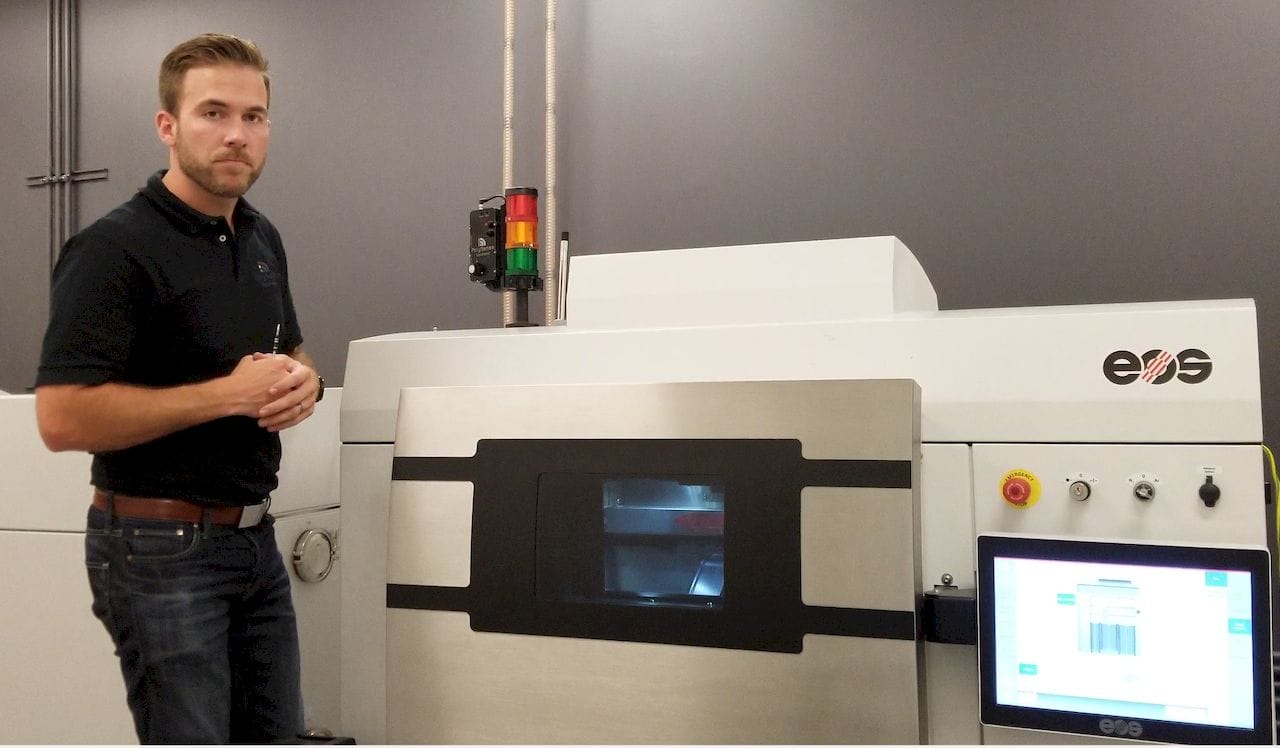

![Matthew Gale showing a real-time sensor installed on an EOS metal 3D printer [Source: Polysense Solutions]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0917135a71.jpg)

I’m looking at a very intriguing device for 3D printers from Polysense Solutions.

The Winnipeg-based startup company has developed a specialized sensor system that can detect 3D print failures in real time, able to alert operators who can take immediate action. This sophisticated device, in some operational scenarios, could save thousands of dollars of wasted 3D print time — and in some cases help retain happier clients.

I strongly suspect any site operating a fleet of metal 3D printers will be extremely interested in this offering.

![Polysense Solutions sensors installed on EOS metal 3D printers [Source: Polysense Solutions]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09171a71db.jpg)

Fabbaloo: What is the issue PolySense Solutions is attempting to solve?

Matthew Gale: “There are many pieces of equipment out there that have long unattended process times. An example is 3D printers, wire EDMs, lab testing equipment like load frames and orthopedic testing machines. These processes can run for many hours, sometimes days at a time to produce the desired parts or test result. When failures occur they can be very costly, especially over night or on the weekend when there are no personnel around to repair or restart the process.

Our goal is to predict these failures before they occur, or at the very least send a notification when the failure does occur, this way the right people can respond in order to get the process up and running again. This keeps turnaround time, labor and costs low for our customers.

Monitoring equipment utilization, failure root cause, and maintenance scheduling is usually spread over multiple pieces of software, or kept track of on someone’s computer with a spreadsheet. We wanted to put all of this into one place on our web application that can be accessed on any device, anywhere. This helps our customers make better evidence based decisions because they have easy access to their data in one place.”

![Real time activity sensor installed on a metal 3D printer [Source: Polysense Solutions]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09172165c1.jpg)

Fabbaloo: What led you to starting PolySense Solutions? Was there not a product on the market to perform this function already?

Matthew Gale: “It started when I received a request from an orthopedic testing lab to develop a method of notifying staff when their laboratory equipment experienced a failure, specifically over the weekend when staff was not present. When this equipment went down on a weekend, and was not restarted until Monday, it would result in thousands of dollars lost in testing time. I came up with a simple device to email and text staff when the equipment went down so they could come in and get it up and running again asap.

Because of the success of this device, I was asked to do the same thing for a local additive manufacturing company. They own 4 EOS M290 Direct Metal Laser Sintering machines, and were experiencing similar issues as the testing company. They had long build times, sometimes lasting several days. It was not uncommon for a build to fail over the weekend and lose 2 days of print time, and be 2 days late getting the parts to the customer. This would also result in having to spend a lot of time and money restarting the failed build.

I’ve heard of other companies who own these DMLS machines using windows remote desktop to login to their machines computer to view the status of them, but this requires the staff member remembering to do it, as well as introducing some security vulnerabilities with this method. I do not know of any other competitor that can provide the same product/service as we do.

The closest competitor would be data logger companies that have the ability to sense certain things like light, vibration etc, but most of the ones I am aware of would be very complicated to setup to accomplish the same tasks as our product.

A large benefit of using our product over something like a datalogger is our web application that allows our customers to keep all of their quality assurance data in one place. Things like raw material suppliers, lot numbers, personnel involved in setting up and programming the equipment, are all tracked for each build. This information can be viewed on any device.”

![Dashboard showing metal 3D printers connected to monitoring network [Source: Polysense Solutions]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0917262c51.jpg)

Fabbaloo: Without giving away any secrets, how does the product work? What would a customer expect to experience?

Matthew Gale: “It only takes about 10 minutes to install and setup because it does not require any wiring or electrical connections to the equipment it is monitoring.

With respect to the DMLS machines we use a series of light and vibration sensors to detect when the machine is building. If the machine stops building unexpectedly it will email/text anyone who has notifications enabled on our web application. It also will let staff know when the build finishes successfully.

Another great Feature is that It will monitor the recoater system and can analyze and record each recoat. Using our algorithm, it will determine if the recoat is normal, or abnormal. If the recoat was abnormal, personnel will be notified so they can hopefully get to the machine quickly enough to solve the issue causing the abnormal recoats and potentially salvage the build. Recoater related issues are a large contributor to DMLS build failures, but the build can be salvaged if someone is alerted in time, and can take action.”

![Data for a specific metal 3D printing job shown in web interface [Source: Polysense Solutions]](https://fabbaloo.com/wp-content/uploads/2020/05/polysense-job-data_img_5eb09172ce76d.jpg)

Fabbaloo: Who should be using this type of product? What is your target market? Is it only for 3D printing, or are other machine types possible?

Matthew Gale: “Currently our target market is primarily owners of EOS DMLS machines like the M270,M280,M290 and M400.

However we are now testing our device on other equipment like wire EDMs, load frames, molding equipment, and really anything that needs monitoring while it runs unattended. We can measure visible and infrared light, ambient temperature/humidity, surface temperature, fluid temperature, vibration, proximity, and rotation to customize a solution for hopefully any customer.”

![Chart of recoater feedback for a real time monitoring system [Source: Polysense Solutions]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0917344bf8.jpg)

Fabbaloo: How did you go about developing the product? How long did it take to do, and were there several iterations? Were you able to test it in a live 3D print workshop? Do you have an existing client base today?

Matthew Gale: “The very first version was based on an Arduino micro-controller and just simply sent a message to a list of emails when it thought the machine was on or off. It worked, but it would sometimes mistakenly send emails from time to time, and did not have anyway for users to login to anything to change notifications, add/remove emails etc.

So several iterations later (I lost count), and approximately 1.5 years later, I have the current version. I have 4 of them being used at Precision ADM here in Winnipeg, which is an AS9100 and ISO 13485 facility, meaning they have the approved quality systems in place to manufacture aerospace and medical components. They really like our product, and because they were our beta testing site, they were a key driver in many of the features we have added. We are now looking to increase our customer base.”

Fabbaloo: Is the product available now? What is the price level?

Matthew Gale: “Our product is available for pre-order right now on our website. We will be fulfilling orders in late September. We will be offering a one month free trial with the device(s) and access to the web application. Head over to our website where you can get in touch with us to talk about our plans and pricing.”

Fabbaloo: What regions are you selling to, and how does one make a purchase? Do you have a reseller network or distributors?

Matthew Gale: “Currently we are selling to only Canadian customers until we complete our certifications to sell internationally. Our hope is to have this complete by end of 2019. International customers can definitely pre-order, and we will keep them posted on shipping dates.

We are working on accepting credit cards on our website, but currently only accept cheque or credit card via PayPal.”

Fabbaloo: Today you have one product, do you expect to be making additional items in the future? Could you hint at what they might do?

Matthew Gale: “Currently our product works with EOS DMLS machines, and certain Wire EDMS. Our monitoring device has the ability to measure visible and infrared light, ambient temperature/humidity, surface temperature, fluid temperature, vibration, proximity, and rotation to customize a solution for hopefully any customer.”

All of these sensors are used to determine the status of a piece of equipment. Our plan for the future is to continue to add more sensors and solutions so that our device can be used in virtually any environment.

Via Polysense Solutions

An Austrian company has developed an incredibly sophisticated end-to-end automation system for metal 3D print post processing.