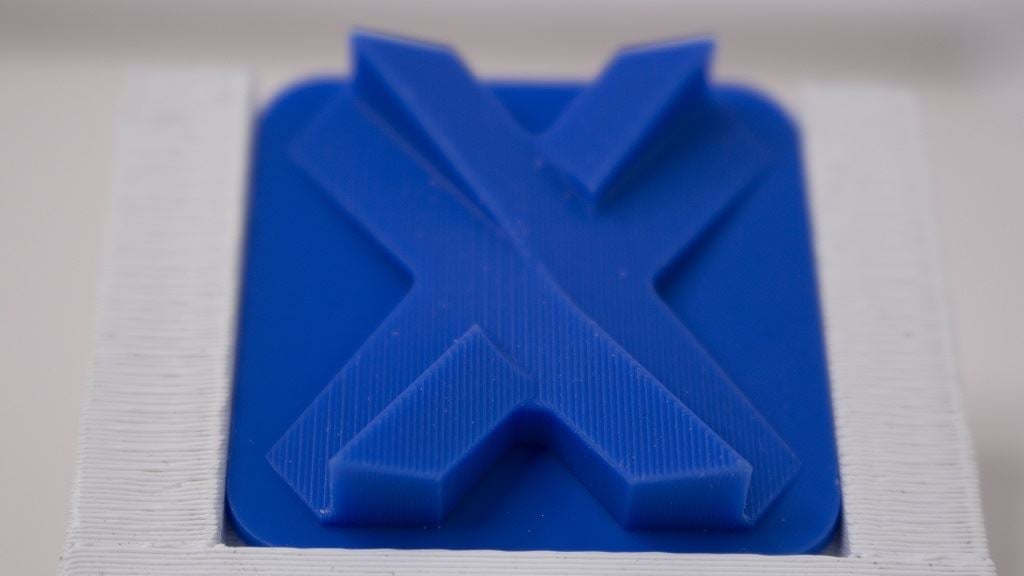

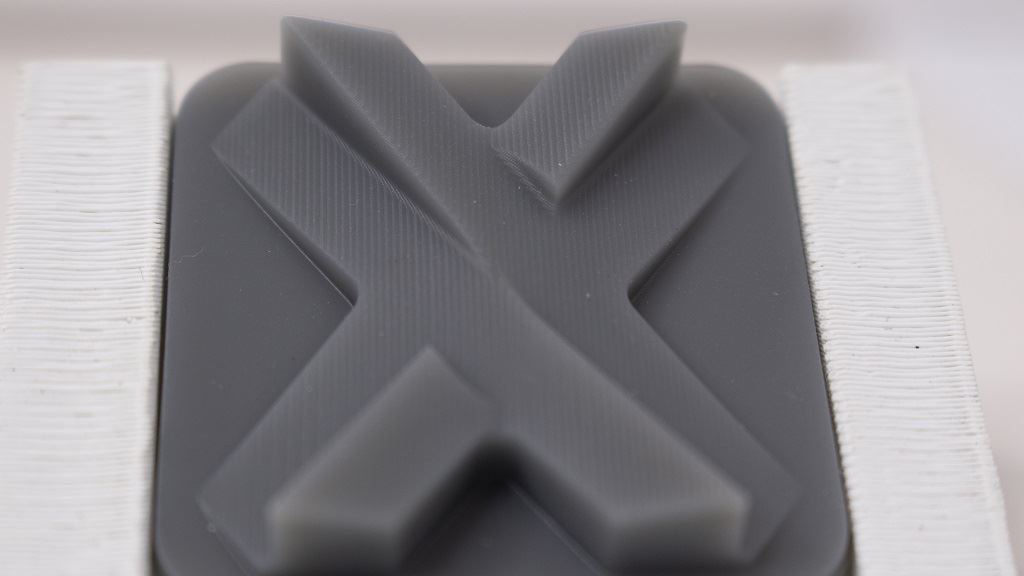

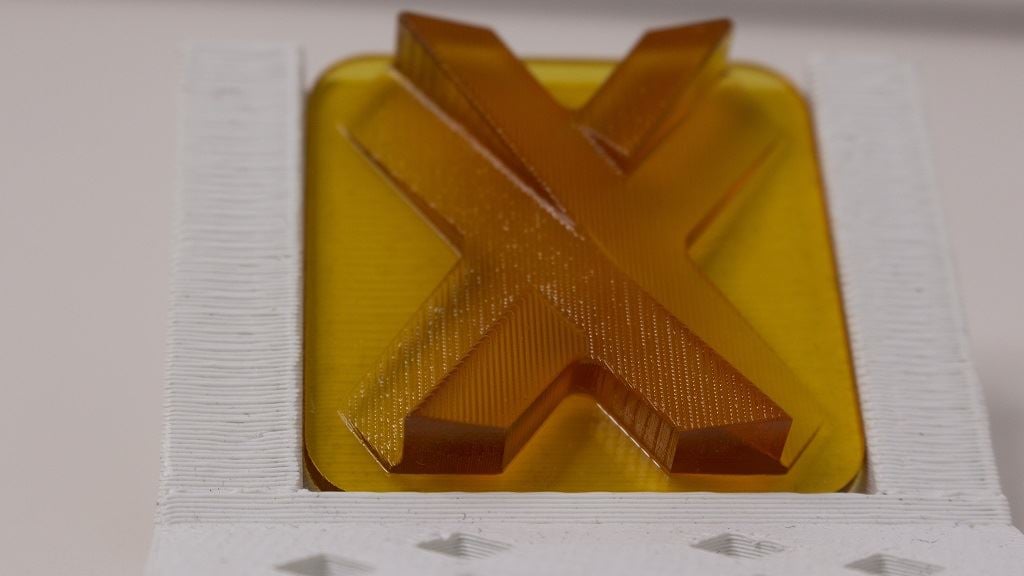

![Carbon DLS 3D printing via Xometry [Image: Xometry]](https://fabbaloo.com/wp-content/uploads/2020/05/xometrydlshighperformance_img_5eb092a5d50b9.jpg)

On-demand manufacturing platform Xometry now offers Carbon’s Digital Light Synthesis 3D printing technology.

The announcement puts DLS alongside existing 3D printing processes available through the platform:

-

HP’s Multi Jet Fusion (MJF)

-

Selective Laser Sintering (SLS)

-

Stereolithography (SLA)

-

Fused Deposition Modeling (FDM)

-

Direct Metal Laser Sintering (DMLS)

-

PolyJet

The Right Tech For The Job

As they continue to add more manufacturing processes, Xometry is both responding to customer demand and perhaps making the choice more difficult for customers who might not yet know exactly what they need. As such, they continue to offer educational resources to help guide decisions, such as a video series on how to select the best 3D printing technology.

All of the available technologies, now including DLS, are accessible through Xometry’s expansive — 3,000+ — partner manufacturing network.

Customers looking to have a part or parts made can use the Xometry Instant Quoting Engine to receive an instant quote, design feedback, and lead time for manufacturing via the process of their choice.

Along with 3D printing, Xometry offers CNC machining, sheet metal fabrication, injection molding, die casting, stamping, extrusion, and urethane casting.

Adding DLS

With all those capabilities and technologies, why bring in another option — and why specifically Carbon’s DLS?

The process has drawn great attention — and investment — since Carbon first introduced its super-speedy 3D printing process to the market a few years ago. That company has not slowed down its own pace, either, introducing new hardware, software, and materials to further make its 3D printing offerings appealing. And it’s working: people want it.

So I asked the Xometry team why they would bring Carbon into operations. What makes it stand out?

“Carbon DLS is one of the most advanced 3D printing technologies available. It gives engineers the ability to make 3D printed parts with end-use durability, resolution and surface finish. With a heavy focus on materials development, Carbon is bridging the gap between prototyping and production,” Tommy Lynch, Senior Applications Engineer at Xometry, tells Fabbaloo.

Through Xometry, customers looking to obtain parts made with DLS have some variety in material options, including:

-

General Purpose

-

UMA 90 (Urethane Methacrylate)

-

FPU 50 (Flexible Polyurethane)

-

-

High Performance

-

EPX 82 (Epoxy)

-

CE 221 (Cyanate Ester)

-

RPU 70 (Rigid Polyurethane)

-

-

Elastomers

-

SIL 30 (Silicone)

-

EPU 40 (Elastomeric Polyurethane)

-

These material options go some way in explaining the demand for DLS, as they offer a variety of levels of performance for both prototype and end-use parts.

Xometry has been looking into the possibility of adding Carbon’s capabilities to its portfolio for some time, and let us know that their customers have also been requesting it. Their recent investment round has helped to take the step forward with another additive manufacturing technology.

I asked why their customers wanted this addition:

“Carbon is an exciting, industry-leading company that many of our customers follow closely. DLS technology is filling a void, particularly in short run production. Customers now have the option to make highly intricate parts, with materials engineered to specific performance characteristics(i.e. hi-temperature, chemical resistance, impact strength, elastomers). Historically, hard tooling for injection molding may have been cost prohibitive for short runs, and traditional printing technologies were lacking in durability, resolution, or performance. Carbon has done an excellent job of combining these performance materials with an innovative build process, to give engineers yet another tool to compress cost and lead time associated with new product design,” Lynch tell us.

Given that perspective, the team are anticipating great interest in their latest offering:

“We expect strong demand for DLS, and anticipate that this demand will grow as customers continue rapidly adopting additive manufacturing as a production solution,” Aaron Lichtig, Vice President, Growth Marketing, tells us.

Obtaining access to DLS can be enticing, but not always easy for interested new users. Going through a service company like Xometry allows for use without the investment into Carbon’s 3D printer leasing program, with immediate access to operators and engineers familiar with the platform.

Via Xometry

MakerOS has a brilliant hidden feature in their online service: a sophisticated 3D print pricing calculator that allows operators to determine exactly how to price prints.