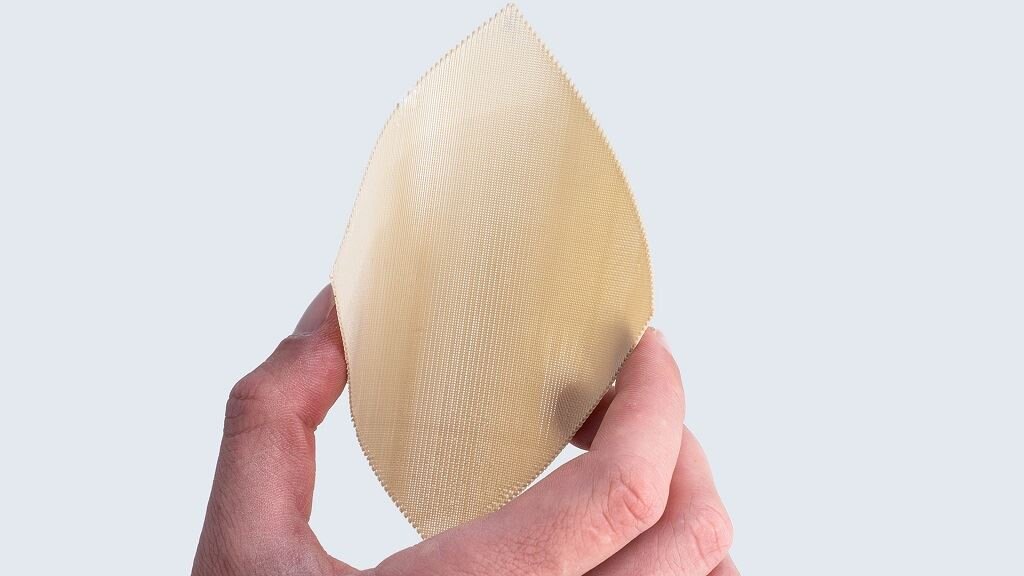

![3D printed PEEK implant [Image: Kumovis]](https://fabbaloo.com/wp-content/uploads/2020/05/additively_manufactured_peek_implant1_img_5eb08f659890c.jpg) 3D printed PEEK implant [Image: Kumovis]

3D printed PEEK implant [Image: Kumovis]

We recently caught up with Munich-based Kumovis for a conversation in medical 3D printing for production.

Stefan Leonhardt is one of two Managing Partners and four Founders of the young company, driving efforts since Kumovis planted its roots in 2015.

Founding Kumovis

![Kumovis’ founders [Image: Kumovis]](https://fabbaloo.com/wp-content/uploads/2020/05/kumovis_3d_printing_company_founders1_img_5eb08f65e3408.jpg) Kumovis’ founders [Image: Kumovis]

Kumovis’ founders [Image: Kumovis]

Founded during the co-founders’ tenure earning doctoral and master’s degrees at the Technical University of Munich (TUM), Kumovis was born from the idea of 3D printing high-performance materials for medical use.

“We were familiar with PEEK from injection molding and compounding, as a certified material for certified medical implants. When we were looking, there were really no machines to 3D print for this. With our first prototype we were at a small fair in 2016 with small 3D printed PEEK samples and the feedback was so good we decided to go on with that,” he explained.

The German-funded EXIST Grant from the European Social Fund paved the way for 18 more months of work at the university, during which the team’s aim was to develop a market-ready prototype. In December 2018, Kumovis closed a €1.2 million seed round with investors.

And this August, the Kumovis R1 clean-room-capable 3D printer came to market.

Kumovis currently has a staff of 11 full-time employees with 5 students contributing to the team. The early ties with TUM have only deepened, and Leonhardt noted that “we always have five or six students here who are working on their bachelor’s or master’s thesis.”

Point-Of-Care 3D Printing

![The R1 3D printer [Image: Kumovis]](https://fabbaloo.com/wp-content/uploads/2020/05/kumovis_r1_3d_printing_platform_front1_img_5eb08f663cc33.jpg)

The team is constantly in close contact with those who will benefit most from the R1’s technological capabilities — medical companies, contract manufacturers, and medical and dental clinics.

“The idea is to bring the technology to exactly where it is needed, as a point-of-care technology, to place directly in a hospital, for example,” Leonhardt said. “Most use cases today are in bone reconstruction, such as jawbone reconstruction, or in dental implants.”

The Kumovis R1 is equipped to handle several advanced materials approved for medical use. The team is focusing squarely on medical, rather than broadening usage to encompass industry applications as well.

“We designed the machine from day one to be used for medical production,” Leonhardt noted. “It is not just for prototyping or work just in a lab, but for production, and even large-scale production.”

Among the materials usable with the R1 are:

-

Implant-grade PEEK

-

Degradable materials

-

PPSU, currently approved for in-the-body use for 30 days and planned to be implant-grade by the end of the year

-

ULTEM, approved for 30-day use inside the body

-

Medical polycarbonate

-

Medical HDPE

-

Medical-grade polyamide for dental implants

And by the end of the year, the goal is to add implant-grade PEKK for use in spinal applications.

The expanding materials list shows a few things about the company’s strategy: first, they are forward-thinking and aware of the needs of their target customer demographics. Second, they are working very closely with the chemistry industry to interact with polymer producers directly.

“In the next year, we could double the implant- or medical-grade materials,” Leonhardt said. “We have process parameters for all of the materials here.”

The 3D printer itself can be tuned in to these materials, ensuring appropriate temperature and other necessary environmental controls.

“We integrate a clean room into our printer, which is especially interesting to smaller companies and labs which do not have a clean room — now they have this environment inside the machine,” he added.

Ensuring that prints are in no way contaminated by their environment is vital for any product that will come into contact with the human body. It is especially critical for those are designed to degrade in the body over time, as anything embedded in any part of the print will loosen: “So we have to ensure that during the printing process there is no contamination.”

The ultimate point of point-of-care 3D printing is, of course, usability, and the team at Kumovis kept that in mind throughout the entire design process. The machine’s components, for example, are made of easily-cleanable stainless steel.

“The machine should not be used only for publication or to write some papers: it should be used to bring new products to patients where we think it could help them,” Leonhardt said.

Customers and Pricing

![An impression tray, part of the digital workflow process [Image: Kumovis]](https://fabbaloo.com/wp-content/uploads/2020/05/kumovis_digital_workflow_impression_tray1_img_5eb08f66c3a16.jpg)

Kumovis is working with medical and dental companies in a deeply interconnected ecosystem.

Part of this comes to Kumovis’ pricing structure, in which rather than a customer flat-out buying a 3D printer and only getting in touch for materials or service needs, a revenue share system ensures an ongoing relationship.

“We don’t see ourselves as just a machine supplier, that’s not what we want. We want to supply the customer with a full solution,” Leonhardt explained. “We have customers we are working with on revenue shares: we help in setting up the process, supplying the materials, designing the implants, also how to get the print out of the machine, then how to post-process. Then we get a revenue from the final product. It’s an interesting model for smaller companies, they don’t have this high initial investment cost. We really saw that it’s not the right solution to just give the customer a printer and say, ‘Now you can work by yourself.’ It’s a new technology and they need help, that’s why we have this business model.”

In Kumovis’ home base of Germany, most medical companies are these small enterprises, employing 5-15 people, Leonhardt added, giving more context to the regular reference to work with smaller entities.

Hospitals and clinics directly in point-of-care use are also very important to Kumovis’ operations, especially with medical 3D printing requiring so much more in the way of regulatory establishment.

Shortening the supply chain that now encompasses a surgeon, the patient, and a medical product producer to more quickly and immediately bring effective solutions directly to the patient would help speed up treatment and healing times with fully personalized solutions.

Importantly, and in keeping with so many touted applications of 3D printing for localized production, is overall price reduction versus conventional solutions.

Leonhardt pointed to the example of a cranial implant.

“Cranial implants are now machined out of a full block of material. For example, an implant with a weight of 14g is created out of full blocks that see 186g of material thrown away. We produce the same product with 21g of material. You save a lot of money just by reducing the material waste, and this makes it interesting also from a sustainability point of view. Materials are normally very, very expensive, perhaps €2-3,000 for a kilogram of implant-grade material, and if you throw away so much, it is very costly. This is one big way of reducing costs, just reducing the material,” he said.

“In another way, it is easier to work with a 3D printer than a milling process. 3D printing can directly go into the workflow: use software and design it, work exactly with this data set. One person could easily work with several printers, reducing labor and personnel costs.

“Then look a bit wider, into the full ecosystem of the medical environment. Surgical guides for jaw reconstruction…can save up to 150 minutes of operation time, which saves a lot of money and patient operation time too. Customized implants are better implants, as patients can stay less time in the hospital.”

Production-ready 3D printing has a long way to go yet, with regulatory clearance still in the works across the globe and medical suppliers and providers still becoming familiar with the technology. But one thing is clear from speaking with Kumovis: it is also very much a reality today. The R1 clean-room-capable 3D printer is on the market now.

Via Kumovis