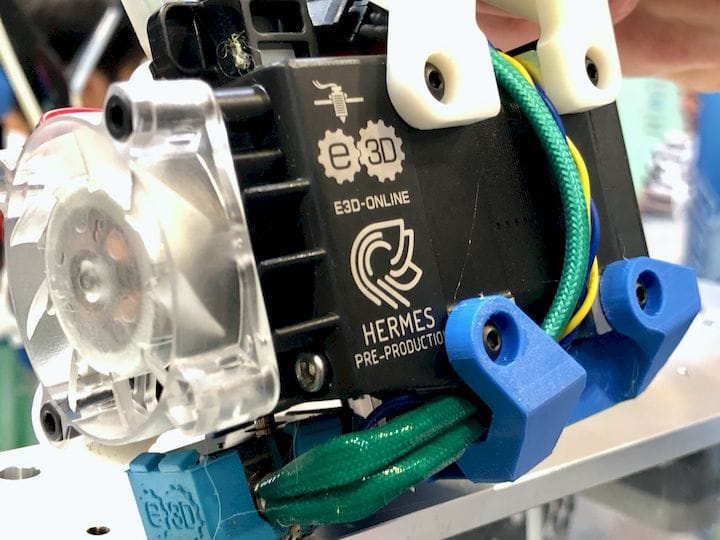

![E3D-Online’s new Hermes system [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/hermes-label-1_img_5eb08faf832f5.jpg) E3D-Online’s new Hermes system [Source: Fabbaloo]

E3D-Online’s new Hermes system [Source: Fabbaloo]

E3D-Online announced a brand new extrusion system, the Hermes.

E3D Popularity

![Selection of hot end nozzles for E3D’s hot end systems [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08fafead6c.jpg) Selection of hot end nozzles for E3D’s hot end systems [Source: Fabbaloo]

Selection of hot end nozzles for E3D’s hot end systems [Source: Fabbaloo]

The UK-based firm has become the gold standard for key 3D printer components, producing well-regarded hot ends, extruders and other important parts. Their offerings have made their way into countless 3D printers made by not only hobbyists, but more importantly many of the leading 3D printer manufacturers, including Kodak, Prusa Research, LulzBot and others.

Even if you do not intend on buying a Hermes extruder for your DIY system, it is quite likely you will eventually end up using one that’s embedded in a pre-built system from another manufacturer.

![Some of E3D’s older, but still very popular, hot end products [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08fb03aa71.jpg) Some of E3D’s older, but still very popular, hot end products [Source: Fabbaloo]

Some of E3D’s older, but still very popular, hot end products [Source: Fabbaloo]

The company’s flagship extruder has been the Titan series, and the V6 hot end, but now the Hermes takes a bit of a different path. It’s not an evolution of a previous product, and seems to be all new from the ground up.

Hermes Extruder and Hot End

It’s a combination of hot end and extruder all built into a single unit. Virtually all other systems separate the two functions into separate components: one to push the filament (the extruder) and the other to heat the filament (the hot end). The Hermes is actually both.

How do they do this? It’s derived from some clever engineering, and actually removing structures found on traditional extruder / hot end designs.

Hermes Direct Mount

![Side view of E3D’s new Hermes system [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08fb075473.jpg) Side view of E3D’s new Hermes system [Source: Fabbaloo]

Side view of E3D’s new Hermes system [Source: Fabbaloo]

For example, the heat sink directly mounts on a NEMA 17 stepper motor, the default device for powering extruders. This eliminates a bunch of structure that would normally hold the two together.

The drive wheels push the filament directly into the heatbreak, eliminating the typical gap found on traditional designs. That gap is in fact where many extrusion problems occur: twisty filament bends while traversing the gap, and then misses the heatbreak entry hole, for example.

Hermes Flexible Filament

That gap is also the main challenge when 3D printing flexible filament. The usual problem is that the spaghetti-like filament simply can’t be pushed across that gap, especially at speed. Usually flexible filament 3D printing works only when done very slowly. With the Hermes, this is not the case.

In fact, an E3D representative told me:

“You can print flexible filament just like PLA.”

Wow, that is a game-changer! Many 3D printer operators have avoided flexible materials due to the complexity — and frustration — in attempting to print with it. That might all change with the new Hermes system.

Hermes Extruder Features

There’s several other very interesting characteristics about the Hermes:

-

It includes dual drive wheels to ensure a firm grip on any filament

-

It’s designed for maximum integratability with many 3D printer designs

-

It can be completely assembled offline

-

The materials used in the Hermes mean there is no requirement for lubrication

There’s one other really important feature on the Hermes: manufacturing.

Hermes Mass Manufacturing

E3D’s prior products have been produced with CNC milling processes. The Hermes components (well, some of them) will be produced using die cast processes. This produces highly reliable parts and dramatically lowers the costs, as die casting can mass produce items more quickly than milling.

In fact, the entire Hermes system has been designed to be mass manufactured. The result of this is that although the system offers vastly improved extrusion performance, the costs are kept low.

Hermes Pricing

![E3D’s new Hermes system installed on their 4-material tool changing 3D printer, which is now shipping to the public [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/hermes-tool-changer-1_img_5eb08fb0bd36c.jpg) E3D’s new Hermes system installed on their 4-material tool changing 3D printer, which is now shipping to the public [Source: Fabbaloo]

E3D’s new Hermes system installed on their 4-material tool changing 3D printer, which is now shipping to the public [Source: Fabbaloo]

E3D tells me that they hope to launch the Hermes in November, and it will be priced at under £100 (US$123).

Let’s wait six months and see how this affects the 3D printer market. There should be some very interesting machines emerge with these new capabilities. Expect to see a lot more flexible filament-capable devices very soon.

Via E3D-Online