![The Airwolf 3D EVO R 3D printer, ideal for advanced education [Source: Airwolf 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0923ca7e69.jpg)

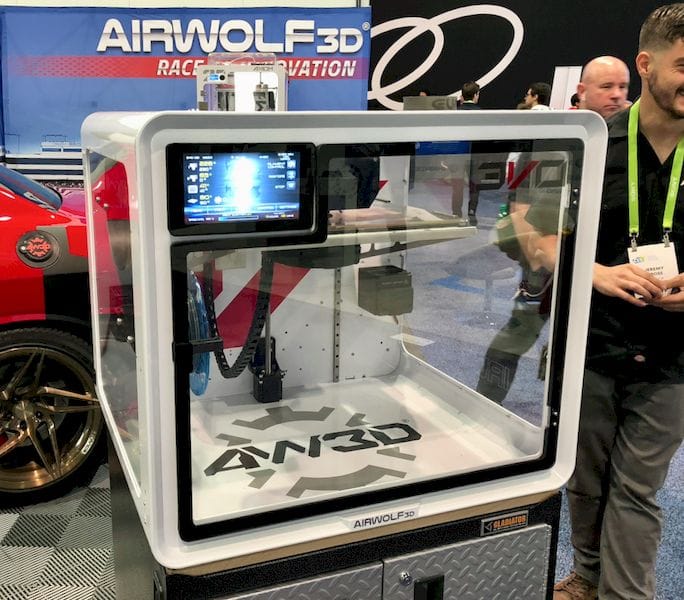

Airwolf 3D announced a new and very powerful desktop 3D printer today, the EVO R.

The California-based company has been producing industrial 3D printers for quite a few years, announcing increasingly powerful devices sporting a wealth of convenience features. Their most recent device releases were the EVO line, which the company terms as an “Additive Manufacturing Center”.

The original Airwolf 3D EVO was first seen in early 2018, and it was notable due to the fact that it is totally loaded with features to enhance print quality and make life easier for the 3D printer operator. One feature I quite liked is the “clog-recovery” system that in some cases might enable recovery from an air-printing scenario.

EVO 3D Printer Features

![The Airwolf 3D EVO R 3D printer [Source: Airwolf 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0923cec4fb.jpg)

The other notable feature on the original EVO was its onboard heaters. While virtually all 3D printers use heated print surfaces, the EVO includes enclosure heaters that warm up the air surrounding the print. This is incredibly important to enable dimensionally accurate and geometrically correct prints, as warping is almost completely eliminated.

The original EVO is priced at just under US$8K. Shortly after releasing the EVO, Airwolf 3D announced a “stretch” version, the EVO 22, which boasts a monstrous build volume of 305 x 305 x 578 mm, and a price tag of just under US$12K.

Now the new EVO R is added to their product shelf, and it’s the opposite of the stretch EVO 22: it’s a smaller version.

Airwolf 3D EVO R Specifications

![The Airwolf 3D EVO R 3D printer [Source: Airwolf 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0923d3a6ff.jpg)

How much smaller is it? Not that much, as the original EVOs are large to start with. The EVO R has a build volume of 300 x 220 x 229 mm. That’s larger than many commonly available desktop 3D printers.

However, the EVO R includes most of the convenience and quality features of the other EVO devices:

-

Dual extruders with High-Torque Cartridge-Style Planetary Extrusion System

-

Hot end maximum temperature of 315C (Airwolf 3D says the device can 3D print over 40 different materials)

-

Minimum layer size of 0.04mm

-

Automated leveling

-

Combination HEPA/Activated Carbon filter

-

Interchangeable nozzles (0.35, 0.5, 0.8, 1.0 mm)

-

7” Color touchscreen interface

-

Heated print surface up to a searing 160C

-

Integrated camera system

-

Circuit breaker safety system

-

Resume printing after power outage

-

Hot end and heated bed overcurrent and over-temp detection circuits

-

Custom slicing software tuned to the device

-

And a host of mechanical reliability features

You may have noticed a theme flowing through those specifications: safety. The device has a number of features that should make it a very safe machine to use, and that is perhaps one reason why Airwolf 3D is targeting the device towards the education market.

I wouldn’t suggest EVO R as an introductory machine for lower grades in schools, but it would be quite appropriate for higher levels and universities where students might be exploring different engineering materials, which are easily 3D printed by the EVO R. Of course, the EVO R is also entirely suitable for use by engineers or product designers, as are the other EVO devices.

Airwolf 3D EVO R Pricing

The smaller size allowed Airwolf 3D to reduce the price of the EVO R to just under US$5K, a savings of US$3K over the larger EVO device. For many people, the already generous build volume of the EVO R will be quite sufficient.

If you’re looking for a powerful industrial 3D printer capable of reliably printing many different material types, the Airwolf 3D EVO R might be a good choice.

Via Airwolf 3D