![The D3D-s 3D Jewelry Scanner [Source: D3D-s]](https://fabbaloo.com/wp-content/uploads/2020/05/d3d-s-3d-jewelry-scanner_img_5eb0946e32260.jpg)

I’m looking at a new high-resolution tabletop 3D scanner that seems to be quite amazing.

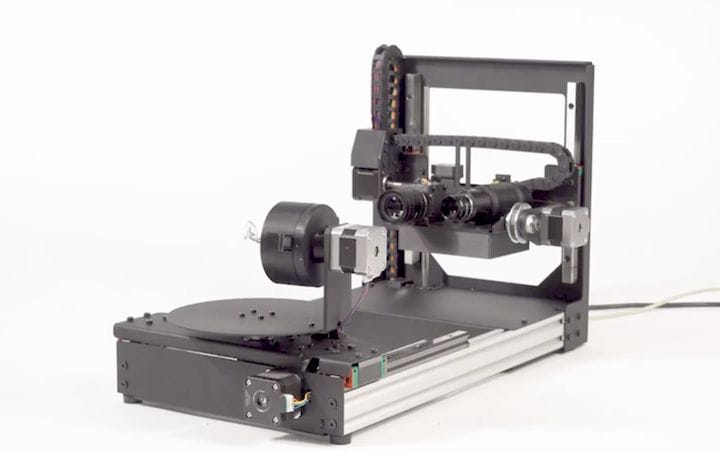

The 3D scanner in question is the new D3D-s 3D Jewelry Scanner, currently available on Kickstarter. While there are plenty of tabletop 3D scanners on the market, this one seems very different from the rest.

I’ve used several tabletop 3D scanners and have basically been dissatisfied with all of them for one reason or another. They tend to be difficult to use and most often are unable to capture the entire shape of the subject object.

The reason for this frustration is that the tabletop 3D scanners I’ve used have a rudimentary motion system that usually involves a rotating platform upon which the subject object is placed, and a fixed camera to look at the object as it spins.

This configuration inevitably results in hidden areas that are not 3D scanned: the cameras just can’t see them.

This problem seems to be solved in the D3D-s device, as it has more than two degrees of motion. In fact, it has SIX! Check out the motion system in their video here:

This is quite incredible, as it basically guarantees that a full 3D scan will be obtained. But does it really work? I have not tried the device myself, but it seems to be able to capture some amazingly complex geometries. Look at this one:

(If the embed doesn’t load for you, this is an image of the complex brooch:)

![A detailed 3D scan of a brooch [Source: D3D-s]](https://fabbaloo.com/wp-content/uploads/2020/05/d3d-s-3d-jewelry-scanner-brooch_img_5eb0946e8c59e.jpg)

This item has a large number of overhangs and hidden areas that would certainly not be properly 3D scanned by simple 2-axis 3D scanners. The company has provided several examples of complex scans such as this. Evidently the scanner software generates a complete STL file ready for use once done, as well.

D3D-s 3D Scanning Accuracy

But how accurate are these scans? They explain:

“The vertical accuracy of the D3D-s reaches 0.010 mm, and the horizontal accuracy is up to 0.015 mm. Our projector’s step resolution is 0.000625 millimeters. That’s more than 84 times the resolution of projection scanners. We even had to limit the maximum resolution in order to get you a finished result within 7 minutes. These specifications are significantly superior to all other existing scanners! This is possible because of the 5 MP camera and high-quality lens.”

Here is an example of the quality of the result, with a 3D scan of a €2 coin:

![3D scan of a €2 coin [Source: D3D-s]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0946eed18c.jpg)

In the image, please note the bumps and other physical aberrations. These, I think, are actually found on the coin itself, showing the tremendous resolution of this solution.

The D3D-s 3D Jewelry Scanner has a somewhat small scanning volume of 100mm diameter by 130mm long, so you’ll be able to use this only for smaller items, such as jewelry.

Joining 3D Models Together

One question you might be wondering about is how the scanner is able to capture the entire object when there are some clamps holding it down during the scan. Here’s their interesting answer:

“Jewelers unfamiliar with 3D scanners often wonder how to remove the clips that hold the model. The answer is very simple — scan the model twice with the clips in different places. Then use special software, such as MeshLab (a free open-source program) to combine the models and remove anything undesired.”

Low-Cost Kickstarter Campaign

One concern I always have with Kickstarter projects is whether the company is truly able to deliver on their orders. In many cases startup companies fail to understand the challenges of manufacturing at scale and somehow disappear, leaving backers very unhappy.

In this case, the team behind the D3D-s have actually done this before. They say they did successfully deliver a scanner in a previous campaign, and have learned much by doing so. They expect to have few issues meeting the orders this time around.

Now, the price. Somehow they’ve been able to produce and sell this device for a rather low price of US$8,000, with an early bird price of only US$4,000. That’s an incredible deal for a scanner of this capability.

Via Kickstarter and D3D-s