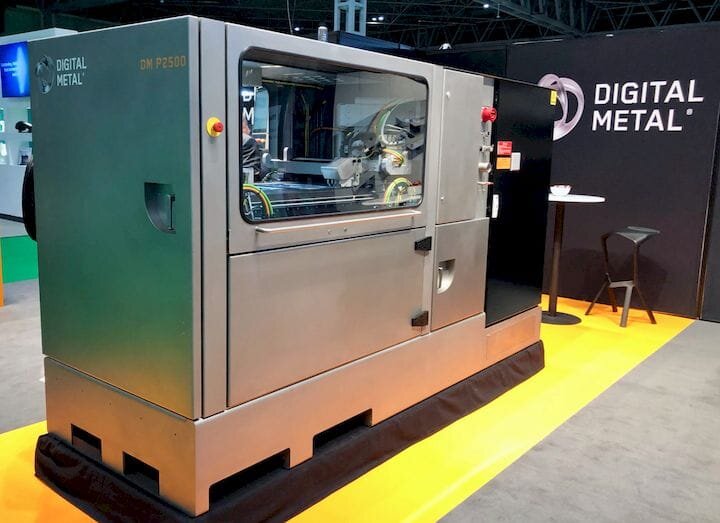

![Digital Metal’s DM P2500 metal 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/digital-metal-printer-128129_img_5eb08fcc82199.jpg)

Digital Metal is one of our favorite additive manufacturing companies.

They produce a device that 3D prints in metal, but not using the more typical powder bed-laser combination. Instead they use a cold binder jet process.

Binder Jet Metal 3D Printing

In their process very fine inkjets selectively deposit binder on a level powder bed. After a new powder layer is recoated on top, the next layer is selectively bound with the binder.

The loose powder is then removed, and the fragile, but solid object is processed. First, the binder is removed, leaving only the metal particles. Then this object is heated to a level where the particles sinter together to form a solid metal object.

Digital Metal’s DM P2500

The notable aspect of Digital Metal’s DM P2500 (seen at top) is that the resolution of their prints is simply astounding. We’ve written about this previously, but I am always amazed to see their prints. Not only are the objects startlingly small and full of details, but usually when you look very, very closely you can see logos and text written at even smaller levels.

Accordingly, their 3D print process uses a rather small build volume, since highly detailed objects are typically not large. Their earlier machine model had a build area of 110 x 110 mm.

However, we’ve learned that the company has quietly upped their maximum build volume, as it is now 203 x 180 mm, with a maximum height of 69mm.

Large Metal 3D Print

![Large 150 x 150 mm metal 3D print made by Digital Metal [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/digital-metal-150-1_img_5eb08fccabeb3.jpg)

Here you can see a fully solid metal print of these dimensions. I picked this one up, and yes, it was quite heavy.

Here’s a side view of this large metal 3D print. Note the exceptionally good quality of the edges and overhangs. This is due to their powder printing process, which evidently can scale to at least this size.

![Large 150 x 150 mm metal 3D print made by Digital Metal [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/digital-metal-150-detail-1_img_5eb08fccce0c0.jpg)

I should point out that this object has not been finished in any way, other than normal powder removal from the printer. It’s very smooth!

Large Metal Build Volume

The boost to 150mm is notable, but not amazing. But here’s the interesting part: Digital Metal believes their process is scalable and could theoretically be made even larger.

How much larger, exactly? They won’t say. However, since this is a powder bed system, I would speculate that Digital Metal could make the bed far larger if required. If the post-processing works at 30mm height, there should not be a strong limit to the widths.

As for the Z-height, that’s another story. I don’t know how their post-processing works, and so there may be limits to the height. Nevertheless, we could in the future have another option for larger metal 3D prints, one that offers spectacular surface quality and likely a far lower operational cost.

Via Digital Metal